- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

Air Cooling

-

Control Software:

-

EZCAD

-

Weight (KG):

-

60 KG

-

Laser wavelength:

-

355nm

-

Frequency:

-

20-80KHZ

-

Min line width:

-

0.01mm

-

Power:

-

3W/5W/10W/15W

-

Cooling method:

-

Air cooling/Water cooling

-

Marking range:

-

110*110mm(standard), 150*150mm, 200*200mm, 300*300mm(optional)

-

Power consumption:

-

0.5KW-1.5KW

-

File format:

-

All formats

Quick Details

-

Working Accuracy:

-

0.001mm

-

Graphic Format Supported:

-

AI, BMP, Dst, Dwg, DXF, DXP, PLT

-

Laser Type:

-

UV

-

Cooling Mode:

-

Air Cooling

-

Control Software:

-

EZCAD

-

Weight (KG):

-

60 KG

-

Laser wavelength:

-

355nm

-

Frequency:

-

20-80KHZ

-

Min line width:

-

0.01mm

-

Power:

-

3W/5W/10W/15W

-

Cooling method:

-

Air cooling/Water cooling

-

Marking range:

-

110*110mm(standard), 150*150mm, 200*200mm, 300*300mm(optional)

-

Power consumption:

-

0.5KW-1.5KW

-

File format:

-

All formats

Product Description

Application:

Widely used for superfine marking, engraving, cutting.It is especially suitable for applications such as marking of food and pharmaceutical packaging materials, micropores, high-speed division of glass materials, wood materials and complex graphic cutting of wafer wafers.

Main Features

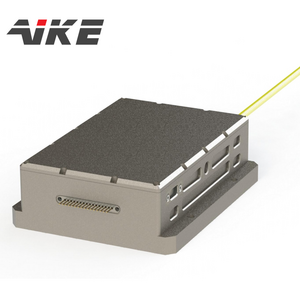

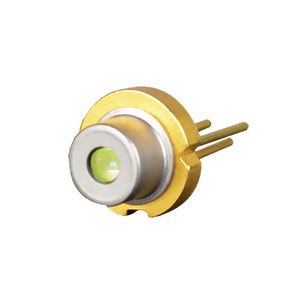

* Laser (light source): 355nm UV laser

* 3W uv laser is with air-cooling system, small size, theoretically20,000 hours service life.

* It requires water cooling for bigger power uv laser machines, put distilled water or pure water into the chiller.

* The focused spot is extremely small, and the processing heat affected zone is small (cold light), making the material

heat-receiving area smaller. Not susceptible to heat deformation, ultra-fine marking, special material marking.

* Low cost of use, better beam quality, high efficiency, low power consumption, more energy saving and environmental protection.

* Can be applied to high-end market, ultra-fine marking environment, cosmetics, pharmaceuticals, LCD liquid crystal, electronic components, communication equipment, food and medicine packaging, glass division, electronic components, metal jewelry marking.

Widely used for superfine marking, engraving, cutting.It is especially suitable for applications such as marking of food and pharmaceutical packaging materials, micropores, high-speed division of glass materials, wood materials and complex graphic cutting of wafer wafers.

Main Features

* Laser (light source): 355nm UV laser

* 3W uv laser is with air-cooling system, small size, theoretically20,000 hours service life.

* It requires water cooling for bigger power uv laser machines, put distilled water or pure water into the chiller.

* The focused spot is extremely small, and the processing heat affected zone is small (cold light), making the material

heat-receiving area smaller. Not susceptible to heat deformation, ultra-fine marking, special material marking.

* Low cost of use, better beam quality, high efficiency, low power consumption, more energy saving and environmental protection.

* Can be applied to high-end market, ultra-fine marking environment, cosmetics, pharmaceuticals, LCD liquid crystal, electronic components, communication equipment, food and medicine packaging, glass division, electronic components, metal jewelry marking.

Product packaging

Specification

FAQ

1. What is UV laser marking machine?

The high absorption rate of laser ultraviolet (UV) markers, which is well known, enables them to mark a range of materials,

particularly on plastics and organic materials, with little heat damage and outstanding contrast.

