- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TONY

-

Dimension(L*W*H):

-

2500*1600*2400

-

Motor Power (Kw):

-

160

-

Weight (KG):

-

9500 KG

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Wood Pellet Machine Making

-

Pellet size:

-

6-10mm Diameter

-

Application:

-

Make Biomass Pellets

-

Color:

-

Customer's Request

-

Capacity:

-

2-3.5T/h

-

Service:

-

Provide After-sale Service

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

Quick Details

-

Pellet Diameter (mm):

-

6 - 8

-

Output (kg/h):

-

2500 - 3000 kg/h

-

Place of Origin:

-

ShanDong,China

-

Brand Name:

-

TONY

-

Dimension(L*W*H):

-

2500*1600*2400

-

Motor Power (Kw):

-

160

-

Weight (KG):

-

9500 KG

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Keywords:

-

Wood Pellet Machine Making

-

Pellet size:

-

6-10mm Diameter

-

Application:

-

Make Biomass Pellets

-

Color:

-

Customer's Request

-

Capacity:

-

2-3.5T/h

-

Service:

-

Provide After-sale Service

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

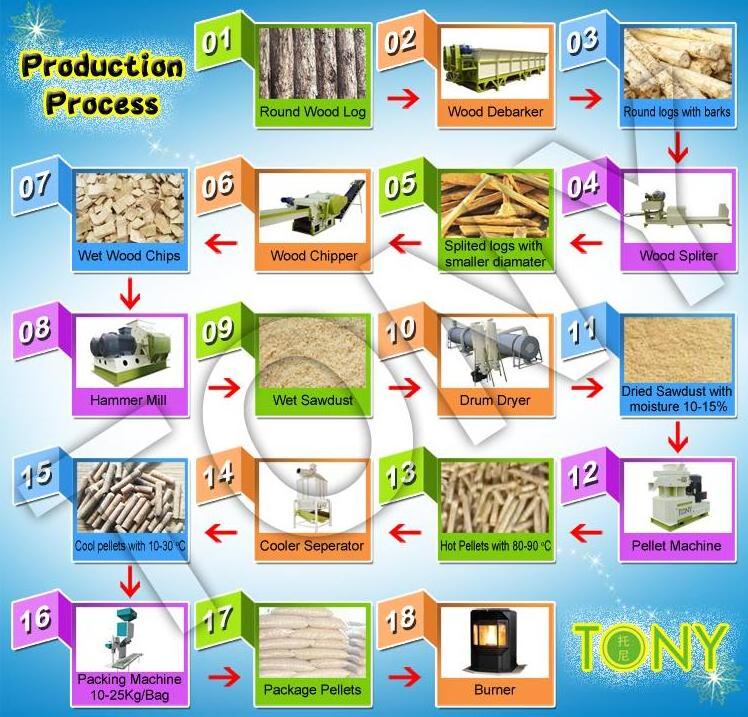

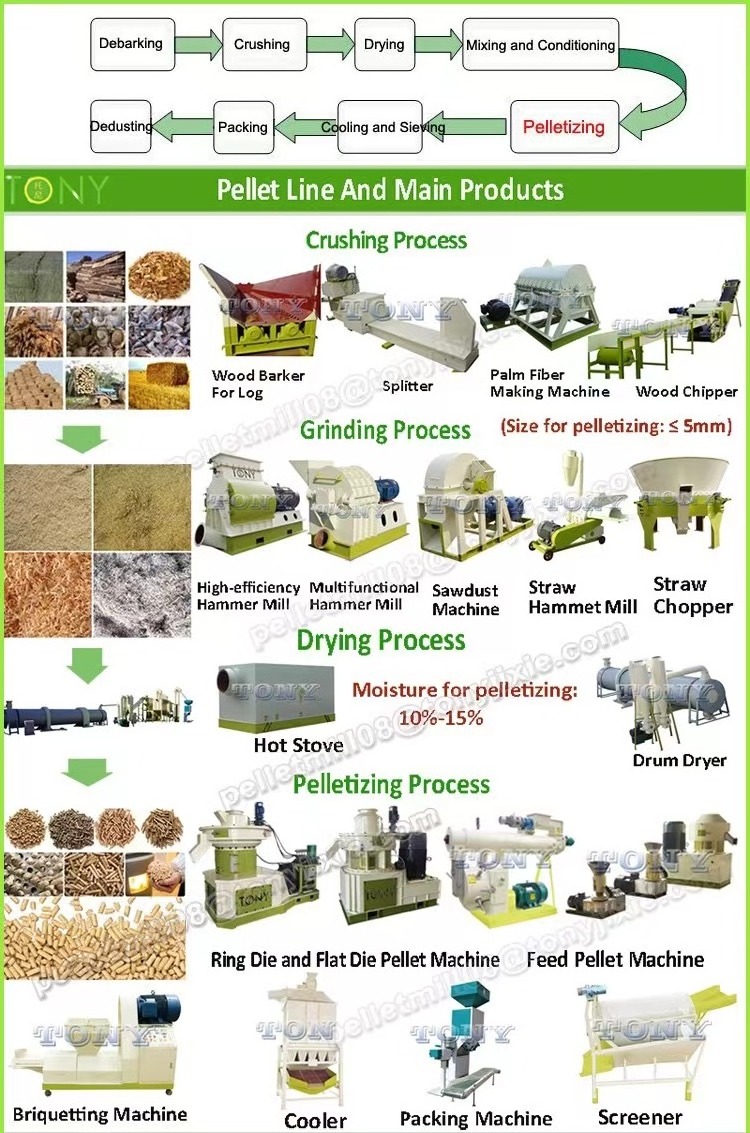

Biomass pellet line is a new protection energy equipment.Its main equipments are wood debarker-optional, log spliter-ptional,wood chipper,high effective hammer mill/mutifuntional hammer mill,hot stove,rotary drum dryer,biomass vertical ring die pellet machine,cooler seperator,packing machine,15-50kg/bag/ton packing machine and belt conveyor or other necessary equipments for the whole pellet line.

|

Requirements for raw materials

|

|

|

Less than 5 mm

|

|

|

Moisture

|

10-15% (Due to your raw materials)

|

|

Finished Pellets

|

Diameter: 4mm, 6mm, 8mm, 10mm, 12mm

|

productive process

| Production line machine display |

Drum Wood Chipper: Wood chipper can turn diamater under 50cm logs,trail wood ,etc into excellet industrial wood chip which is uniform in length,flat in cut uniform in thickness .Raw material can be small diamater wood,wood harvesting residuse and wood processing surplus.Can also be used to cut non-wood raw materals.

High-Efficient Hammer Mill: High efficiency crusher is specially used for biomass fuel production, early material grinding. Can crush wood chips, shavings, grain and plant fiber, feed processing fine powder and so on.

