- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Application:

-

extreme environment

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

55%

-

Model Number:

-

inconel 625

-

Brand Name:

-

DZX

-

Surface:

-

Bright

-

Certificate:

-

ROHS

-

MOQ:

-

50kg

-

Ultimate Strength ( MPa):

-

≥837

-

Yield Strength(N/mm2):

-

414

-

Elongation:

-

39

-

Product name:

-

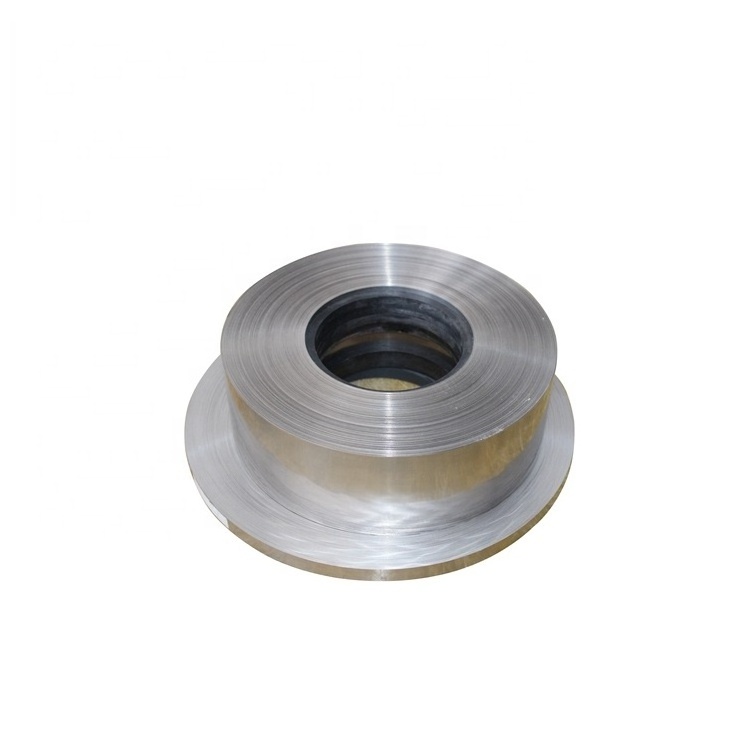

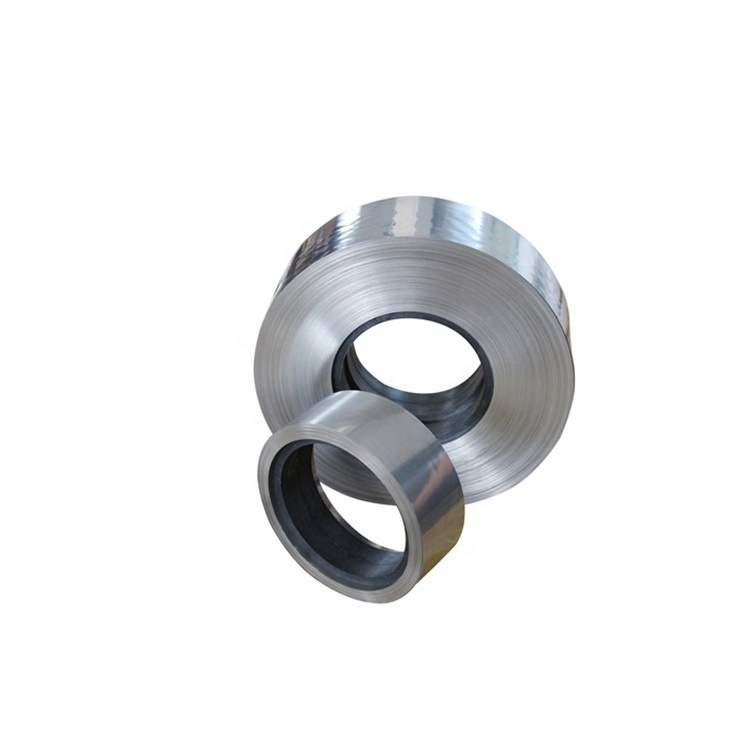

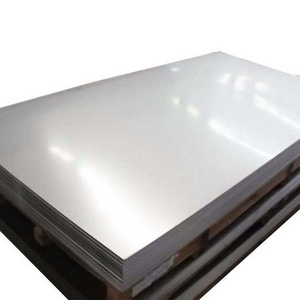

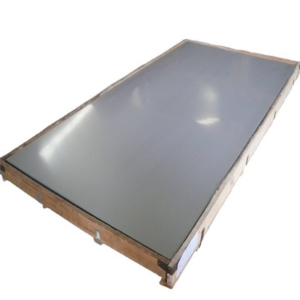

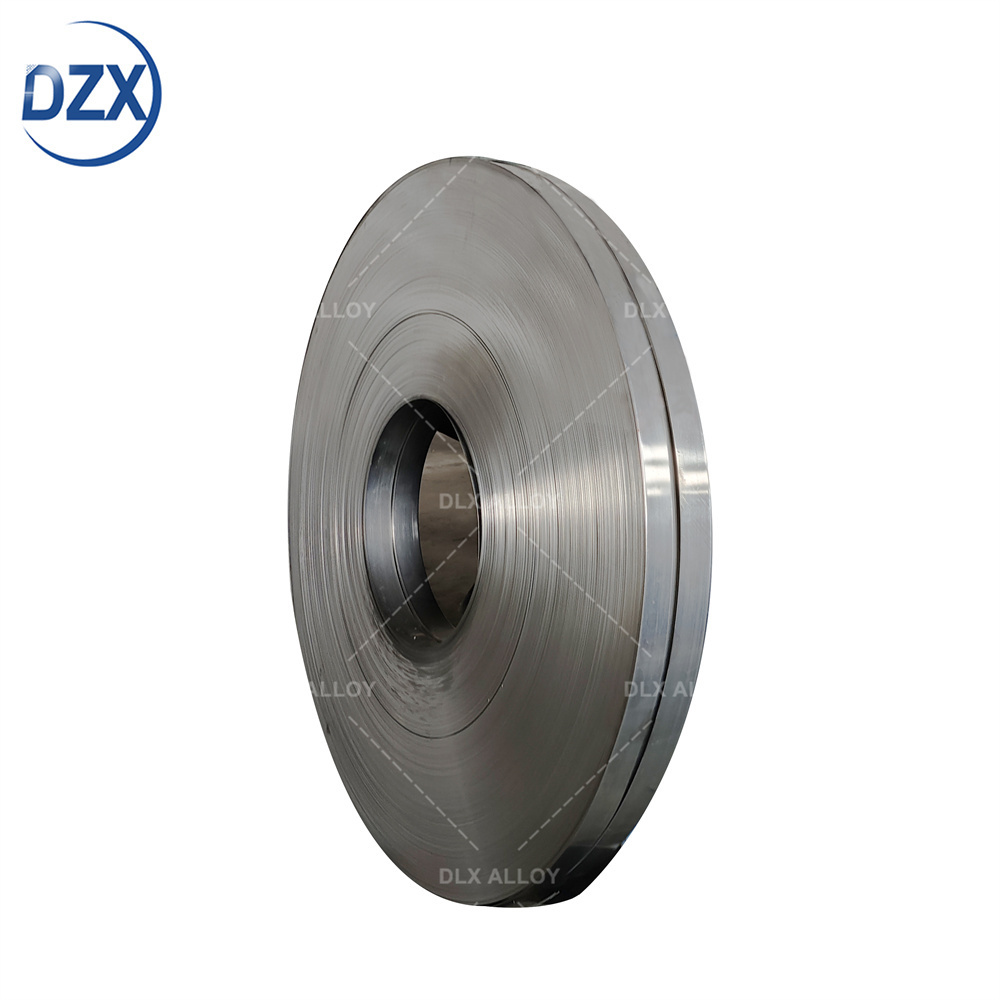

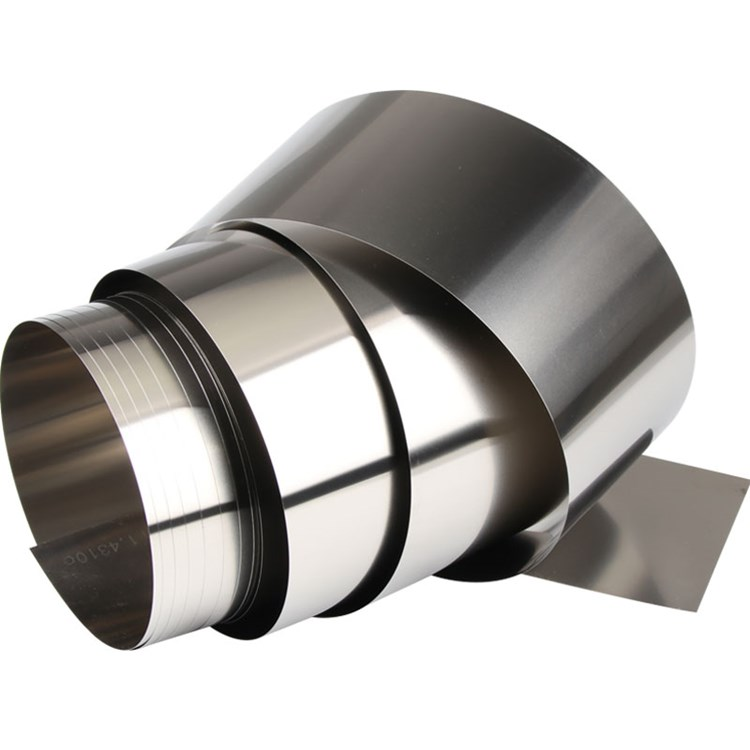

Inconel 625 Strip

Quick Details

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

837

-

Elongation (≥ %):

-

39

-

Place of Origin:

-

China

-

Application:

-

extreme environment

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

55%

-

Model Number:

-

inconel 625

-

Brand Name:

-

DZX

-

Surface:

-

Bright

-

Certificate:

-

ROHS

-

MOQ:

-

50kg

-

Ultimate Strength ( MPa):

-

≥837

-

Yield Strength(N/mm2):

-

414

-

Elongation:

-

39

-

Product name:

-

Inconel 625 Strip

Inconel 625 Strip

Inconel 625 is a nickel-based superalloy known for its exceptional corrosion resistance, high strength, and durability, making it suitable for a wide range of demanding applications. When processed into strip form, Inconel 625 strip inherits these characteristics and offers additional advantages:

1.