Principle:The principle of the UV laser marking machine is similar to that of the laser marking machine in that it uses laser beams to permanently mark the surface of a range of different materials. In order to show the desired etched pattern or text, the effect of marking is to immediately break the molecular chain of the material using a short wavelength laser (as opposed to a long wavelength laser created by evaporating the surface material to reveal the deep material).

2. What is the difference between UV Laser and Fiber Laser?

These machines are designed for different material engraving solutions

The main use of fiber laser engraving machines is engraving and providing solutions for the metal marking industry. The machines can mark, engrave (see the difference between engraving and marking) and engrave on all metal materials. In addition, the UV laser is designed as a practical solution for marking plastics and glass – the UV laser machine can engrave a large range of materials, from metal to paper.

3.What are the advantages of UV laser machines?

The main advantage of UV laser technology is the versatility and ability to engrave on different materials, including non-metallic materials. The technology can also be used with automated systems such as rotary engraving, linear guide engraving, conveyor belt engraving systems and camera capture systems.

4. Factors that influence your choice of UV laser machine?

In addition to the type of laser machine, there are other important factors that can help you choose the best UV laser machine. The kind of material you want to mark : The kind of material you want to mark greatly influences the laser machine you choose. As was already noted, various UV laser machines have different surfaces that they perform best on.

Budget : If you have a small budget, then you can choose a simple and basic UV laser machine that will help you with the basic taskof marking your products. Size of your business : Choosing a UV laser machine is heavily influenced by the size of your business. A more sophisticated equipment can be required if your business is big and you need to label lots of items quickly.

5. How long is the delivery time?

For standard machines, it would be 5-7 days; For non-standard machines and customized machines according to client's specific requirements, it would be 15 to 30 days.

The high absorption rate of laser ultraviolet (UV) markers, which is well known, enables them to mark a range of materials,

particularly on plastics and organic materials, with little heat damage and outstanding contrast.

Principle:The principle of the UV laser marking machine is similar to that of the laser marking machine in that it uses laser beams to permanently mark the surface of a range of different materials. In order to show the desired etched pattern or text, the effect of marking is to immediately break the molecular chain of the material using a short wavelength laser (as opposed to a long wavelength laser created by evaporating the surface material to reveal the deep material).

2. What is the difference between UV Laser and Fiber Laser?

These machines are designed for different material engraving solutions

The main use of fiber laser engraving machines is engraving and providing solutions for the metal marking industry. The machines can mark, engrave (see the difference between engraving and marking) and engrave on all metal materials. In addition, the UV laser is designed as a practical solution for marking plastics and glass – the UV laser machine can engrave a large range of materials, from metal to paper.

3.What are the advantages of UV laser machines?

The main advantage of UV laser technology is the versatility and ability to engrave on different materials, including non-metallic materials. The technology can also be used with automated systems such as rotary engraving, linear guide engraving, conveyor belt engraving systems and camera capture systems.

4. Factors that influence your choice of UV laser machine?

In addition to the type of laser machine, there are other important factors that can help you choose the best UV laser machine. The kind of material you want to mark : The kind of material you want to mark greatly influences the laser machine you choose. As was already noted, various UV laser machines have different surfaces that they perform best on.

Budget : If you have a small budget, then you can choose a simple and basic UV laser machine that will help you with the basic taskof marking your products. Size of your business : Choosing a UV laser machine is heavily influenced by the size of your business. A more sophisticated equipment can be required if your business is big and you need to label lots of items quickly.

5. How long is the delivery time?

For standard machines, it would be 5-7 days; For non-standard machines and customized machines according to client's specific requirements, it would be 15 to 30 days.

6.This is the first time I buy this kind of machine, is it easy to operate?

We will send you manual and guide videos in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Team viewer" online help software.Or we can talk by phone, email or other contact ways.We always offer good customer services in order to corporate with you in a longer term.

Hot Searches