- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CNJW

-

Surface Treatment:

-

Smooth

-

Product name:

-

DN50~4000 FRP GRP Pipe Filament Winding Machine

-

Standard:

-

GB/T21238,Awwa C950,ASTM D2996

-

Specification:

-

DN50-DN4000mm

-

Long Life Aftersales Service:

-

Long Life Aftersales Service

-

Material:

-

Steel

-

Customized:

-

Yes

Quick Details

-

Application:

-

Sewage,Drinking Water,Corrosive Liquid or Gas

-

Technique:

-

FRP Continuous Production

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CNJW

-

Surface Treatment:

-

Smooth

-

Product name:

-

DN50~4000 FRP GRP Pipe Filament Winding Machine

-

Standard:

-

GB/T21238,Awwa C950,ASTM D2996

-

Specification:

-

DN50-DN4000mm

-

Long Life Aftersales Service:

-

Long Life Aftersales Service

-

Material:

-

Steel

-

Customized:

-

Yes

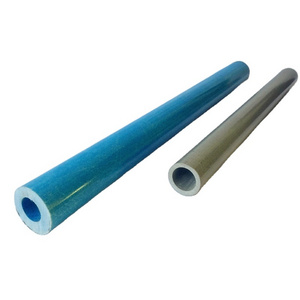

FRP GRP Fiberglass pipes winding machine, FRP septic tank and storage tank production equipment, FRP GRP Pipes Tanks Moulds

QFW-4000VI RPM Pipe Production Line

The QFW-4000VI RPM Pipe (Reinforced Plastics Mortar Pipe) Production Line has six parts, such as inner layer manufacturing machine, computer control adding mortar-winding machine, curing station, repairing machine, mould unloading machine and resin mix station. Its controlling center has been adopted the Taiwan's advanced STD industrial control computer. If the parameter of the wound products being inputted the computer, the design of the linearity for winding of the product will be finished automatically, then controlling the combined movements between the mound rolling speed and the running of the carriage. The pipes produced by the adding mortar-winding machine can decrease the cost and improve the stiffness through adding the mortar without bad influences upon the leak-proof layer and the structure layer.

The RPM pipe's cost has decreased 40% than the common FRP pipe; the stiffness has been improved greatly. It has many advantages, such as lightweight, anti-corrosion, lower roughness and proper price. It can be widely used in water supply and drainage, agricultural irrigation, petrochemical industry, ocean development, sewage treatment, etc. The production line annual capacity is 5000t, and reasonable structures, latest design, operate easily, high-grade automation are its characteristics.It got the good valuation from the clients.

The main parameters :

| Iterms | Value |

| The total power | 193.6kw |

| The maximum diameter can be manufactured | DN4000mm |

| The effective length of the pipe | 12000mm |

| The productivity | 1000kg/h |

| The baking board's temperature of curing station | 105-160ºC |

| The maxi speed of conveying roving | 90m/min |

| The maxi width of roving sheet | 200mm |

| The maxi speed of sand conveyance | 100kg/min |

| The maxi mould-unloading force | 83t |

| The rated drawing force of the capstan | 5t |

| The rated lifting force of the supporting pipe trolley | 40t |

| The rated pressure of the hydraulic system | 16Mpa |

| The central height of mould-unloading machine | 2000mm |

| The central height of the other single machine | 1500mm |

Q: Can your factory provide customized services?

A: Yes, we can. From small parts to large machines, we can provide most kinds of customized services.

Q: Can you do OEM?

A: Yes, we can offer OEM & ODM.

Q: l am interested in your products, can l have a sample for free?

A: We could offer that.

Q: What is your payment term?

A: L/C, T/T.

Q: What about the delivery?

A: lt depends on the product performance and quantity you need. Because we are the expert, the production time won't take so long.