Rotary Drum Dryer: Using low speed rotation, bending plate hammer, disperse materials, so that high temperature air and material mix, to achieve uniform drying effect

Biomass pellet machine: A biomass pellet machine compacts sawdust into pellets

Cooling Process: After the pelletizing process, the temperature of the wood pellet is about 60-80 degree, and the moisture content of the wood pellet is about 14%, so we need use Cooler to reduce about 3-4% moisture, such this the wood pellet is easy to store.

But considering the feedback from some foreign clients, the local climate is very humidity; they hope to cool the wood pellet with moisture 7-8%. In order to satisfy the different need from different clients, we develop one kind of new Stabilizer Combined Cooler.

Packing Process: After cooling, the wood pellet will not directly enter into the fuel process, avoiding the wood pellet affected with damp. The packing process is necessary. In this process, we assemble our domestic best Semi-Auto Packing Machine to you.

|

Packaging and shipping |

| Our engineers avaliable to service abroad. |

|

Successful Overseas Experiences

-----Our pellet line have been exprted to many countries, such as Australia, Serbia, Thailand, Vietnam, Malaysia, India, Singapore, Bulgaria, Indonesia, etc.

|

| authentication certificate |

manufacturer recognized by General Administration of Quality Supervision, Inspection and Quarantine for over 15 years. Located in Jinan East Intelligent Manufacturing New City,Zhangqiu,Jinan City,Shandong Province,China

24 Hours Online Service.

-Inquiry will be replied within 2 hours.

-All-the-way tracking service offered from placing order to delivery.

-Free training for operation, debugging and daily maintenance.

-We can provide professional guide installation.

-One year warranty and all-round after-sales service.

-Customized design and flow chart are available for our clients.

-Independent R&D team and strict & scientific management system.

If you're interested in our complete pellet production line , pls kindly tell us the following information:

1. What's the capacity you want?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content?

5. What's the final pellet size do you want?

6. Automatic packing or manual packing needed?

7. What's your country voltage?

Email: pelletmill02 @ tonyjixie.com