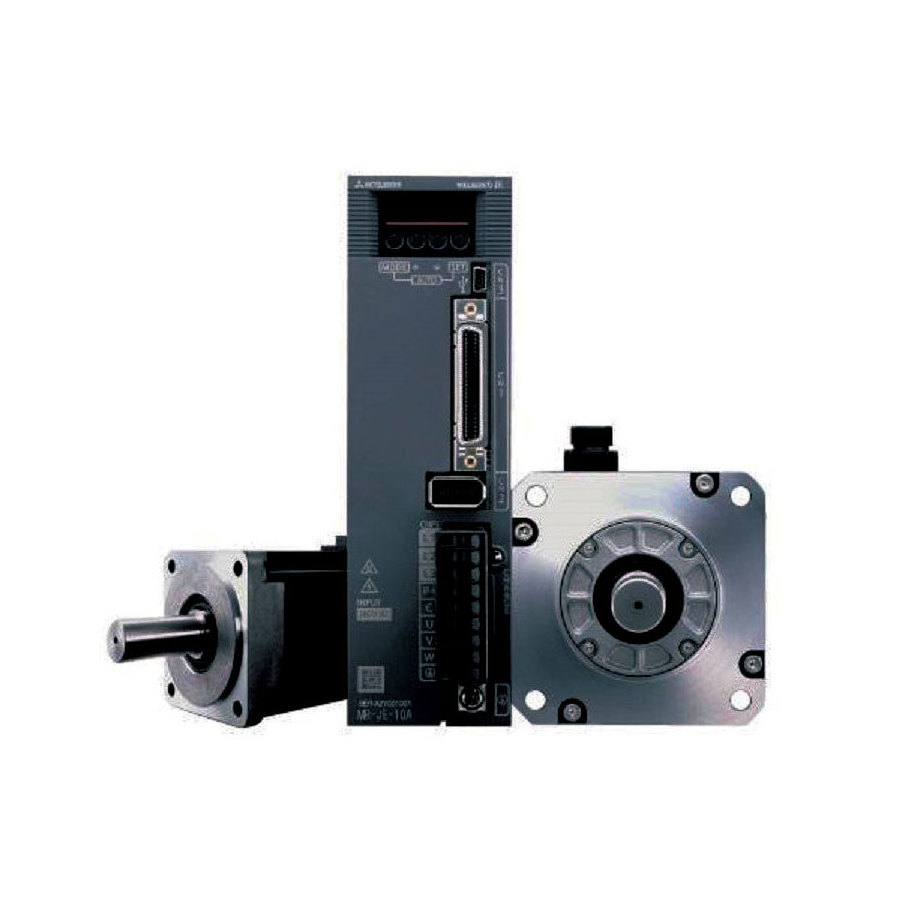

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MELSERVO-JET Series

-

Frequency:

-

2.5khz

-

Product name:

-

Servo motor

-

Application:

-

industrial automation

-

Item number:

-

MELSERVO-JET Series Servo Amplifiers

-

Rated speed (r/min):

-

3000

-

voltage specification:

-

AC200 specification

-

Resolution:

-

17 bit

-

Servo motor type:

-

low inertia

-

consists:

-

Controlled device Output sensor Feedback system

-

electromagnetic brake:

-

without

Quick Details

-

AC Voltage:

-

208-230 / 240 V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MITSU-BISHI

-

Model Number:

-

MELSERVO-JET Series

-

Frequency:

-

2.5khz

-

Product name:

-

Servo motor

-

Application:

-

industrial automation

-

Item number:

-

MELSERVO-JET Series Servo Amplifiers

-

Rated speed (r/min):

-

3000

-

voltage specification:

-

AC200 specification

-

Resolution:

-

17 bit

-

Servo motor type:

-

low inertia

-

consists:

-

Controlled device Output sensor Feedback system

-

electromagnetic brake:

-

without

Products Description

|

Product name

|

Servo motor

|

|

|

Application

|

industrial automation

|

|

|

Item number

|

MR-JET-10G MR-JET-20G MR-JET-40G MR-JET-70G MR-JET-100G MR-JET-200G MR-JET-300G

|

|

|

Type

|

Motor single

|

|

|

Rated speed (r/min)

|

3000

|

|

|

voltage specification

|

AC200 specification

|

|

|

Power

|

three-phase

|

|

|

Resolution

|

17 bit

|

|

|

Servo motor type

|

low inertia

|

|

|

consists

|

Controlled device Output sensor Feedback system

|

|

|

electromagnetic brake

|

without

|

|

|

Product Overview

|

MITSUBISHI JE series economic servo motor (HG-KN small capacity and small inertia series)

