- Product Details

- {{item.text}}

Quick Details

-

Certification:

-

API

Quick Details

-

Weight (KG):

-

80

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OEM

-

Certification:

-

API

Application for bit

In Petroleum & Gas ,Water well ,Mining and Tectonic Industries ,Oil field, Construction, Geothermal, Directional Boring, and Underground Foundation work.

| DTH hammer type | HD35 | HD45 | HSD4 | HQL4 | |

| Length(less bit) mm | 930mm | 1030 | 1084 | 1097 | |

| Weight(less bit) kg | 25kg | 39 | 40.5 | 41 | |

| External diameter mm | Φ82mm | Φ99 | Φ99 | Φ99 | |

| Bit shank | DHD3.5 | COP44 DHD340 | SD4 | QL40 | |

| Hole range(mm) | Φ90-110 | Φ110-135 | Φ110-135 | Φ110-135 | |

| Connection thread | API 23/8" Reg. | API 2 3/8"Reg | API 2 3/8"Reg | API 2 3/8"Reg | |

| Working pressure | 1.0-1.5Mpa | 1.0-2.5Mpa | 1.0-2.5Mpa | 1.0-2.5Mpa | |

| Impact rate at 1.5-1.7Mpa | 28Hz | 27Hz | 27Hz | 27Hz | |

| Recommended Rotation speed | 25-40r/min | 25-40r/min | 25-40r/min | 25-40r/min | |

| Air consumption | 1.0Mpa | 4.5m3/min | 6.0m3/min | 6.0m3/min | 6.0m3/min |

| 1.8Mpa | 9.0m3/min | 10.0m3/min | 10.0m3/min | 10.0m3/min | |

| 2.4Mpa | / | 15.0m3/min | 15.0m3/min | 15.0m3/min | |

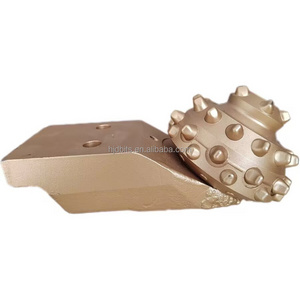

Introduction about rock drill bit:

1,Include single rock bit,tricone rock bit and assemble rock bit. And steel tooth rock bit,insert rock bit.

2,Rock bit is the most widely used, Cone bit work cutting teeth alternating contact the bottom of the well, the rock breaking torque is small, contacting area is small, high specific pressure, easy to eat into the stratum; the total length of working edge is big, so relatively reduce wear. Cone bit can adapt to a variety of formation from soft to hard

The bit structure

Cone bit is composed by cutting structure, bearing structure, the locking element and oil sealing device, nozzle device, more than 20 kinds of parts .

The leg material is 15CrNiMo,a tricone bit is composed of 3 legs.The cone material is 15CrNi4Mo.The tooth type is include steel tooth and insert tooth.Insert tooth is punch in outside of the cone.The steel tooth is milled from the cone directly.the tooth is engage each other,

Can break comprehensive rock effectively and without repeated and prevent alveolar mudbag .

Bit tooth shape, size, quantity, depending on the drilled strata hardness, formation is soft, then the teeth larger and more pointed, the fewer quantity.

Roller arrangement:

1,Non self washing no slide layout:suitable for hard formations.

2,Self cleaning does not shift shaft arrangement: suitable for medium formations.

Beraing of bit :

Bearing structure include Cone cavity, claw shaft neck, bearing the runway, the locking element . Each cone has large, medium and small and the thrust bearing ,toal four paybearing. Big, small bearings bear radial load; medium bearing used in locking and positioning;thrust bearing bear axial load.

Oil lubrication sealing system:

Sealing system include two types : O-ring sealed ,metal sealed.

operational principle :Oil pressure compensation system (the pressure transmission hole, pressure compensation film, oil etc.) to keep equilibrium between the oil and fluid pressure in the well .When oil pressure reduce , oil in storage cup is added into bearing cavity in the effect of drilling fluid column pressure.When Oil pressure of the bearing cavity increase, oil fluid into the cup.So,well sealed is very important.

Different tooth corresponding different formation oil water well drilling bit oil gas drilling equipment tricone rock bit