- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

green sand mixer

-

Color:

-

As you want

-

Model:

-

Customized

-

Name:

-

Clay sand mixing machine

-

Application:

-

green sand mixing

-

Type:

-

Fully automatic

-

Brand:

-

Qingdao antai brand

-

Technology:

-

automatic

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

muller sand mixer

-

Brand Name:

-

Qingdao Antai

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

green sand mixer

-

Color:

-

As you want

-

Model:

-

Customized

-

Name:

-

Clay sand mixing machine

-

Application:

-

green sand mixing

-

Type:

-

Fully automatic

-

Brand:

-

Qingdao antai brand

-

Technology:

-

automatic

Products Description

I. Features

Green/Clay sand muller type sand mixer is a kind of sand mixer with high efficiency and new structure. The sand mixer adopts spring pressurization device, water adding device, collective lubrication, diabase stone protective plates these new materials and new structures, which plays an important role in ensuring molding sand quality, improving productivity and increasing service life.

This series of sand mixers have strong adaptability and wide application, and are widely used for mixing of molding sand in foundry workshop. Not only can it mix single sand, but also mix dry molding sand, self-hardening sand, surface sand and core sand.

It's also suitabe for mixing various powder and granular materials in glass, ceramics and refractory materials.

This series of sand mixers have strong adaptability and wide application, and are widely used for mixing of molding sand in foundry workshop. Not only can it mix single sand, but also mix dry molding sand, self-hardening sand, surface sand and core sand.

It's also suitabe for mixing various powder and granular materials in glass, ceramics and refractory materials.

II. Advantages

1. High sand mixing efficiency, good sand quality and wide application range.

2. New materials such as diabase cast stone, tungsten carbide surfacing, and No. 2 packing improve the life of wearing parts.

3. Hydraulic coupling, alloy steel gear, lubrication control machine, ensure the transmission system is stable and reliable, and can load start and overload protection.

4. Rotary discharge door is flexible and reliable.

5. Models with a diameter of ≥1600 mm are equipped with a steel chassis for ease of use and installation.

2. New materials such as diabase cast stone, tungsten carbide surfacing, and No. 2 packing improve the life of wearing parts.

3. Hydraulic coupling, alloy steel gear, lubrication control machine, ensure the transmission system is stable and reliable, and can load start and overload protection.

4. Rotary discharge door is flexible and reliable.

5. Models with a diameter of ≥1600 mm are equipped with a steel chassis for ease of use and installation.

III. Application

This series of sand mixers have strong adaptability and wide application, and are widely used for mixing of molding sand in foundary workshop. Not only can it mix single sand, but also mix dry molding sand, self-hardening sand, surface sand and core sand. It’s also suitable for mixing various powder and granular materials in glass, ceramics and refractory materials.

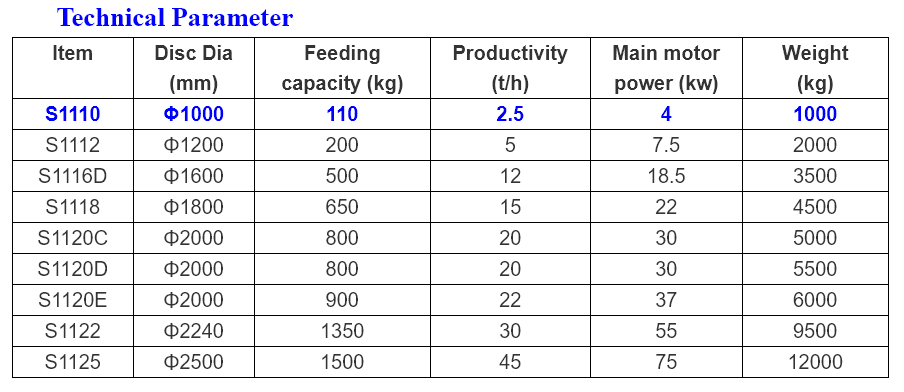

Technical Parameters

Details Images

Certifications

Hot Searches