- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building, building industry,home furnishing

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Vinco

-

Model Number:

-

Vinco

-

Type:

-

acoustic material

-

Product name:

-

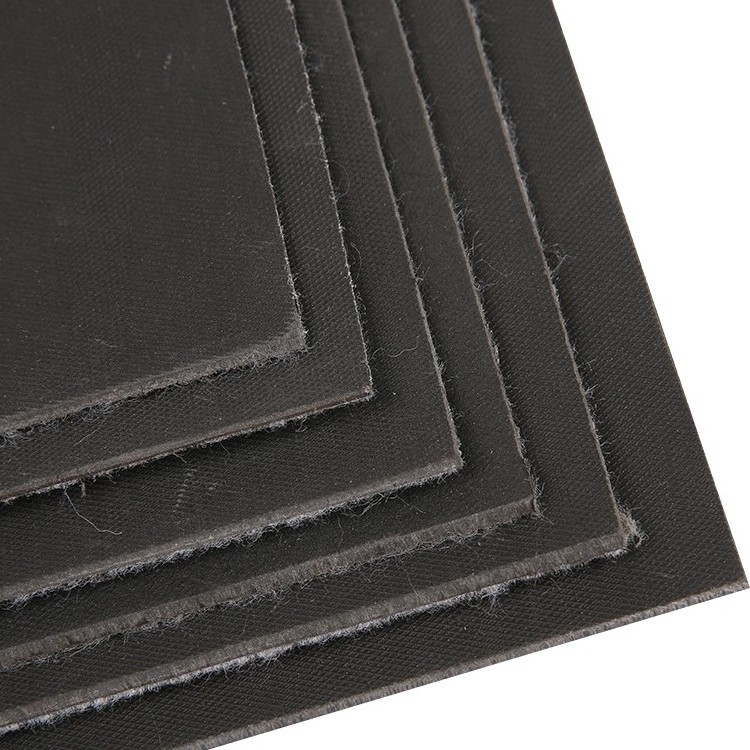

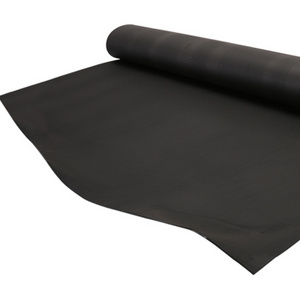

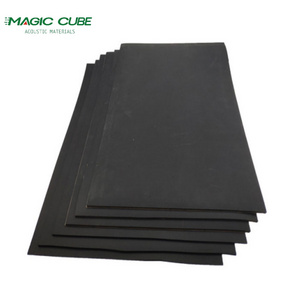

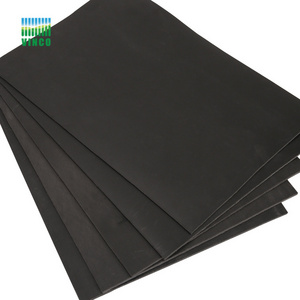

3mm thickness high density black mass loaded vinyl

-

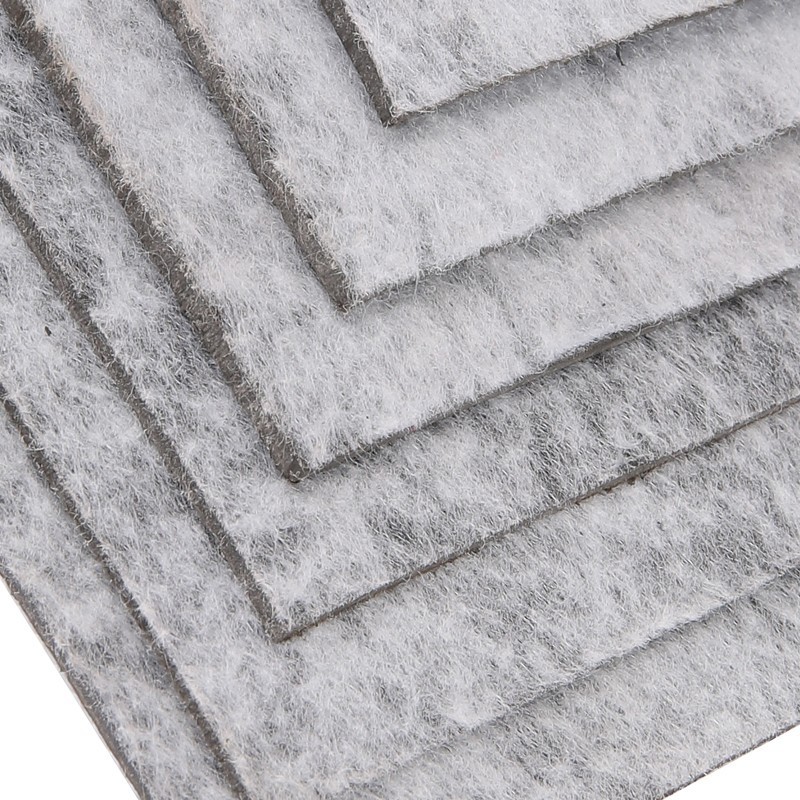

Material:

-

rubber/PVC

-

Size:

-

1200*5000mm/1200*10000

-

Thickness:

-

2mm 3mm 4mm

-

Function:

-

Fire Resistant,sound insulation

-

Density:

-

22-42kg/roll

-

Feature:

-

Fireproof,high density

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

NONE

-

Project Solution Capability:

-

NONE

-

Application:

-

Office Building, building industry,home furnishing

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Vinco

-

Model Number:

-

Vinco

-

Type:

-

acoustic material

-

Product name:

-

3mm thickness high density black mass loaded vinyl

-

Material:

-

rubber/PVC

-

Size:

-

1200*5000mm/1200*10000

-

Thickness:

-

2mm 3mm 4mm

-

Function:

-

Fire Resistant,sound insulation

-

Density:

-

22-42kg/roll

-

Feature:

-

Fireproof,high density

Application

moisture resistant plaste soundproof pad are used as skit board sheets, bride bearing pads, shot plasting sheets, high tensile tangum sheets, commercial sheet with or without cotton/nylon insertion etc.

Method:

(1) clear up the walls.

(2) install the vibration attenuation keels, the interval is about 600mm, the interspace can be filled with sound-absorption cotton. (To avoid the rigid contact, laying sound insulation blanket in the keel internal nail place)

(3) install plasterboard to the keel, then stick to sound insulation blanket, again the fire-sound proof composite board, use multi-use mucilage or screws fix the sound insulation blanket.

(4) sealed all the joint places with building sealant.