- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Construction Waterproof

-

Applicable materials:

-

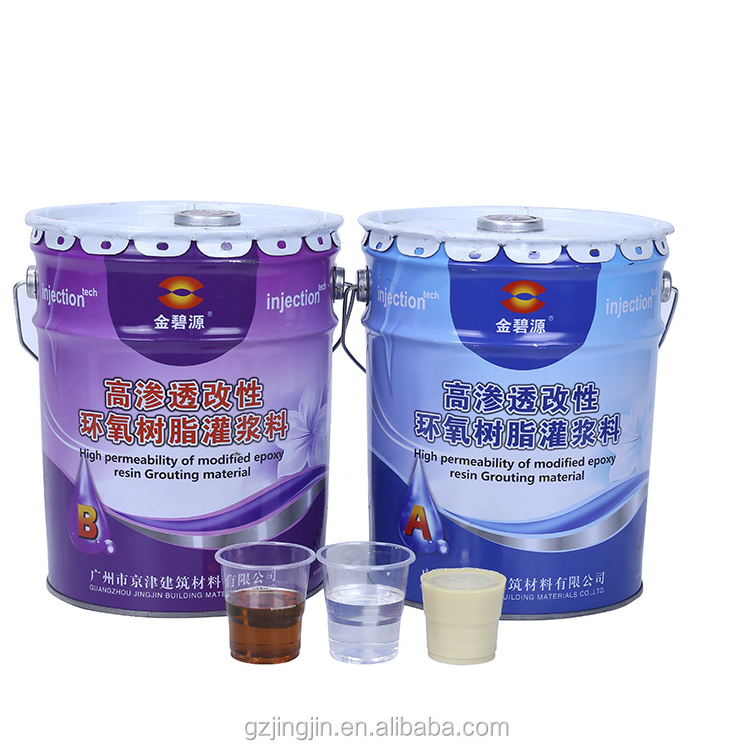

Epoxy Resin, Polyurethane

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JBY

-

Weight:

-

8kg

-

Application:

-

Construction Waterproof

-

Applicable materials:

-

Epoxy Resin, Polyurethane

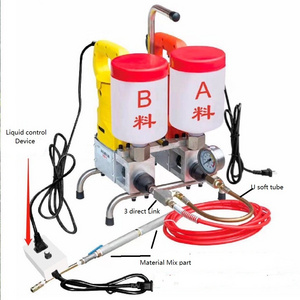

Two Components Polyurethane and Epoxy Resin Injection Pump For Leak Stoppage

Double-liquid grouting machine with the sophisticated & proper design easy to carry and portable, the special material of wear resistant, the high-pressure perfusion & spraying machine are successfully developed. Also, it excludes the previous many defects and is a professional machine for structure reinforcement, leak stoppage, spraying for head-resistant materials with quick disassembly, easy to maintain & super high pressure. The parts of machine aren’t deformed when being injected. Besides, it can avoid the inconvenience of heavy machinery for workers and is the best tool for the persons who work on the professional water-sealing project.

Fast Construction: upgrade to 0 ~ 6000spi work pressure in a few seconds, faster than other models on perfusion.

Light weight: weighing of machine body being only 13 kg, portable, easy to move.

Durability:

when the pressure is up to 8000psi (Max), the parts of the body will keep their shapes.

Simple Repair: it can be repaired in the construction site, avoiding stopping working because of sending for maintenance due to mechanical failure.

1:1 matching double-liquid non particle low-viscosity liquid.

1. Double liquid-type PU Foam Waterproofing plugging agent, insulation material,

2. Double liquid-type quick-setting PU/EPOXY reinforcing agent

|

Double liquid grouting machine |

|

|

Net weight |

13kg |

|

Maximum output pressure |

10000psi |

|

Pressure of starting again |

less than 7500psi |

|

Safe range of high-pressure pipe |

less than 10000psi |

|

safe range of switch valve |

less than 15000psi |

|

the length of hose |

5m |

|

Power |

690w/220v |

Leakage blocking, strengthening and reinforcing for subway tunnel, culvert, structure hives, crack, second construction joint and so on.

A + B agent separately pours into the feed cup. Firstly, turn off the switch of straw and insert the double-liquid needle locked, start the power switch and inject the water-sealing agent into the body for leak stoppage & reinforcement. When spraying Double-liquid foam agent, the air compressor shall be opened continually, avoiding hardening & jam of spraying nozzle. Whether the operation surface of spraying is clean or not depends on the thickness of coating. Spray directly the spray fabric on the construction surface 2 ~ 3 pass. The second pass of spraying is after the completion of hardening of the first spraying.

Contact me: Rachel

Tel/wechat:+86 18617352817