- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SNT

-

Voltage:

-

220V/380V 50Hz or customized

-

Power:

-

166 Kw

-

Dimension(L*W*H):

-

42 x 3 x 3.5m or customized

-

Weight:

-

30000 KG

-

Marketing Type:

-

Hot product 2023

-

Core Components:

-

Extruding system and temperature control

-

Application:

-

Italian short pasta macaroni processing machinery

-

Feature:

-

High automation, easy operation and maintenance

-

Device material:

-

stainless steel 304, carbon steel, non-posionous rubber belt, etc.

-

Operator:

-

7+ per shift

-

Steam:

-

500Kg/h

-

Water:

-

3/10

-

Raw material:

-

Durum, Semolina, Wheat flour, etc

-

Final product:

-

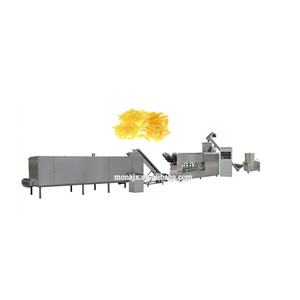

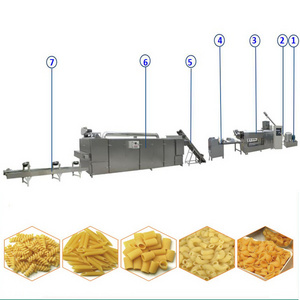

Dried macaroni, elbow, fusilli, shell, etc.

-

After Warranty Service:

-

Video technical support on line, long life paid spare parts prpovided

Quick Details

-

Production Capacity:

-

300 kg raw material each hour

-

Type:

-

pasta, Grain Processing Equipment

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

SNT

-

Voltage:

-

220V/380V 50Hz or customized

-

Power:

-

166 Kw

-

Dimension(L*W*H):

-

42 x 3 x 3.5m or customized

-

Weight:

-

30000 KG

-

Marketing Type:

-

Hot product 2023

-

Core Components:

-

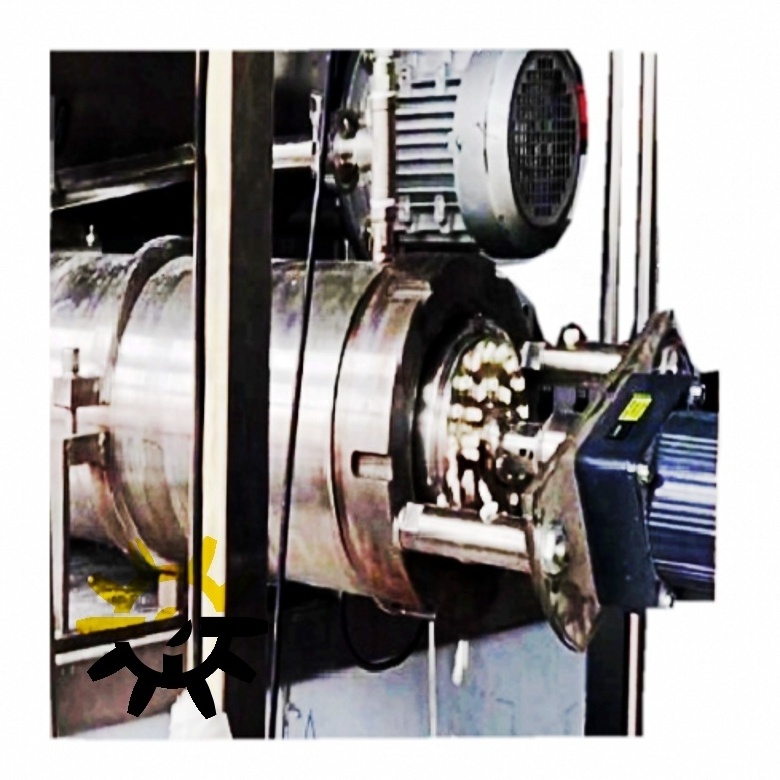

Extruding system and temperature control

-

Application:

-

Italian short pasta macaroni processing machinery

-

Feature:

-

High automation, easy operation and maintenance

-

Device material:

-

stainless steel 304, carbon steel, non-posionous rubber belt, etc.

-

Operator:

-

7+ per shift

-

Steam:

-

500Kg/h

-

Water:

-

3/10

-

Raw material:

-

Durum, Semolina, Wheat flour, etc

-

Final product:

-

Dried macaroni, elbow, fusilli, shell, etc.

-

After Warranty Service:

-

Video technical support on line, long life paid spare parts prpovided

Automatic macaroni pasta making machine/Commercial industrial short cut pasta production line for elbow fusilli macaroni shell spiral processing which is explored by SNT is innovated from the oringinal processing technique by twice extrusion. The whole production line is highly controlled automatically from flour feeding to the final products, less manual operation. The operators only need to observe, monitor and adjust the equipments, which saves a lots of labors and reduce the cost .

The Main Features for the industrial short cut pasta macaroni fusilli production line

1.Innovate the tradition processing method by twice extrusions, pasta with excecllent

cooking performnance;

2. Great flexibility in the changeover of product shape;

3. Stable running;

4. Shorter drying and processing time;

5. Energy saving design;

6. Easy clean and maintenance.

Main processing produce for macaroni manufacturing

Auto flour supplying system --- water dosing --- vacuum mixing --- rationing feeding --- short cut Italian pasta macaroni fusilli forming --- rationing cutting --- vibrating conveying --- lifting --- continuous pre-drying --- continuous drying --- conditional cooling --- storage (Optional device) --- auto-scale & packaging (Optional device) --- production conveyor

Compreshesion service system

1. Supply solutions according to the buyer's special demands;

2. Design the total installation of the manufacturing line;

3. Supply information of the related device;

4. Provide the technicial assistance at check-up and start up;

5. Provide the local operators training.

6. One year warranty and long life paid maintenance.

Booth at the Canton Fair

Excellent pre-sales to after-sales service

1. Supply solutions according to the buyer's special demands;

2. Provide the professional suggestion from A to Z;

3. Supply information of the related device;

4. Provide the technicial assistance both at check-up and startup;

5. Train the local operators.