- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3*380V

-

Dimension(L*W*H):

-

4060*2100*2950mm

-

Weight (T):

-

15 T

-

Power (kW):

-

10

-

Application:

-

Melting Metal

-

Product Name:

-

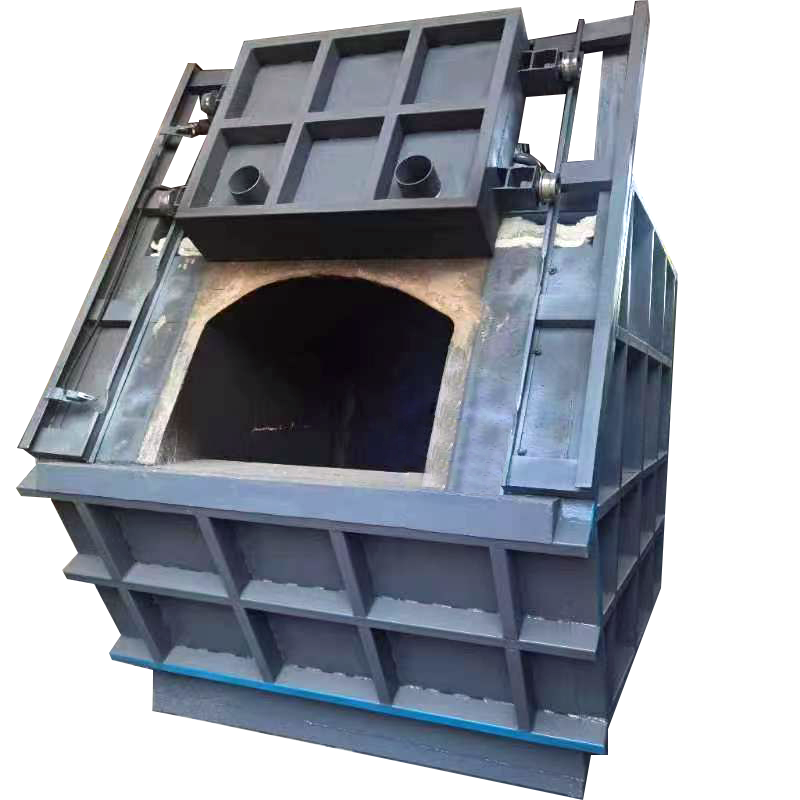

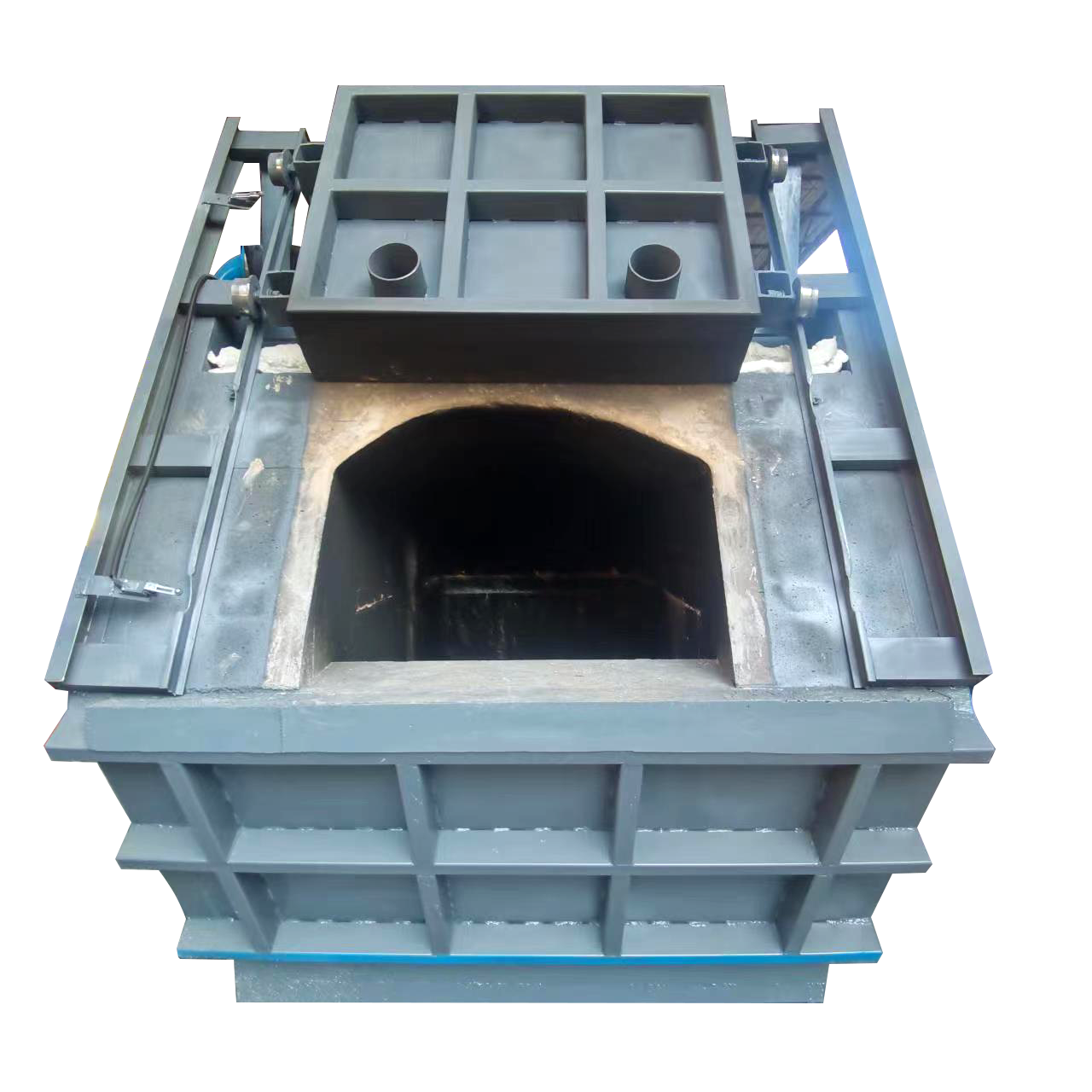

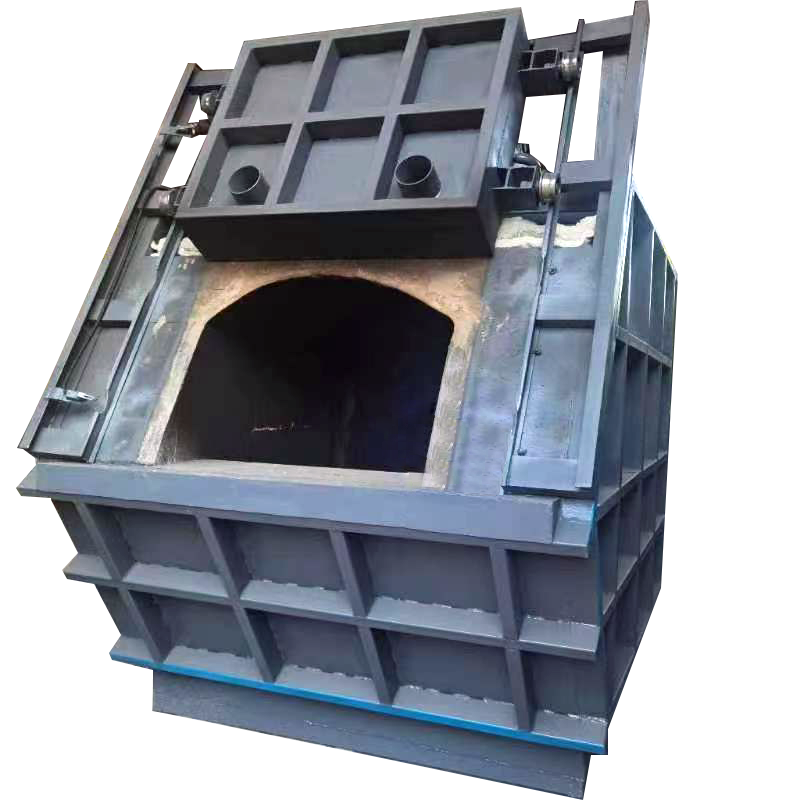

Gas Aluninum Melting Furnace

-

Melting Material:

-

Aluminum Aluminium scrap

-

Materials 1:

