This machine can also be connected with production equipment.

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

1200bottle/min

-

Weight (KG):

-

2500

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DESSION

-

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weighing Range:

-

1~2000 g/time

-

Max. Weighing Quality:

-

6500g

-

Weighing Average Error:

-

0.1~1.5g

-

Weighing Speed:

-

360~1200 bottle/hour

-

Lid Feeding Form:

-

Raise the belt style cover

-

Capping Form:

-

Gripper cover to take the pneumatic screw cap

-

Capping Speed:

-

1200 bottle/hour

-

Labeling Position:

-

Bottle circumference surface

-

Applicable Labels:

-

Non-transparent label

-

Labeling Speed:

-

1500 bottle/hour

Quick Details

-

Function:

-

FILLING, Labeling, Capping, Sealing

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Plastic, Glass

-

Production Capacity:

-

1200bottle/min

-

Weight (KG):

-

2500

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DESSION

-

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weighing Range:

-

1~2000 g/time

-

Max. Weighing Quality:

-

6500g

-

Weighing Average Error:

-

0.1~1.5g

-

Weighing Speed:

-

360~1200 bottle/hour

-

Lid Feeding Form:

-

Raise the belt style cover

-

Capping Form:

-

Gripper cover to take the pneumatic screw cap

-

Capping Speed:

-

1200 bottle/hour

-

Labeling Position:

-

Bottle circumference surface

-

Applicable Labels:

-

Non-transparent label

-

Labeling Speed:

-

1500 bottle/hour

High Speed Weighing Filling Machine

Products Description

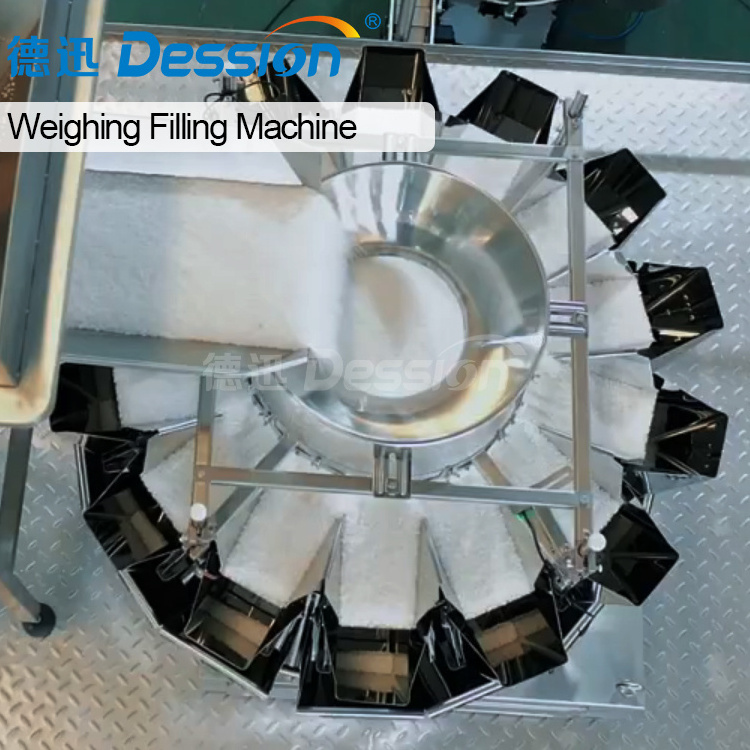

Automatic granule weighing filling machine is commonly used in the food, chemical, and pharmaceutical industries to increase efficiency and accuracy in the packaging process.

Dession automatic granule weighing filling machine is used to measure and dispense a precise amount of granular or powder products, such as sugar, salt, spices, detergent, or small grains. The machine can accurately measure the weight of the product and adjust the filling amount to ensure consistency in each packaging.

