- Product Details

- {{item.text}}

Quick Details

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Function:

-

Cutting, Marking, Punching

-

Cutting thickness:

-

1-100mm

-

Format Supported:

-

DXF, PLT

-

Working Area:

-

1600mmX2500mm

-

Cutting Accuracy:

-

≤0.1mm

-

Voltage:

-

220V 380V±10%,50HZ

-

Fixed Mode:

-

Vacuum Suction Table

-

Pump power:

-

7.5KW/9KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMOR

-

Weight (KG):

-

1380

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Function:

-

Cutting, Marking, Punching

-

Cutting thickness:

-

1-100mm

-

Format Supported:

-

DXF, PLT

-

Working Area:

-

1600mmX2500mm

-

Cutting Accuracy:

-

≤0.1mm

-

Voltage:

-

220V 380V±10%,50HZ

-

Fixed Mode:

-

Vacuum Suction Table

-

Pump power:

-

7.5KW/9KW

Products Description

Product Paramenters

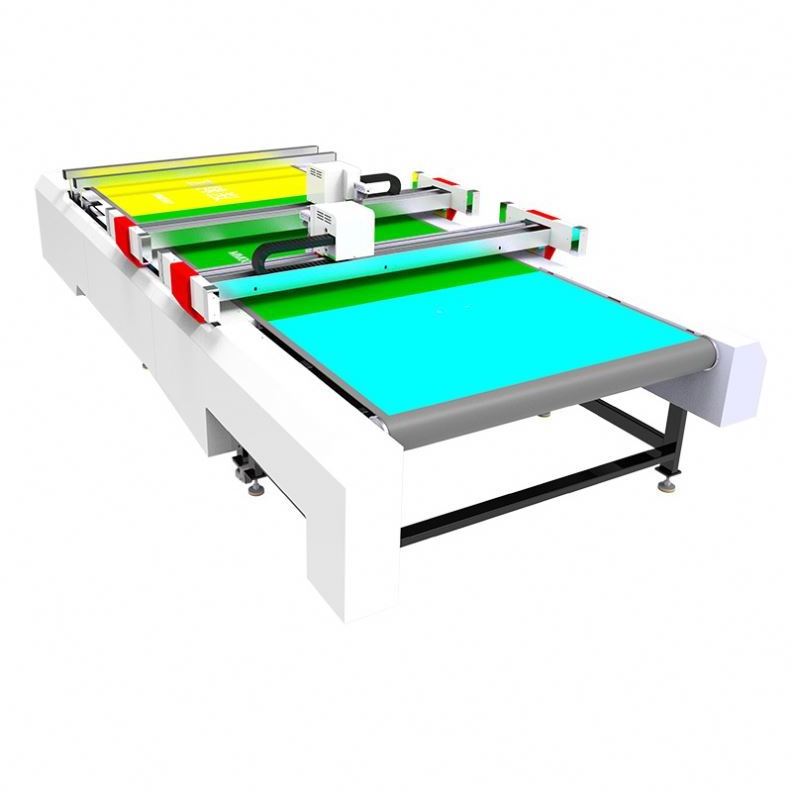

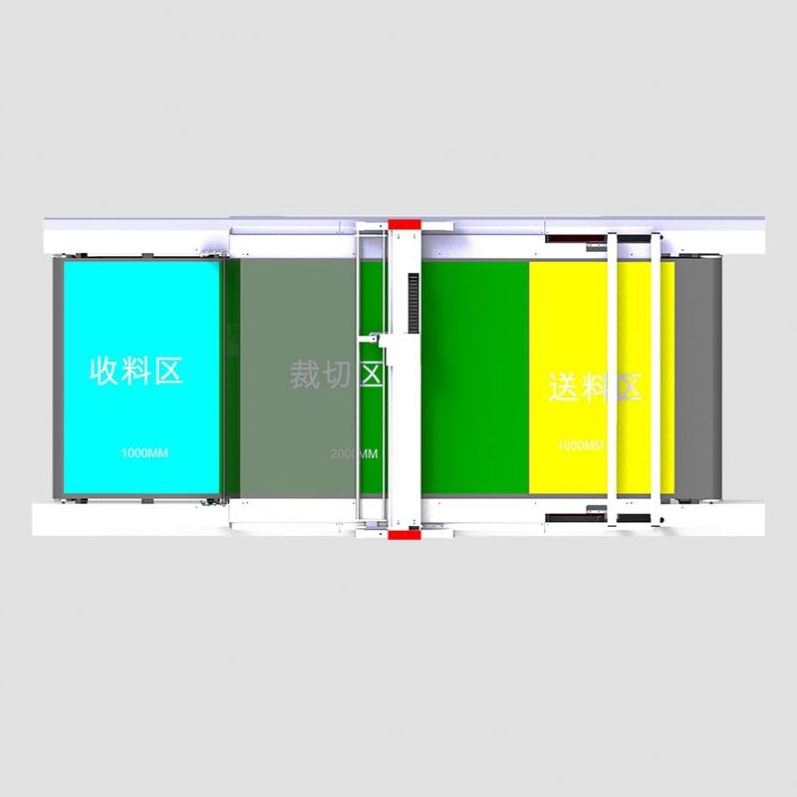

AMORFull Automatic Ultrasonic Textile Roller Blinds Non Woven Fabric Cutting Table

|

Model

|

AMOR-1625AK

|

AMOR-2125AK

|

AMOR-2030AK

|

Customize

|

|||

|

Working Area

|

1600*2500mm

|

2100*2500mm

|

2000*3000mm

|

|

|||

|

Applicable Materials

|

It can be used to continuously cut various fabric rolls, such as: upholstered sofa fabric, textile, leather, neoprene fabric, PU leather, PVC coated fabric, etc.

|

|

|

|

|||

|

Drive Motor

|

