- Product Details

- {{item.text}}

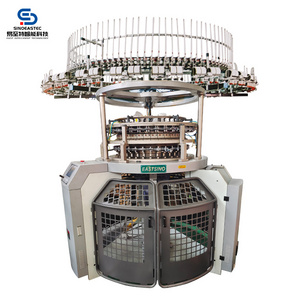

Quick Details

-

Gauge:

-

3 GG, 12 GG, 10GG, 3-5-7 multi-gauge

-

Knitting width:

-

80 inch

-

Place of Origin:

-

China

-

Power:

-

1200 W

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

700*800*700

-

Name:

-

Sweater Making Machine

-

Material:

-

Stainless Steel

-

Techinics:

-

Textile

-

Material Type:

-

Sweater

-

Quality:

-

China standard

-

Guarantee:

-

1 year(exclude the wearing parts)

-

Production time:

-

15 working days

-

Certification:

-

CE

Quick Details

-

Type:

-

Circular

-

Production Capacity:

-

200

-

Knitting Style:

-

Warp

-

Gauge:

-

3 GG, 12 GG, 10GG, 3-5-7 multi-gauge

-

Knitting width:

-

80 inch

-

Place of Origin:

-

China

-

Power:

-

1200 W

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

700*800*700

-

Name:

-

Sweater Making Machine

-

Material:

-

Stainless Steel

-

Techinics:

-

Textile

-

Material Type:

-

Sweater

-

Quality:

-

China standard

-

Guarantee:

-

1 year(exclude the wearing parts)

-

Production time:

-

15 working days

-

Certification:

-

CE

Specification

|

Model Name

|

Sweater Making Machine

|

|

|

|

Equipment Material

|

304 stainless steel

|

|

|

|

Pitch

|

3G-16G

|

|

|

|

Control System

|

Digital control

|

|

|

|

Number of needles/width

|

36/52/60/72/80 inches

|

|

|

|

Speed

|

1.2meters/seconds

|

|

|

|

Power

|

Voltage: AC 220V /380V Frequency: 50HZ/60HZ Power: 1.2KW

|

|

|

|

Dimension

|

800X700X900mm

|

|

|

|

Weight

|

800kg

|

|

|

1. Intelligent starting plate, the yarn is directly started from the bottom for weaving, which greatly saves the cost of waste

yarn. No need to remove stitches, saving workers time in removing stitches.

2. Intelligent yarn feeder, 16 sets of motors on both sides directly drive the yarn feeder, and the machine head and the yarn

feeder operate independently. It can realize the weaving of interchangeable plating fabrics, the multi-color intarsia weaving

styles are more abundant, and the weaving efficiency is obviously high.

3. Presser foot technology supports filling process and 5D three-dimensional relief effect weaving.

yarn. No need to remove stitches, saving workers time in removing stitches.

2. Intelligent yarn feeder, 16 sets of motors on both sides directly drive the yarn feeder, and the machine head and the yarn

feeder operate independently. It can realize the weaving of interchangeable plating fabrics, the multi-color intarsia weaving

styles are more abundant, and the weaving efficiency is obviously high.

3. Presser foot technology supports filling process and 5D three-dimensional relief effect weaving.

Product Description

Packing & Delivery

Hot Searches