- Product Details

- {{item.text}}

Quick Details

-

Spindle Bore(mm):

-

65 m'm

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

250 mm

-

Travel (Z Axis)(mm):

-

750 mm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2500*1800*1800

-

Brand Name:

-

Lu Young

-

Model Number:

-

TCK56

-

Voltage:

-

380V

-

Weight (KG):

-

2600

-

Marketing Type:

-

New Product 2023

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Machine Type:

-

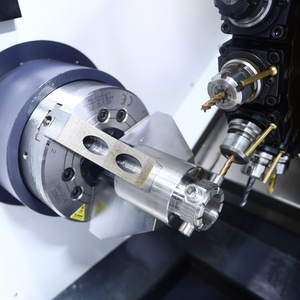

CNC Turning Center Machine TCK56 Slant Bed CNC lathe Machinery

-

Spindle bore:

-

56mm

-

Product type:

-

Economical CNC Lathe

-

Function:

-

Machining Metal

-

Precision:

-

National Standard

-

Spindle speed:

-

50-4500rpm

-

Max.swing over bed:

-

460mm

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

1500

-

Max. Spindle Speed (r.p.m):

-

4000 r.p.m

-

Spindle Bore(mm):

-

65 m'm

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

250 mm

-

Travel (Z Axis)(mm):

-

750 mm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2500*1800*1800

-

Brand Name:

-

Lu Young

-

Model Number:

-

TCK56

-

Voltage:

-

380V

-

Weight (KG):

-

2600

-

Marketing Type:

-

New Product 2023

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Machine Type:

-

CNC Turning Center Machine TCK56 Slant Bed CNC lathe Machinery

-

Spindle bore:

-

56mm

-

Product type:

-

Economical CNC Lathe

-

Function:

-

Machining Metal

-

Precision:

-

National Standard

-

Spindle speed:

-

50-4500rpm

-

Max.swing over bed:

-

460mm

TCK56 cheap mill combo live tooling metal cnc lathe machine price Slant Bed cnc lathe with c y axis and chip conveyor

Specification

|

parameter

|

TCK56

|

|

Max swing over bed Dia.( mm)

|

Φ560

|

|

Max swing over cross slide Dia.( mm)

|

Φ330

|

|

The distance between two centers( mm)

|

500/750

|

|

X axis travel( mm)

|

270

|

|

Z axis travel( mm)

|

500/750

|

|

X、Z axis feed speed(m/min)

|

30/36

|

|

X/Z axis feed motor powr(kw)

|

2.4

|

|

X/Z axis repeated positioning accuracy

|

0.005/0.006

|

|

X/Z-axis positioning accuracy( mm)

|

0.01/0.015

|

|

Spindle speed( rpm)

|

10-3000rpm

|

|

Spindle nose

|

A2-6

|

|

Spindle bore Dia( mm)

|

Φ66

|

|

Chuck

|

10” hydraulic chuck

|

|

Main motor(kw)

|

11/15KW

|

|

No.of tool holder

|

12 station

|

|

Y axis travel (mm)

|

90

|

|

Tool change time(s)

|

0.2

|

|

Tools size( mm)

|

25×25

|

|

Boring tool size( mm)

|

Φ32

|

|

Tailstock travel( mm)

|

440

|

|

taper of center

|

MT.NO.4

|

|

Coolant capacity(L)

|

150

|

|

L*W*H( mm)

|

2318*1585*1770

|

|

Machine weight(kg)

|

4500KG

|

Product Description

The

TCK56 cheap mill combo live tooling metal cnc lathe machine price Slant Bed cnc lathe with c y axis and chip conveyor

cnc bar automatic lathe product is a semi-closed slant-bed turning and milling

machine with X, Y, Z and C axes servo control. The structure and external dimensions are compact and reasonable. The spindle (C axis) is driven by a servo motor. It can realize the turning of the outer circle, the end surface and the thread of various materials, such as shafts and discs, and various surface milling and drilling in radial and axial directions, and is suitable for efficient machining of small parts.

machine with X, Y, Z and C axes servo control. The structure and external dimensions are compact and reasonable. The spindle (C axis) is driven by a servo motor. It can realize the turning of the outer circle, the end surface and the thread of various materials, such as shafts and discs, and various surface milling and drilling in radial and axial directions, and is suitable for efficient machining of small parts.

Product Feature

Standard configuration:

1) GSK980TB3 controller;

2) 8 stations electric tool post;

3) Linear guideways;

4) With manual tail stock;

5) 8'' manual chuck;

6) Cooling system;

7) Lighten system;

8) Automatic lubrication system;

Optional configuration:

1) CNC system: Siemens, Fanuc, etc.

2) Hydraulic chuck, hydraulic tailstock .

3) 8-station hydraulic turret;

4) Living tools

4 in end+4 in side

3 in end+3 in side

3 in end +2 in side

4 in end

3 in side

5)Automatic Chip conveyor;

1) GSK980TB3 controller;

2) 8 stations electric tool post;

3) Linear guideways;

4) With manual tail stock;

5) 8'' manual chuck;

6) Cooling system;

7) Lighten system;

8) Automatic lubrication system;

Optional configuration:

1) CNC system: Siemens, Fanuc, etc.

2) Hydraulic chuck, hydraulic tailstock .

3) 8-station hydraulic turret;

4) Living tools

4 in end+4 in side

3 in end+3 in side

3 in end +2 in side

4 in end

3 in side

5)Automatic Chip conveyor;

Hot Searches