Japan’s Mitsubishi Servo Motor and Drive

|

|

|

|

|||

|

Machine Advantage

|

1.The X axis is driven by double Japanese Mitsubishi servo motors;

2.The measurement adopts 7mm aviation aluminum alloy material, and

the mold is extruded;

3.All electrical accessories use the French Schneider brand.

|

|

|

|

|||

|

Cutting Thickness

|

0.1-45.0mm according to materials(Customizable maximum cutting thickness 110mm)

|

|

|

|

|||

|

Cutting Speed

|

1500mm/s

|

|

|

|

|||

|

Cutting tolerance

|

±0.1mm

|

|

|

|

|||

|

File Format

|

DXF, PLT

|

|

|

|

|||

|

Fixed Mode

|

Vacuum Partittion Adsorption

|

|

|

|

|||

|

Safety Devices

|

Use infrared sensing, safe and reliable

|

|

|

|

|||

|

Total Power

|

11KW (Vacuum pump power 9KW)

|

|

|

|

|||

|

Input Voltage

|

AC 220V 380V±10%,50HZ(Configurable transformer for customer location)

|

|

|

|

|||

|

Recommended Tools

|

High-power POT, 400W high-power EOT, high-speed milling cutter

|

|

|

|

|||

Applications

AMOR CNC fabric cutting machines offer intelligent, precise, and efficient solutions for cutting sofa fabrics, revolutionizing upholstery manufacturing. Their advanced technological features ensure that they can meet the demands of modern sofa production, providing manufacturers with the tools necessary to create high-quality products while optimizing material use and reducing production times.

