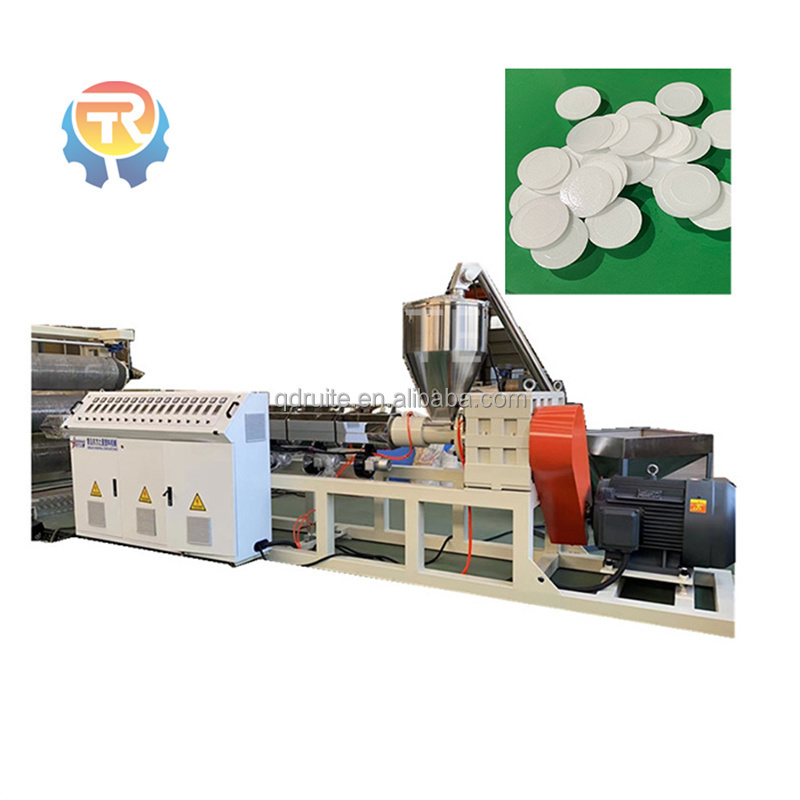

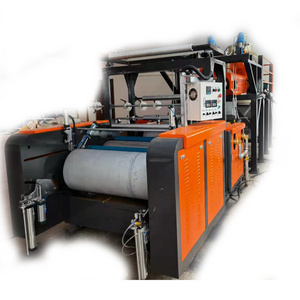

1)motor 90kw

2)raw material:

APET PETG CPET

3)output:200-250kgs/h

4)factory site demand:

22000×3200×3300mm

5) extruder motor:185kw

6) electric brands: OMRON, ABB, SHNEIDER,SIEMENS, DELTA etc.