- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

250kg

-

Size:

-

Customized

-

Power:

-

Customized

-

Weight (KG):

-

250 kg

-

Operation:

-

Fully automatic

-

Advantages:

-

No clogging

-

Features:

-

Energy saving

-

Processing:

-

laser cutting

-

Product name:

-

Sludge Dewatering Machine

-

Application:

-

Wastewater Treatment

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MYEP

-

Material:

-

Wood package, SS304 or SS316

-

Weight:

-

250kg

-

Size:

-

Customized

-

Power:

-

Customized

-

Weight (KG):

-

250 kg

-

Operation:

-

Fully automatic

-

Advantages:

-

No clogging

-

Features:

-

Energy saving

-

Processing:

-

laser cutting

-

Product name:

-

Sludge Dewatering Machine

-

Application:

-

Wastewater Treatment

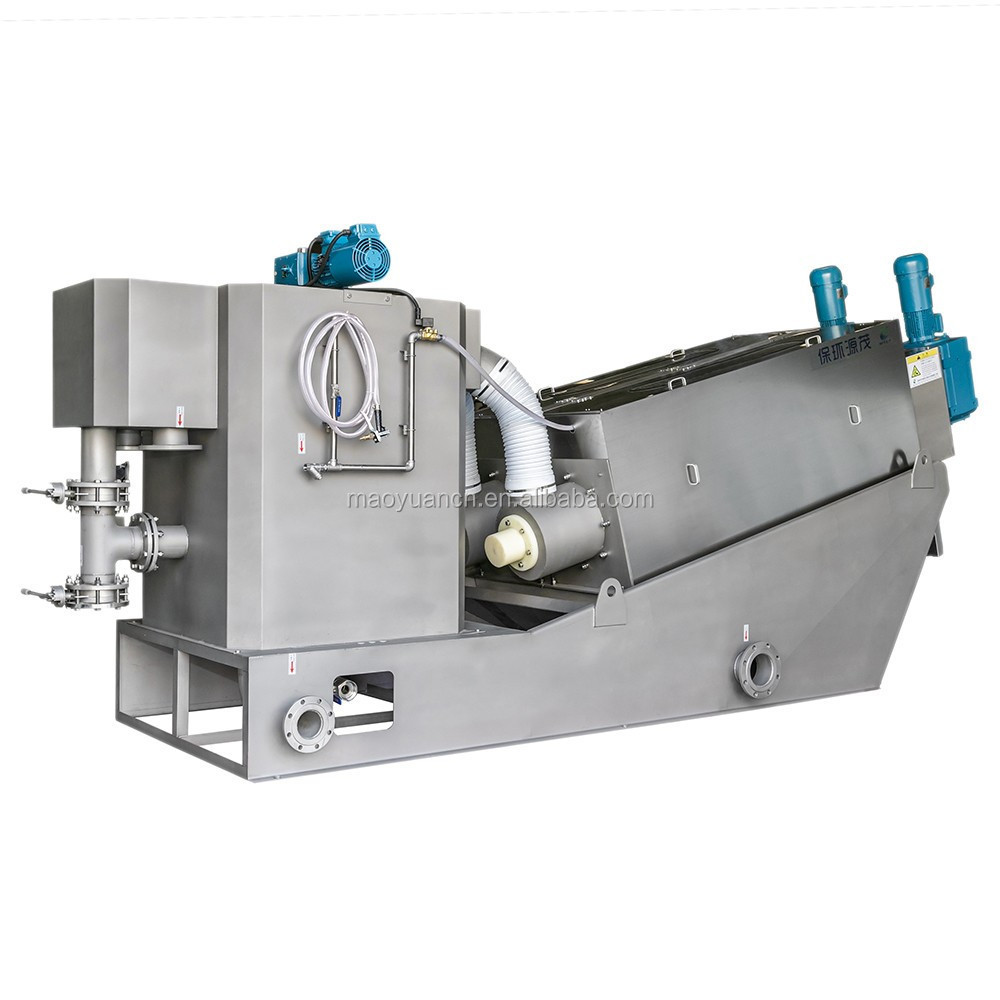

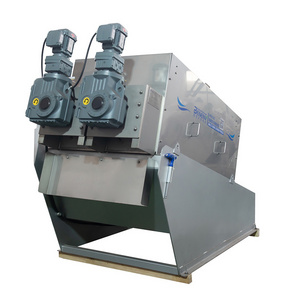

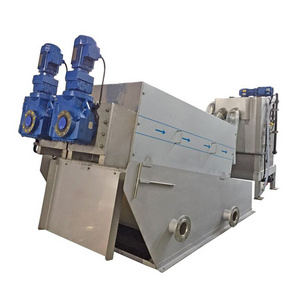

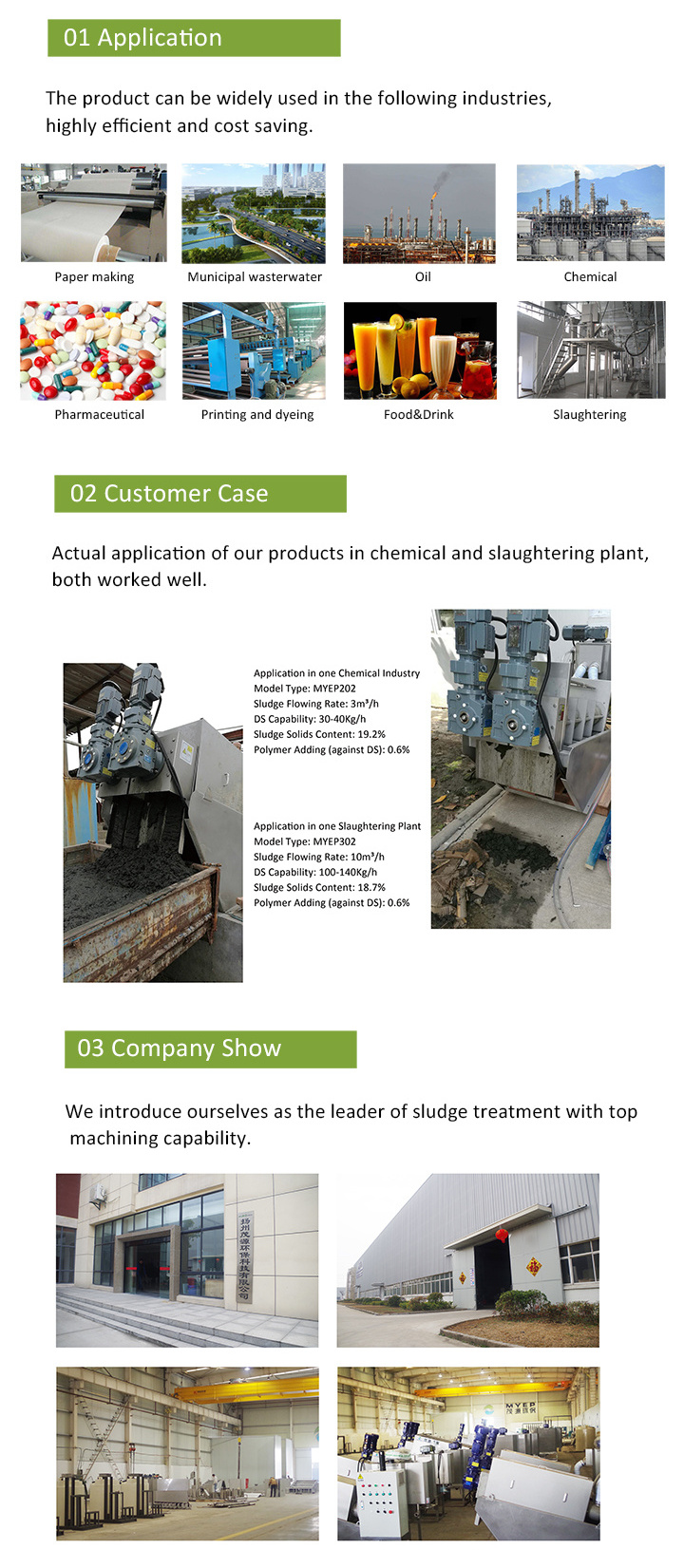

Water Treatment Equipment Filter Press Multi-disk Screw Press for Sludge Dewatering Application

, is a new type of dewatering equipment, is widely used to dewater sludge n the following industries including chemical, paper-making, pharmacy, leather and etc. This

New Generation Sludge Dewatering Machine for Sludge Dewatering Application

can run automatically for 24 hours without looking compared to traditional types.

Its great features include:

1. Jam Resistance

Low volume of flush water required so as to save the water cost and lower the internal circulation burden caused by the flush water.

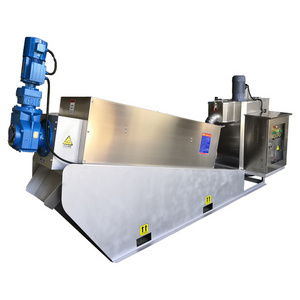

2. Less Covering Space

Electric control panel, flocculation Mixing tank and the dewatering body are integrated as one. So as to save the covering

space which makes the installing much easier.

3. Better Working Environment

This equipment adopts closed operation mode. It treats the sludge stably and in time. The advantage of reducing the smell

on spot provides a better working environment for the workers.

4. Easy to Operate, Easy to Maintain

Realize automatic operation for 24hours so as to release the operation staff from heavy labor. And the design is convenient for daily maintenance.

5. Cost Saving

The screw shaft operates in low speed which consumes little power. Vibration or noise are both hardly existed on spot.