1. Advanced Digital Interface and Software Integration

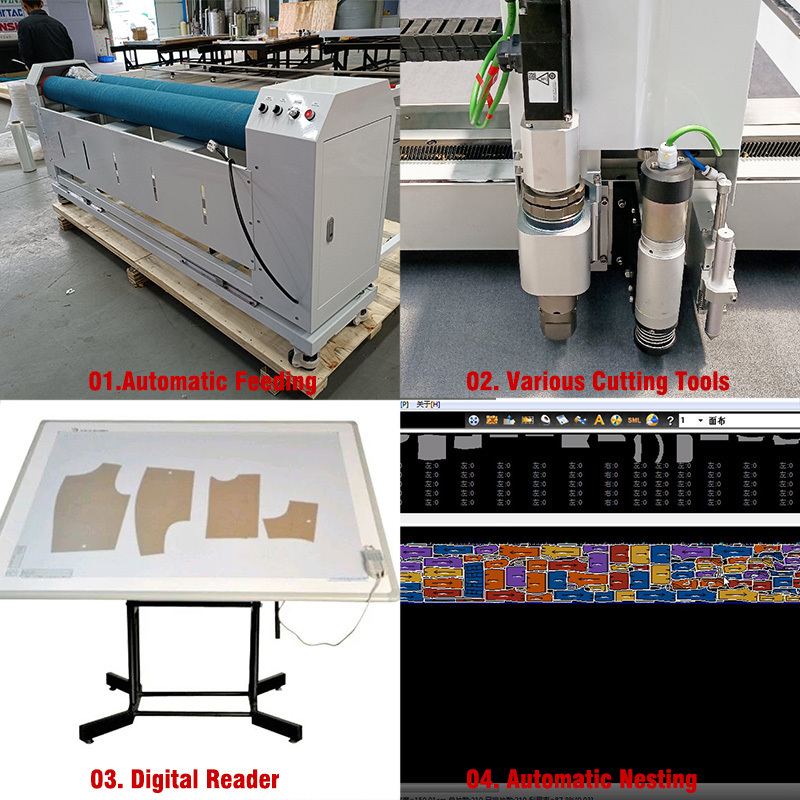

Digital Image Reading System

:

AMOR CNC machines are equipped with advanced digital image reading system can quickly and accurately convert paper templates into electronic data (DXF, PLT). This software can handle complex patterns and multiple fabric layers, translating detailed designs into precise cutting instructions.

Automated Nesting Software:

The software optimizes the layout of the cutting patterns on the fabric to maximize material utilization and minimize waste. This is particularly important when working with expensive materials like leather or designer fabrics.

02. Efficient and Rapid Production

High-Speed Cutting:

AMOR CNC machines are designed for high-efficiency and rapid production. The cutting speed can be adjusted based on the fabric type and the complexity of the cut, allowing for quick turnaround times without compromising on the quality of the cuts.

Continuous Cutting Operations:

These machines can operate continuously over extended periods, which is essential for meeting high production demands in commercial sofa manufacturing. Automation reduces the need for manual intervention, enabling non-stop production with consistent results.

Recommended Tools

The cutting is performed using a high-speed oscillating knife, which is ideal for cutting multiple layers of fabric or dense materials without fraying or inaccuracies. The oscillating motion allows the knife to cut cleanly through the material, maintaining the integrity of the fabric edges.

Depending on the type and thickness of the material, different cutting tools or blades can be attached to the machine. AMOR machines often come with a range of interchangeable tools that can quickly be swapped to handle different materials like leather, thick upholstery fabrics, or delicate textiles.

Pneumatic oscillating tools

Using 0.7MPA compressed air, it can be used to cut 8-25 layers of fabric or leather.

Punching Pool

It can be used for fast punching notches, and can be configured with punches of different diameters such as 3mm and 5mm.

Marking Tool

Marking pen or inkjet system can be configured to mark information on parts.

Why Choose Us

AMOR CNC fabric cutting machines represent a significant advancement in the field of upholstery and soft furniture manufacturing, particularly in the cutting of sofa fabrics. These machines integrate state-of-the-art technology to automate and optimize the cutting process, ensuring high efficiency, precision, and material utilization.

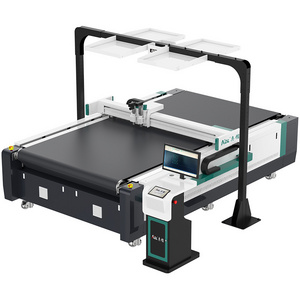

Honeycomb Adsorption Platform

The thickness is 42.5mm, made of aviation aluminum alloy, with good flatness and a height error of 0.2mm.

Strong Power

The X-axis adopts the transmission mode of 2X400 Mitsubishi servo motor + precision reducer, which is powerful and high-precision.

Good Electrical Components

All electrical components are from international brands such as French Schneider, Japanese Omron, and American 3M.

Auto Feeding System

It comes with a feeding correction system to ensure continuous and accurate transportation of rolled fabrics.

Automatic Nesting Software

Equipped with an advanced automatic nesting system, it realizes intelligent management of sofa pieces. It only takes 30 seconds to complete the nesting of the entire sofa, saving 10%.

Crawler Feeding Platform

The crawler-type feeding platform is used to realize automatic conveying and cutting of rolled fabrics. In theory, the processing length can be infinite, and only one person can complete all operations of the machine.

Heavy Welded Bed

Reinforcing ribs are arranged inside the bed to increase the strength and tensile resistance of the bed, and effectively avoid deformation of the bed.

Aluminum Alloy Die Extrusion Beam

The wall thickness is 8mm and the width is 220mm. It has its own installation reference and has strong anti-deformation ability.

Vacuum Adsorption System

Supports multiple partition adsorption modes: according to graphics, cutting position and manual settings, etc. Hold the material firmly.

Hot Searches