- Product Details

- {{item.text}}

Quick Details

-

Material:

-

FRP, PVC, PTEF, Carbon steel and Stainless steel

-

Weight:

-

None

-

Size:

-

Dia.1000,1500,2000,2200,2500,3000,3200mm

-

Power:

-

None

-

Weight (KG):

-

20 kg

-

Application:

-

Transport and dilute regeneration liquid in water treatment system

Quick Details

-

Core Components:

-

None

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

KAITE

-

Material:

-

FRP, PVC, PTEF, Carbon steel and Stainless steel

-

Weight:

-

None

-

Size:

-

Dia.1000,1500,2000,2200,2500,3000,3200mm

-

Power:

-

None

-

Weight (KG):

-

20 kg

-

Application:

-

Transport and dilute regeneration liquid in water treatment system

WNP type ejector (the original WGP type) is the equipment for conveying and diluting the regenerated liquid in the water treatment system. When the water production stage of the anion and cation exchanger is over, the ions in the exchanger have been in a failed state, and the ion exchange resin must be regenerated to restore the regeneration ability of the ion exchange resin. The cation and anion exchange resins are usually regenerated with low concentration acid and base solutions.

WNP type injector is made of FRP, PVC, PTEF, carbon steel and stainless steel and other materials, we can make according to the actual needs and drawings of customers.

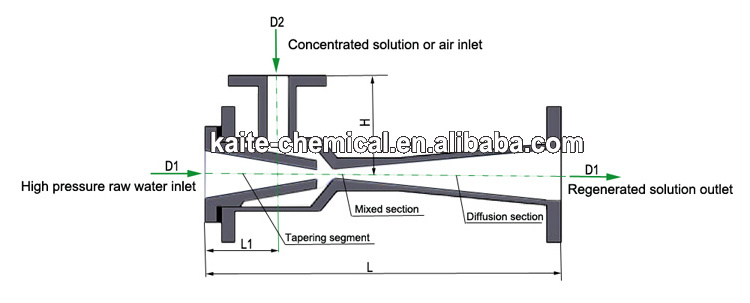

Working principle

The high pressure raw water enters the tapering segment of the injector through the pipe valve, converts the static pressure head into kinetic energy, and becomes a high-speed jet at the nozzle, forming a micro vacuum state in the mixing chamber, and inhales the high concentration of regenerated pharmaceutical liquid into the mixing chamber, and changes the pressure and speed of the regenerated pharmaceutical liquid. In the mixing section, water and pharmaceutical liquid are fully mixed, and then flow through the diffusion section to reduce the flow rate of the regenerated liquid, the static pressure head is raised, and then the diluted regenerated liquid is sent to the exchanger body through the outlet pipe and valve.

Usage method

We can make the export liquid reach the required concentration by adjusting the inlet valve of the concentrated solution and adjusting the thickness of the gasket.

Note: Special attention should be paid to the parallelism and verticality between the injector flange and the connecting iron flange during installation.

At present, the WNP injector is the necessary equipment in the chemical water treatment system, and the injector is mostly used in the configuration and transportation of recycled liquid. It has the advantages of reasonable design, compact structure, easy operation, good mixing effect and long service life.

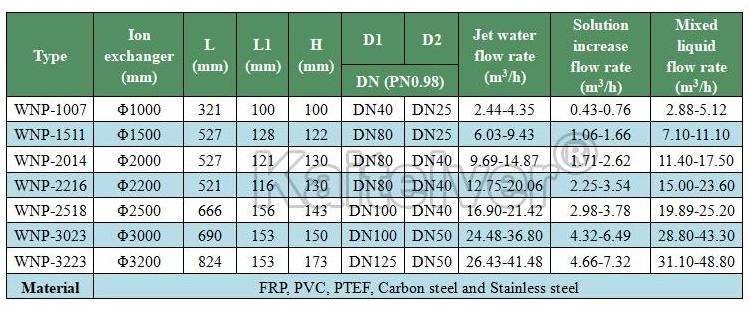

|

Extraction Gas Flow Rate |

||||||||||

|

Type |

WNP-1007 |

WNP-1511 |

WNP-2014 |

WNP-2216 |

WNP-2518 |

WNP-3023 |

WNP-3223 |

|||

|

Air |

26.49 |

26.49 |

47.57 |

47.57 |

47.57 |

105.98 |

105.98 |

|||

|

Chlorine |

10.86 |

10.86 |

19.50 |

19.50 |

19.50 |

43.45 |

43.45 |

|||

|

Ozone |

15.89 |

15.89 |

28.54 |

28.54 |

63.59 |

63.59 |

63.59 |

|||

|

High pressure raw water pressure (MPa) |

Regenerative solution outlet pressure (MPa) |

Solution inlet concentration (%) |

Regenerated solution outlet concentration (%) |

|||||||

|

NaOH |

HCL |

|||||||||

|

0.196-0.392 |

0.120-0.196 |

40 |

30 |

2.5-5.0 |

||||||