-

refractory brick

-

Materials 2:

-

Poured refractory material

-

Characteristic:

-

Simple operation and less maintenance

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

Hongteng

-

Voltage:

-

3*380V

-

Dimension(L*W*H):

-

4060*2100*2950mm

-

Weight (T):

-

15 T

-

Power (kW):

-

10

-

Application:

-

Melting Metal

-

Product Name:

-

Gas Aluninum Melting Furnace

-

Melting Material:

-

Aluminum Aluminium scrap

-

Materials 1:

-

refractory brick

-

Materials 2:

-

Poured refractory material

-

Characteristic:

-

Simple operation and less maintenance

We are factory,we can produce 500Kg-10T capacity aluminum melting furnace gas tilting Gas energy saving aluminum melting furnace

we can also produce matching aluminum ingot production lines.

Product Description

1.Environmental protection and energy saving: Gas-fired aluminum melting furnaces use clean energy (such as natural gas or light diesel) as fuel. The exhaust gas emissions generated during the combustion process are low, causing little environmental pollution and helping to achieve green production.

2.Efficient melting: Due to the high gas combustion efficiency, the aluminum melting furnace can heat aluminum materials quickly and evenly, thereby shortening the melting time and improving production efficiency.

3T non-tilting gas-fired aluminum melting furnace

3T non-tilting gas-fired aluminum melting furnace

Technologicalt Process

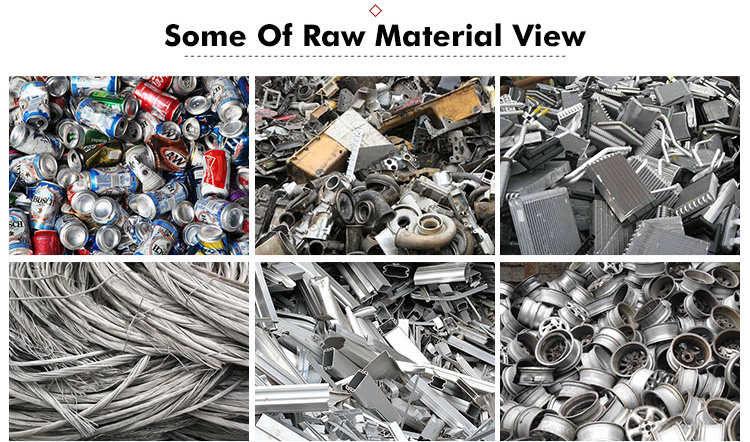

1. Can melt all kinds of aluminum cans ,aluminum powder,aluminium wires,aluminium ingots,aluminum wheels,aluminum alloy door window etc

2. From aluminum scraps to final ingots,including the treatment of aluminum ash after melting. the recovery efficiency will be around

85%-92%.

Product Feature

1.Low operating costs: Compared with electric heating crucible furnaces, gas-fired aluminum melting furnaces have lower energy

consumption and significantly reduced operating costs. The equipment uses refractory bricks + poured refractory material, which

makes the equipment less likely to be damaged and has a longer service life

consumption and significantly reduced operating costs. The equipment uses refractory bricks + poured refractory material, which

makes the equipment less likely to be damaged and has a longer service life

2. Using high-quality poured refractory material,

3. The average life of the melting furnace can be extended by more than 50%.

4.. Example: Aluminum cans, from scraps to final ingots, the recycling efficiency can reach 85%-92%

shortages to avoid the trouble of power expansion and ensure the smooth progress of production.

6.

Safe and reliable: The gas-fired aluminum melting furnace is reasonably designed, with water flowing out from the bottom, and complete safety protection measures, such as overheating protection, flameout protection, etc., to ensure safety and reliability during the production process.

|

Specification and Technical Parameter

|

|

|

|

|||

|

Capacity

|

Powder

|

Voltage

|

Melting Time

|

|||

|

1000kg

|

8KW

|

3*380V

|

120 Minutes

|

|||

|

2000kg

|

10KW

|

3*380V

|

120 Minutes

|

|||

|

3000kg

|

15KW

|

3*380V

|

180 Minutes

|

|||

|

5000kg

|

20KW

|

3*380V

|

180 Minutes

|

|||

Recommend Products

Why Choose Us

Certifications

Hot Searches