Machine Details

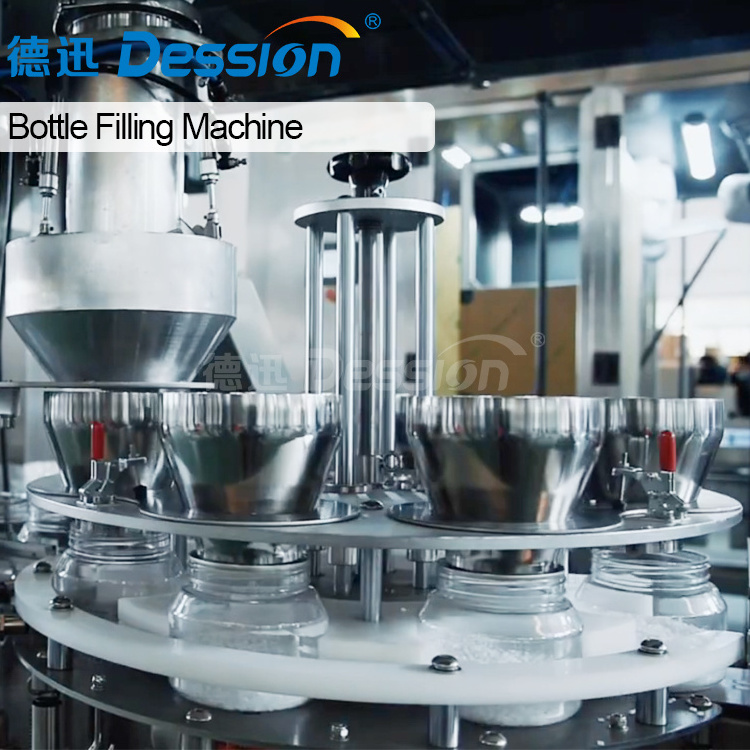

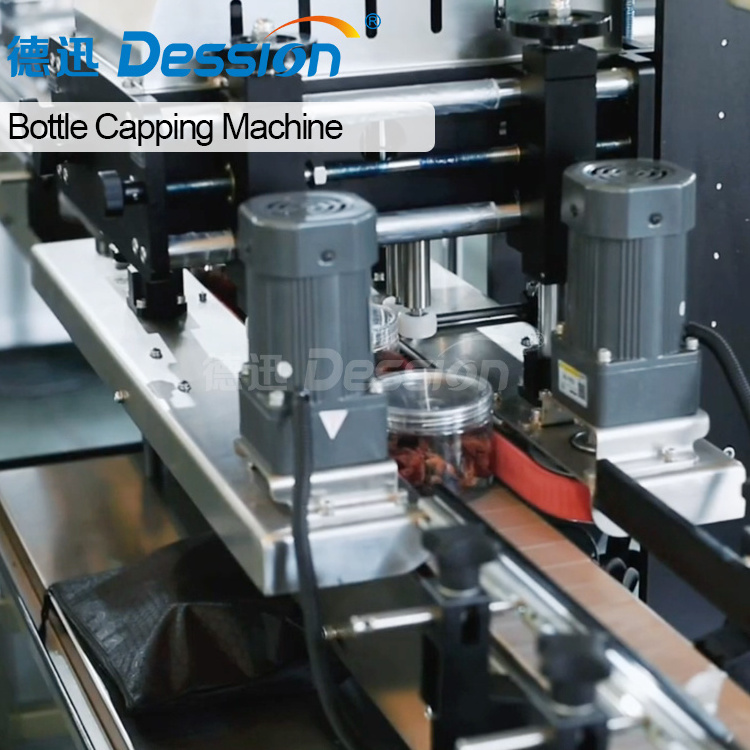

The machine first weighs the granules and then fills them into containers. After that, it screws on the caps and applies labels to the containers automatically.

The process is fully automated and requires minimal human intervention.

Z type feeder machine

Put the product into the machine hopper in advance, and the machine will automatically transport the product to the

hopper of the scale.

High precision weighing system

The granular product is fed into the hopper of the scale.

The weighing system uses load cells or other sensors to detect the weight of the product, and it can be programmed to stop the filling process when the target weight is reached.

Lid feeder machine

High speed capping machine

Bottle labeling machine

Once the bottle is capped, it is moved to the labeling station using a conveyor belt. The labeling machine applies the label to the bottle according to the customer's requirements, such as the product name, brand, and other information.

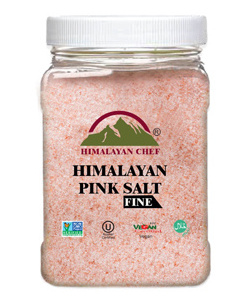

Packaging sample

Overall, an automatic granule weighing filling machine with a capping and labeling system is a highly efficient and accurate way to package granular products into bottles. It can help to increase productivity, reduce labor costs, and ensure consistency in the

packaging process.

packaging process.