Corrosion Resistance

: Inconel 625 strip is highly resistant to corrosion and oxidation, even in extreme environments such as seawater and chemical processing facilities. This makes it a preferred material for applications where protection against corrosive elements is critical.

2.

High Temperature Strength:

The alloy retains its strength and structural integrity at elevated temperatures, making it

suitable for use in high-temperature environments such as aerospace applications, gas turbine components, and heat exchangers.

3.

Excellent Fatigue Resistance

: Inconel 625 strip exhibits outstanding fatigue strength, making it suitable for cyclic loading applications. This property is particularly important in industries such as aerospace and marine engineering.

Inconel 625 strip Application

2. Chemical Processing : The alloy's resistance to corrosive chemicals and high-temperature stability make it ideal for use in chemical processing equipment, including reactors, vessels, and piping systems.

3. Oil and Gas Industry : Inconel 625 strip is employed in downhole and surface applications in the oil and gas industry, where it can withstand aggressive conditions, such as corrosive fluids and high-pressure environments.

4. Power Generation : Components in power generation facilities, such as steam turbine seals and boiler components, benefit from the excellent heat and corrosion resistance of Inconel 625 strip.

|

Item

|

|

600

|

601

|

617

|

625

|

690

|

718

|

X750

|

825

|

|

|

C

|

|

≤0.15

|

≤0.1

|

0.05-0.15

|

≤0.08

|

≤0.05

|

≤0.08

|

≤0.08

|

≤0.05

|

|

|

Mn

|

|

≤1

|

≤1.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.35

|

≤1

|

≤1

|

|

|

Fe

|

|

6-10

|

rest

|

≤3

|

rest

|

7-11

|

rest

|

5-9

|

≥22

|

|

|

P

|

|

≤0.015

|

≤0.02

|

≤0.015

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|

|

S

|

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.01

|

≤0.01

|

≤0.03

|

|

|

Si

|

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.3

|

≤0.5

|

≤0.5

|

|

|

Cu

|

|

≤0.5

|

≤1

|

N/A

|

≤0.3

|

≤0.5

|

≤0.3

|

≤0.5

|

1.5-3

|

|

|

Ni

|

|

≥72

|

58-63

|

≥44.5

|

50-55

|

≥58

|

50-55

|

≥70

|

38-46

|

|

|

Co

|

|

N/A

|

N/A

|

10-15

|

≤10

|

N/A

|

≤1

|

≤1

|

N/A

|

|

|

Al

|

|

N/A

|

1-1.7

|

0.8-1.5

|

≤0.8

|

N/A

|

0.2-0.8

|

0.4-1

|

≤0.2

|

|

|

Ti

|

|

N/A

|

N/A

|

≤0.6

|

≤1.15

|

N/A

|

N/A

|

2.25-2.75

|

0.6-1.2

|

|

|

Cr

|

|

14-17

|

21-25

|

20-24

|

17-21

|

27-31

|

17-21

|

14-17

|

19.5-23.5

|

|

|

Nb+Ta

|

|

N/A

|

N/A

|

N/A

|

4.75-5.5

|

N/A

|

4.75-5.5

|

0.7-1.2

|

N/A

|

|

|

Mo

|

|

N/A

|

N/A

|

8-10

|

2.8-3.3

|

N/A

|

2.8-3.3

|

N/A

|

2.5-3.5

|

|

|

B

|

|

N/A

|

N/A

|

≤0.006

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|

|

Inconel 625 Mechanical Properties (Minimum value at 20℃)

|

|

|

||

|

Tensile Strength (σb/MPa)

|

Yield Strength (σp0.2/MPa)

|

Elongation (σ5/%)

|

||

|

827

|

414

|

30

|

||

JiangSu DZX Alloy Co.,Ltd was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate.Our factory is becoming a high-tech company,We are professional in researching and producing special alloy material.The production process include melting,drawing,heat treatment,finishing and testing.

We offer super alloy,welding wire,corrosion resistance alloy,precision alloy,FeCrAl alloy,NiCr alloy,CuNi alloy,in the form of wire,strip,ribbon,bar,tube,plate and etc.

The administrative principle of our company is "intensifying inner supervision, complying with technical process and quality control, continuously adopting new technology to ensure the product quality".