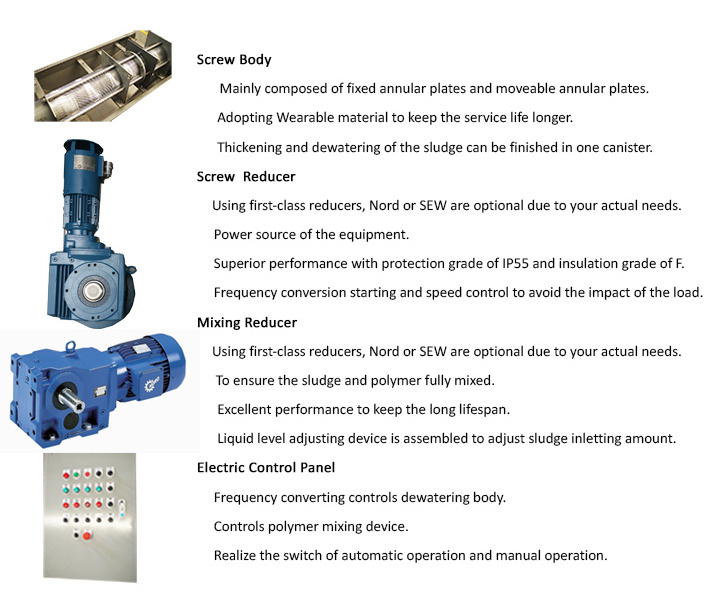

Product Details

Working Principle

Thickening

:

When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water

is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering

:

The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With

the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher.

In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Why Us

SATISFACTORY SERVICE

ADVANCED DEWATERING TECHNOLOGY

About Model Selection

| Main Specifications | ||

| Design Parameter | Capability | 10-480kgds/h |

| Total Power | 0.36-6kw | |

| Protection Grade |

Protection Grade: IP55

Insulation Grade: F |

|

| Power Supply | According to actual usage | |

| Output Moisture Content | 75-85% | |

| Polymer Feeding Rate | DS 0.2~1% | |

| Screw Body | Quantity | 1-3 |

| Material |

Plate: SUS304

Screw Shaft: SUS304 |

|

| Flocculation Mixing tank | Volume | About 40-1500L |

| Material | SUS304 | |

Full Model List

| Model | Dry Solids Capacity | Dimension | Weight | Motor Power | |||

| (Kg-DS/hr) | (mm) | (Kg) | (Kw ) | ||||

| (L) | (W) | (H) | Net | Operating | Total | ||

| MYEP131 | 10-14 | 2000 | 750 | 1080 | 230 | 310 | 0.36 |

| MYEP201 | 15-20 | 2450 | 780 | 1210 | 370 | 540 | 0.55 |

| MYEP202 | 30-40 | 2560 | 1010 | 1210 | 570 | 660 | 1.29 |

| MYEP203 | 45-60 | 2550 | 1450 | 1500 | 700 | 1010 | 1.66 |

| MYEP301 | 50-70 | 3345 | 890 | 1850 | 780 | 1300 | 1.3 |

| MYEP302 | 100-140 | 3545 | 1240 | 1850 | 1250 | 2000 | 2.25 |

| MYEP303 | 150-210 | 3700 | 1610 | 1850 | 1700 | 2700 | 3.35 |

| MYEP304 | 200-280 | 3850 | 1985 | 1850 | 2300 | 3600 | 4.1 |

| MYEP351 | 100-120 | 3895 | 1070 | 2130 | 1100 | 2000 | 1.85 |

| MYEP352 | 200-240 | 4150 | 1425 | 2130 | 2100 | 3250 | 3.3 |

| MYEP353 | 300-360 | 4242 | 1865 | 2130 | 3100 | 4600 | 4.8 |

| MYEP354 | 400-480 | 4250 | 2285 | 2130 | 4100 | 5700 | 6.6 |

| MYEP401 | 120-150 | 4630 | 1240 | 2200 | 2800 | 4800 | 2.6 |

| MYEP402 | 260-320 | 4880 | 1680 | 2200 | 3800 | 6000 | 4.1 |

| MYEP403 | 390-480 | 4910 | 2184 | 2100 | 4500 | 6000 | 6.0 |

and so on, so that we can advise you the most suitable model.

Company Strength

FAQ

Q1. Are you a factory or a trading company?

A: We belong to a factory, so we can control every aspect of the product and provide the best quality with lowest price for you.

Q2. How do you ship the goods and how long does it take to arrive?

A: Airline and sea shipping also optional. Shipping time depends on distance.

Q3. Is it OK to print my logo on the product?

A: Yes, but inform us formally before our production.

Q4. Is there any other equipment used in sludge treatment?

A: Yes, including polymer dosing system, sludge thickener, conveying device, rotary drum screen, coarse screen, p addle

dryer, dissolved air flotation , s ludge scraper bridge and etc. If you are interested, contact us for further information.

Thank you for visiting our site, please feel free to contact us if you have further questions. Find me by the following methods, or write down your requirements below, we will always be happy to answer your questions.