Product Paramenters

The machine typically consists of a hopper for holding the granular product, a weighing system for measuring the weight of the product, a filling mechanism for dispensing the product into the container, and a conveyor belt to transport the container. The weighing system can use load cells or other sensors to detect the weight of the product, and it can be programmed to stop the filling process when the target weight is reached.

It can also be integrated with other equipment, such as capping machines and labeling machines, to provide a complete packaging solution.

Machine Characteristics

1. Optical and mechanical integration of a high degree of intelligence, mechanical, photoelectric double intelligent sensor technology, with or without color can be.

2. With no bottle does not work, fault selt-tes.

3. Alarm control function to ensure continuity and accuracy.

4.Fully automatic operation, and no the next road a process of intelligent control, good coordination, no need to operatem save labor.

5. Compact structure, no need to frequently replace the accessories, small footprint, low cost, cost-effective, economical and practical.

|

Weighing Range

|

1~2000 g/time

|

|

Max. Weighing Quality

|

6500g

|

|

Average Error

|

0.1~1.5g

|

|

Weighing Speed

|

360~1200 bottle/hour

|

|

Hooper Capacity

|

2500ml

|

|

Lid Feeding Form

|

Raise the belt style cover

|

|

Capping Form

|

Gripper cover to take the pneumatic screw cap

|

|

Capping Speed

|

1200 bottle/hour

|

|

Air Pressure

|

0.6~0.8 Mpa

|

|

Labeling Position

|

Bottle circumference surface

|

|

Applicable Labels

|

Non-transparent label

|

|

Labeling Speed

|

1500 bottle/hour

|

|

Error Range

|

±1 mm

|

|

Air Pressure

|

0.6~0.8 Mpa

|

The use of high-quality imported components is one of the key reasons behind the machine's stability and superior performance. The electrical configuration of the machine incorporates parts from leading brands such as Siemens from Germany, AIRTAC from Taiwan, SMC from Japan, SICK from Germany, Matsushita from Japan, and Schneider from France.

These companies are renowned for their expertise and innovation in the field of electrical engineering, and their components are known for their durability, precision, and reliability. By using these premium components, the machine is able to deliver consistent, high-quality performance over an extended period of time, making it a reliable investment for businesses seeking to enhance their production efficiency and output.

|

Machine Electrical Configuration

|

|

|

|

Program Controller

|

Siemens, Germany

|

|

|

Touch Screen

|

Siemens, Germany

|

|

|

Pneumatic Components

|

AIRTAC Taiwan, SMC Japan

|

|

|

Photoelectric Sensor

|

LEUZE Germany, SICK Germany, Panasonic Japan

|

|

|

The beginning of relay and air

|

Schneider French, Shenle, Delixi China

|

|

|

Motor Inverter

|

Siemens Germany

|

|

Why Choose Us

1. Strong factory strength

Dession Machinery is a modern packaging equipment solution provider integrating R&D, production and sales. Since the establishment of the company, with the continuous exploration, research and application of advanced technology.

The company has been developing for more than 10 years and has a team composed of professional technicians, engineers, sales and after-sales service personnel.

We have developed many series of packaging machinery and related supporting equipment, which are widely used in food, hotel supplies, daily necessities, hardware accessories and other product packaging industries.

All equipment has CE, ROHS certificates, quality inspection reports, etc. to ensure the quality of the equipment. Choose us, choose success.

We have developed many series of packaging machinery and related supporting equipment, which are widely used in food, hotel supplies, daily necessities, hardware accessories and other product packaging industries.

All equipment has CE, ROHS certificates, quality inspection reports, etc. to ensure the quality of the equipment. Choose us, choose success.

2. Professional after-sales service team

We provide complete machine installation and commissioning manuals and videos to ensure that the machine can be used as soon as you receive it.Professional after-sales engineers escort customers, and the machine is guaranteed for life.

When customers encounter problems during use, we will reply and provide solutions within 24 hours.

Customer Praise

Years of foreign trade experience has allowed us to gain recognition and praise from customers all over the world.

Since the establishment of the company, we have traded in more than 100+ countries, especially the European and American markets, which have been well received.

FAQ

Q1:Do you have manual or operation video for us to know more about the machine?

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Hot Searches