After some time.

the adsorbed 02 reaches saturation, and the molecular sieve needs reactivation. The reactivation is realized bystopping adsorption step and decreasing pressure in adsorption tower, For saturated adsorption tower, after short time pressureequalzation, the pressure shall be decreased to remove adsorbed 02, H20, CO2, etc. and finish the reactivation process.

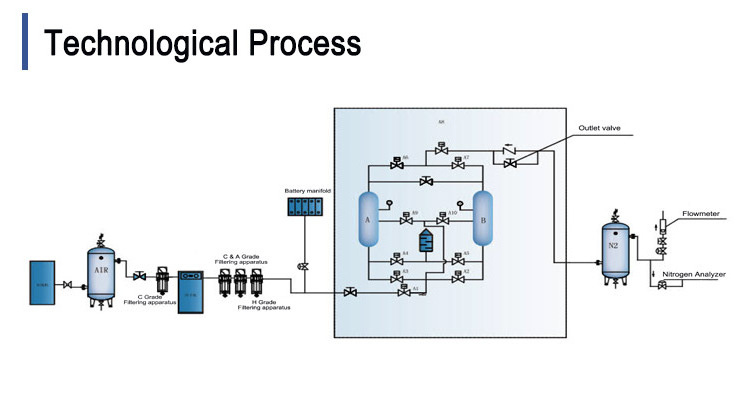

The two adsorption tower

shall shift for adsorption reactivation to produce gas nitrogen at stable flow and purity. The shift iscompleted by automatic control valves under PLC. The performance of PSA plant depends on absorber, carbon molecular

sievenrocass, equipments structure. and solenoid pneumatic valves. ec. Our PSA plant use PlC of Mitsubishi or Siemens. carbon molecular sieve of Takeda or first-dass CMS in China, solenoid pneumatic valve of Germany BURKET OR GEMU.