- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

lushun

-

Model Number:

-

LS-QZJ-VII

-

Place of Origin:

-

Chongqing, China

-

Usage:

-

Water

-

Power:

-

Electric

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Dry Air Volume (Kg/h):

-

≤0.5

-

Vacuum Stage:

-

Double Stage

-

Suction rate of liquid ring vacuum pump:

-

18 Kg/h

-

Extraction Rate:

-

9 Kg/h

-

Applicable Turbine Unit:

-

≤0.8 (Mega Watt) Dry Air Leakage Volume 8-9Kg/h

-

Certification:

-

ISO CE BV, CE

Quick Details

-

Application:

-

Automotive Industry, Biofuel Industry, Commercial Buildings, District Energy, Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Washing and Cleaning, wastewater treatment, Water Treatment Solutions, OTHER

-

Pressure:

-

High Pressure

-

Warranty:

-

1 years

-

Brand Name:

-

lushun

-

Model Number:

-

LS-QZJ-VII

-

Place of Origin:

-

Chongqing, China

-

Usage:

-

Water

-

Power:

-

Electric

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Dry Air Volume (Kg/h):

-

≤0.5

-

Vacuum Stage:

-

Double Stage

-

Suction rate of liquid ring vacuum pump:

-

18 Kg/h

-

Extraction Rate:

-

9 Kg/h

-

Applicable Turbine Unit:

-

≤0.8 (Mega Watt) Dry Air Leakage Volume 8-9Kg/h

-

Certification:

-

ISO CE BV, CE

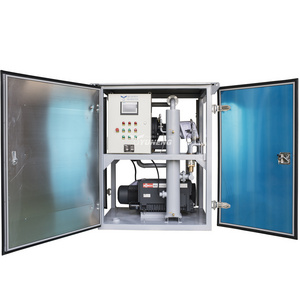

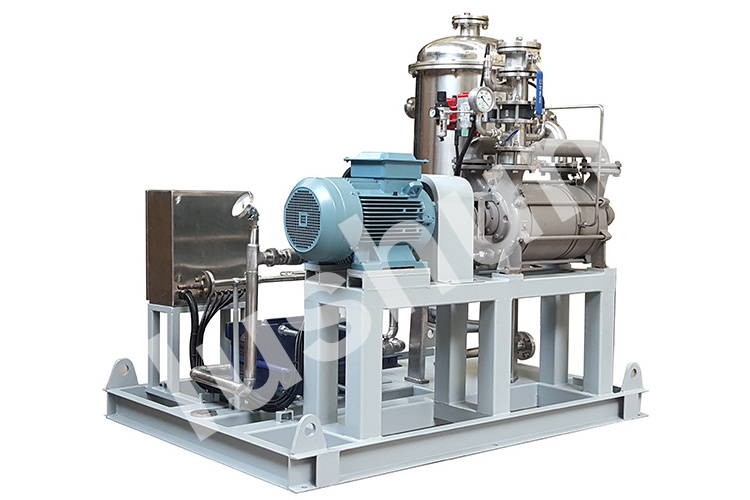

Newest Energy Saving Power Plant Vacuum Pumping and hydraulic oil flushing unitr Plant Vacuum Pumping Unit

QZJ Series Complete Water-rin g Vacuum Pump Systems are especially suitable for establishing and maintaining the vacuum condition of turbine generator sets and condenser of that. During the operation of vacuum system, it continuously suck out the air which was seeped into turbine set and its condenser from different paths . The scale of water-ring vacuum pump system adequate for condenser will be decided by the scale of in filtrated air volume of condenser. If the infiltrated air can not be sucked out in time, the stability and performance of turbine unit will be affected. For lowering the consumption and energy conservation, the better is the vacuum condition, the lower will be the steam and power consumption in power plant.

So the vacuum system for condensers is very important to power plant. It will directly affect the economical efficiency and stability of power plant operation. At present, for a lot of self-generation power plant, garbage power plant and thermal power plant, their vacuum systems are generally water-jet pumping system or steam-jet system. These systems all adopt out-dated technique and the maintenance will be very inconvenient. New power plant generally directly adopts new design of water-ring vacuum pump system.

|

Vacuum Pump Set |

Diameter of Inlet/Outlet Flange |

Total Power ( K w) |

Turbine Set ( Mega Watt ) |

Dry Air Volume ( Kg/h ) |

|

QZJ-Ⅰ |

DN 65 |

11 |

0.1-0.5 |

2- 5 |

|

QZJ-Ⅱ |

DN 80 |

15 |

0.5-0.8 |

6-8 |

|

QZJ-Ⅲ |

DN 80 |

18.5 |

0.5-0.8 |

8-10 |

|

QZJ-IV |

DN 100 |

22 |

1 . 2 |

10-12 |

|

QZJ-V |

DN 100 |

37 |

1.2-2.5 |

12-16 |

|

QZJ-VI |

DN100 |

37 |

3 |

16-20 |

|

QZJ-VII |

DN1 25 |

45 |

6 |

20-25 |

|

QZJ-VIII |

DN1 25 |

45 |

7 |

20-26 |

|

QZJ-IX |

DN1 25 |

55 |

7 |

26-30 |

|

QZJ-X |

DN1 25 |

75 |

12-15 |

30-40 |

|

QZJ-XI |

DN1 50 |

75 |

15-20 |

40-50 |

|

QZJ-XII |

DN1 50 |

110 |

30 |

50-60 |

1.The water-ring vacuum pump system adopts circulation water for cooling. The water consumption is lower without steam consumption.

2. The pump body of water-ring vacuum pump system will not be scaling as water-jet pump(especially in the situation of bad water quality). So the maintenance work will be much more less for water-ring vacuum pump system.

3. Operation is simple and it can support operation without supervision and realize DCS remote control.

4. Easy Maintenance

5.Less land occupation and easy installation and connection.

6. They are the first choice for existing power plant condenser vacuum pump system renovation project and new power plant project condenser vacuum pump system.

7. The vacuum degree of water-ring vacuum pump system can achieve -93Kpa or lower. The exact vacuum degree will depend on the on-site situation and cooling agent temperature.

Welcome to visit our website, welcome your inquiry.

Contact Person: Mr. Daniel Yang

Email: sale @lushuntec.com

Tell: +86-23-65226016 / 65226026 / 65227191 / +86-13650521202

Fax: +86-23-65226013

Address: No. 1,Sendi Road, Xipeng Town, Jiulongpo District, Chongqing

Web:https: //www.cnlushuntec.com