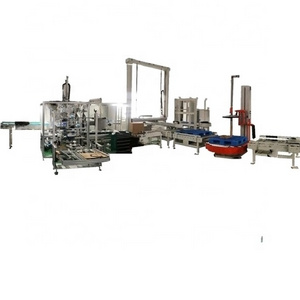

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINYEQING

-

Weight:

-

12000 KG

-

Keywords:

-

Flooring Locking Flooring packing machine

-

Packing speed:

-

8-12 Cases/min

-

Suitable for:

-

SPC WPC LVT flooring

-

Other name:

-

Pllletizer Machine

-

Relevant Corollary Equipment:

-

Extruder

-

Function:

-

Automatic Carton Packaging Line

-

Product name:

-

Automatic Cartoning Machine

-

Application Fields:

-

carton box packing stacking

-

Object to be transported:

-

Turnover Box

-

Palletizing parameters:

-

Automatic Programming

Quick Details

-

Application:

-

Food, Beverage, Chemical, Machinery & Hardware, flooring factory

-

Packaging Material:

-

Plastic, Wood, carton case

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINYEQING

-

Weight:

-

12000 KG

-

Keywords:

-

Flooring Locking Flooring packing machine

-

Packing speed:

-

8-12 Cases/min

-

Suitable for:

-

SPC WPC LVT flooring

-

Other name:

-

Pllletizer Machine

-

Relevant Corollary Equipment:

-

Extruder

-

Function:

-

Automatic Carton Packaging Line

-

Product name:

-

Automatic Cartoning Machine

-

Application Fields:

-

carton box packing stacking

-

Object to be transported:

-

Turnover Box

-

Palletizing parameters:

-

Automatic Programming

Products Description

The R-series high speed LVT/WPC/SPC hot melt glue automatic packing machine which was produced bu suzhou xinyeqing ltd .Its use PLC intelligent modules control system and precision sprocket chuck drive mechanism.Cooper with hot melt glue machine and high precision spray gun ,through intermittent spraying function to achieve 8-10 packages per minute speed. Directly connect with slotting machine and film laminating machine .Meanwhile, it can set a variety packing sizes on one machine .convenient adjustment ,easy operation .The floor automatic packing palletizer can be use alone ,also can be used with the silence pad laminer and slotted machine .Its was flexibly used according to production requirements.

Working process

The plastic floors were stacked and positioned ,then feed into machine inside by the roller conveyor. And the plastic floor

cardboard were sucked into the machine through the feeding device .the plastic floor were feed into the cardboard by a push rod and chain delivery .At each packing station ,the sides and upper and lower side of the cardboard are automatically formed and fixed by glue .after forming ,the package were sent out of the machine by the roller conveyor belt into automatic palletizer .

Technical Specification

|

Automatic packaging machine

|

|

|

|

|

||||

|

Packaging length

|

|

900mm---1600mm

|

|

|

||||

|

Packaging width

|

|

120mm---240mm

|

|

|

||||

|

Packaging height

|

|

40mm---80mm

|

|

|

||||

|

Packing speed

|

|

8---10 packs/min

|

|

|

||||

|

Carton storage capacity

|

|

300

|

|

|

||||

|

Double station palletizing

|

|

|

|

|

||||

More product advantages

1.The autaomatic machines brings smooth and efficient packing process .

2.Servo control drive structure,increase the stability and fluency packing.

3.PLC intelligent control ,high stability and repeatability .

4.Friendly touch screen interface for easier operation .

5.Advanced design ,quick and easy to adjust a variety of floor packing specifications.

6.

International brand components used to ensure machines quality stable and reliable.

Hot Searches