- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/480V

-

Weight:

-

45Tons

-

Dimension(L*W*H):

-

13.5x2.2x2.6m

-

Certification:

-

SGS

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SINOMAC

-

Production Rate:

-

99%

-

Voltage:

-

220V/380V/480V

-

Weight:

-

45Tons

-

Dimension(L*W*H):

-

13.5x2.2x2.6m

-

Certification:

-

SGS

Cryogenic Liquid Oxygen Nitrogen Gas Air Separation Unit Generator

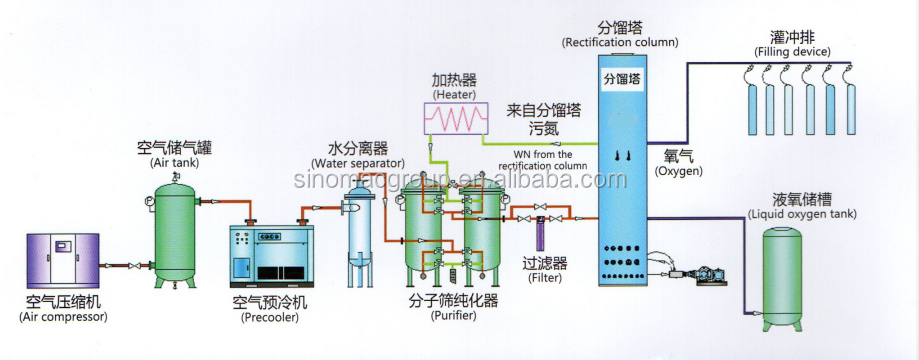

It uses mature cryogenic rectification technology. Our factory developed and designed a full-low pressure molecular sieve to purify the air and turboexpander refrigeration process to further reduce the energy consumption of small and medium sized air separation plants.

According to the compression style, it divide into:

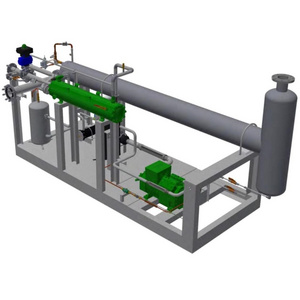

1. Internal Compression

The internal compression process is to cancel the oxygen compressor and directly replace it with a liquid oxygen pump and an air booster. The liquid oxygen is extracted from the main condensing evaporator of the air separation plant rectification tower, and the pressurized by the liquid oxygen pump to required pressure, and then a high pressure air exchanges heat with liquid oxygen to vaporize it out of the cold box as a products gas.

Air---Compression---Pre-cooler----Purifier---Rectification Exchange Heat---Liquid Oxygen Pump---Vaporizer---Oxygen Cylinder.

Internal Compression Features: 1. safe and economical 2. high automation control 3. small areas

|

Specification Model |

KZON-50/50 |

KZON- 80/80 |

KZON- 100/100 |

KDON 180/20 |

KDON300/50 |

KDON350/80 |

KDON500/150 |

KDON800/200 |

KDON 1000/300 |

|

O2 Flow (Nm3/h) |

50 |

80 |

100 |

180 |

300 |

350 |

500 |

800 |

1000 |

|

O2 Purity |

≥99.6% |

||||||||

|

N2 Flow (Nm3/h) |

50 |

80 |

100 |

20 |

50 |

80 |

150 |

200 |

300 |

|

N2 Purity |

≤10% |

||||||||

|

Operate Pressure |

1.2Mpa |

1Mpa |

|||||||

|

Start-up Time |

≤12 H |

≤10H |

≤8H |

||||||

|

Operate Period |

≥1Year |

≥2 Year |

|||||||

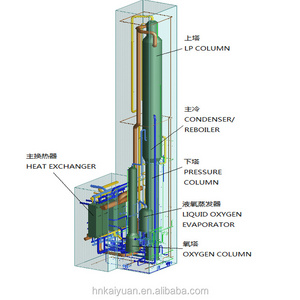

2. External Compression:

Its process directly produces low pressure oxygen from the rectification column, and then reheats the cold box through the main heat exchanger and then pressurizes it to the required pressure through the oxygen compressor to supply the user. Also called normal air separation.

Air---Compression---Pre-cooling---Purification---Rectification Heat Exchange---Oxygen Storage Tank---Oxygen Compressor---Oxygen Gas Cylinder

|

Model Specification |

K D ON- 8 0/ 200 |

K D ON- 1 80/ 50 0 |

K D ON- 35 0/ 8 00 |

KDON -350 / 90 0 |

KDON - 55 0/ 100 0 |

KDON - 7 50/ 150 0 |

KDON 10 00/ 200 0 |

KDON 15 00/ 30 00 |

KDON 3 000/ 30 0 0 |

|

O2Flow(Nm3/h) |

80 |

1 80 |

35 0 |

35 0 |

55 0 |

7 50 |

10 00 |

15 00 |

3 000 |

|

O2 Purity(%) |

≥99.6 |

||||||||

|

NFlow(Nm3/h) |

20 0 |

50 0 |

8 00 |

900 |

1000 |

1500 |

200 0 |

30 00 |

300 0 |

|

N2 Purity(%) |

≤10 %(ppm O2) |

||||||||

|

Operate Pressure |

0.65 |

0.63 |

0.62 |

0.62 |

0.6 |

0.58 |

0.58 |

0.56 |

0.56 |

|

Start-up Time (h) |

≤12 |

≤1 4 |

≤1 6 |

≤1 6 |

≤1 6 |

≤1 8 |

≤1 8 |

≤ 20 |

≤ 20 |

|

Operate Period (y) |

≥1 |

≥1 |

≥1 |

≥1 |

≥1 |

≥1 |

≥2 |

≥2 |

≥2 |

Welcome to visit our factory and air separation plant working site.