The MELSERVO-JE series of Mitsubishi Universal AC servo is an AC servo based on the MELSERVO-J4 series that limits the function while maintaining high performance. There are three control modes: position control, speed control and torque control. High speed pulse train up to 4 Mpps can be supported in position control mode. To select position/speed switching control, speed/torque switching control and torque/position switching control |

|

|

Product Features

|

Advanced one-button adjustment

Without computer, the servo adjustment can be completed by one-button operation In addition, the vibration suppression control and robust filter can be automatically adjusted. Increased transient stop tolerance Equipped with instantaneous stop TOUGH DRIVE function and large capacity main circuit capacitor Reduce downtime losses caused by transient stops Large capacity drive recorder The servo data before and after the alarm are stored in the non-volatile memory Quickly and accurately identify the cause of alarm Absolute position detection system MR-JE-B can use the servo motor encoder as an absolute position encoder Thus, the absolute position detection system is simply constructed |

|

|

Control mode selection of servo motor

|

Torque control

|

Torque control mode is to set the size of the output torque of the motor shaft through the input of external analog or direct

address assignment. Specifically, for example, if 10V corresponds to 5Nm, the output of the motor shaft is 2.5Nm when the external analog is set to 5V: if the motor shaft load is lower than 2.5Nm, the motor is rotating. The motor does not turn when the external load is equal to 2.5Nm, and inverts when the external load is greater than 2.5Nm (usually generated in the case of gravity load). It can change the set torque size by changing the setting of the analog quantity in real time, and also can change the value of the corresponding address by means of communication. It is mainly used in winding and unwinding devices that have strict requirements on the force of the material, such as wire raving devices or fiber pulling devices. The torque setting should be changed at any time according to the change of the winding radius to ensure that the force of the material will not change with the change of the winding radius. |

|

|

Position control

|

The position control mode is generally determined by the frequency of the external input pulse to determine the rotation speed,

the number of pulses to determine the Angle of rotation, and some servos can directly assign the speed and displacement through communication. Because the position mode can have a very strict control of both speed and position, it is generally applied to positioning devices. |

|

|

Speed Mode

|

The rotation speed can be controlled by the input of analog quantity or the frequency of pulse. The speed mode can also be

positioned when the outer loop PID control device is equipped with the upper control device, but the position signal of the motor or the position signal of the direct load must be given to the upper feedback for calculation. At this time, the encoder at the motor shaft end only detects the motor speed, and the position signal is provided by the direct detection device at the final load end. The advantage of this method is that the error in the intermediate transmission process can be reduced and the positioning accuracy of the whole system can be increased. |

|

|

Full closed-loop control mode: full closed-loop control is relative to semi-closed-loop control.

|

First let us understand the lower half closed loop control, half closed loop is the exponential control system or PLC to issue

speed pulse command. In the process of execution, the encoder of the servo itself feeds back the position to the servo, and the servo itself corrects the deviation. The error of the servo itself can be avoided, but the mechanical error cannot be avoided, because the control system does not know the actual position. Fully closed loop means that the servo receives the pulse command of controllable speed from the upper controller, and the servo receives the signal to execute. In the process of execution, there is a position feedback device on the mechanical device, which is directly fed back to the control system. The control system judges the deviation from the actual by comparison, and gives the servo instructions to correct the deviation. In this way, the control system completes the speed loop control of the servo through the frequency controllable pulse signal, and then completes the position loop control of the servo through the position sensor (grating scale, encoder). This control mode that combines the servo motor, motion controller and position sensor is called full closed-loop control. |

Shenzhen Muma Automation Techonology Co.,LTD.

We are a professional industrial 4.0 solution provider in Shenzhen, China. Focus on industrial automatic equipment provide and software combination. Our mission is making the modern industrial more intelligent, more efficiency. The mainly products including servo motor, servo motor driver, stepper close motor, gear-motor, vibration motor, brush-motor, brush-less motor, PLC (Programmable Logic Controller), HMI (Human-machine interaction), inverter much industrial automation equipment and all-in-one solution providing.

Hot Searches