Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different Material can also be used in combination.

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

8000kg

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Voltage:

-

220V/380V/415V/customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

3 kW

-

Product name:

-

ribon mixer

-

material applied mixing:

-

flour, powder, pellet

-

Function:

-

Mixer Blender

-

Power(W):

-

3-55KW

Quick Details

-

Barrel Volume (L):

-

50-10000 L

-

Max. Loading Volume (L):

-

8000 L

-

Range of Spindle Speed(r.p.m):

-

22 - 42 r.p.m

-

Max. Loading Capacity:

-

8000kg

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Voltage:

-

220V/380V/415V/customized

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

3 kW

-

Product name:

-

ribon mixer

-

material applied mixing:

-

flour, powder, pellet

-

Function:

-

Mixer Blender

-

Power(W):

-

3-55KW

Products Description

DZJX

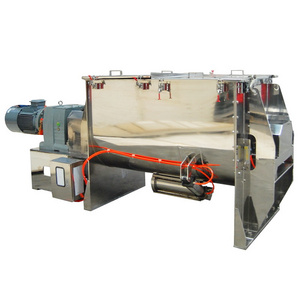

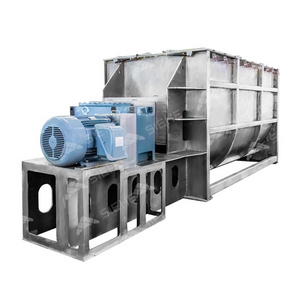

100 500 5000 Liter Food Powder Horizontal Ribbon Blender Mixer Powder Mixing Machine 100 Kg Stainless Steel Ribbon Mixer

Horizontal Ribbon Mixer is a pioneer product researched and a new high-efficiency mixer. It is widely used in the solid-solid (powder material) and solid-liquid (powder material & fluidity material) mixing in the field of chemical industry, pharmacy, foodstuff industry, etc.

Horizontal Ribbon Mixer

consists of container, main shaft, and the drive transmission part. The container is U shape. The machine can be made of Carbon Steel (C model) and Stainless Steel (P model). It can be also

equipped with the jacket for the container

.

It can

heat, cool or vacuum

in the jacket.

The inside pressure of the jacket is less than 0.1 Mpa (The pressure can be customized).

Two layers screw ribbons makes the convection of the material to achieve the mixing effect rapidly.

Two layers screw ribbons makes the convection of the material to achieve the mixing effect rapidly.

There is a discharging valve in the middle of the container bottom. The drive parts adopt separated devices, that is, the motor is connected with reducer by the strap. Thus, It can save the space and has the overload protection.

Product details

1.Material

2.Motor

Options for motor:

general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor.

Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer. Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

3.Inlet

Various inlets on the top cover of the barrel can be designed according to different situations. They can be used as cleaning door, feeding hole, vent, and dust colleting hole. The top cover can be designed as fully-opened lid for easy cleaning.

4.Discharge port

The drive types of valve are

Manual, pneumatic and electric

. Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

5.Mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials. The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

Products Show

Application range

Technical Parameter

|

Model

|

Total Volume(L)

|

Load Coefficient

|

Power(KW)

|

Dimensions(mm)

|

Weight (kg)

|

|||||

|

DZRM-100

|

100

|

0.4-0.8

|

3

|

1190x740x770

|

330

|

|||||

|

DZRM-300

|

300

|

0.4-0.8

|

4

|

2030x630x980

|

720

|

|||||

|

DZRM-500

|

500

|

0.4-0.8

|

7.5

|

2320x730x1130

|

980

|

|||||

|

DZRM-1000

|

1000

|

0.4-0.8

|

11

|

2800x920x1320

|

1700

|

|||||

|

DZRM-1500

|

1500

|

0.4-0.8

|

11

|

3180x1020x1550

|

1800

|

|||||

|

DZRM-2000

|

2000

|

0.4-0.8

|

15

|

3310x1120x1640

|

2100

|

|||||

|

DZRM-3000

|

3000

|

0.4-0.8

|

18.5

|

3750x12290x1820

|

3000

|

|||||

|

DZRM-4000

|

4000

|

0.4-0.8

|

22

|

4220x1400x1990

|

3980

|

|||||

|

DZRM-5000

|

5000

|

0.4-0.8

|

22

|

4220x1500x2100

|

4620

|

|||||

|

|

|

|

|

|

||||||

Packing & Delivery

1. The inner packaging:stretch film; outer packaging:standard export fumigation-free wooden box

2. According to customer requirements

Hot Searches