- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM China

-

Voltage:

-

380V/220V (It depends on your country)

-

Dimension(L*W*H):

-

2827*2800*2371mm(L*W*H)

-

Power (kW):

-

4 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model No.::

-

LTRZ-100

-

Working volume:

-

130 L

-

Heating area for homogenizing tank:

-

1.2 square meters

-

Homogenizing motor:

-

4 kw

-

Rotating speed:

-

2800 r/min

-

Frame and scrapper motor:

-

1.5 kw

-

Working volume of the oil pot:

-

60 L

-

Working volume of the water pot:

-

80 L

-

Water circulation vacuum pump (KW):

-

1.45 kw

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

0 - 2800 r.p.m

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LTPM China

-

Voltage:

-

380V/220V (It depends on your country)

-

Dimension(L*W*H):

-

2827*2800*2371mm(L*W*H)

-

Power (kW):

-

4 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Model No.::

-

LTRZ-100

-

Working volume:

-

130 L

-

Heating area for homogenizing tank:

-

1.2 square meters

-

Homogenizing motor:

-

4 kw

-

Rotating speed:

-

2800 r/min

-

Frame and scrapper motor:

-

1.5 kw

-

Working volume of the oil pot:

-

60 L

-

Working volume of the water pot:

-

80 L

-

Water circulation vacuum pump (KW):

-

1.45 kw

Products Description

The LTRZ-100 Vacuum Emulsifying Mixer is composed of main pot(emulsifying pot),a water phase pot and an oil phase pot, vacuum unit, up-and down system, electrical control system and the motor frame etc.

The main pot is composed of the cut-off mixing pot, cut-off mixer unit, circulating system and the stirring system etc.

The materials are sucked into emulsifying pot by transportation pipe under the vacuum state, or it also can be put from the feed inlet.

1. I'm not sure which emulsification machine is suitable for me.

2. Want to know more about the emulsifier.

3. Customized emulsification machine.

If you have the above questions, please

Contact us

! We will provide you with quality solutions!

Technical Data

|

Model

|

LTRZ-50

|

LTRZ-100

|

LTRZ-200

|

LTRZ-350

|

|||

|

Total Volume (L)

|

70

|

140

|

260

|

450

|

|||

|

Feeding Volume kg/batch

|

30-50

|

60-100

|

90-200

|

170-350

|

|||

|

High speed motor (kw)

|

3

|

4

|

4

|

5.5

|

|||

|

Rotation Speed of high speed motor

|

1000-4000

|

|

|

|

|||

|

Rotation Speed of frame type scraper motor

|

20-60

|

|

|

|

|||

|

Oil tank volume (L)

|

30

|

60

|

100

|

350

|

|||

|

Water tank volume (L)

|

45

|

85

|

160

|

300

|

|||

Features

1.

Complex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

2. Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

3. Homogenizer is installed on boiler bottom to increase motor power more thoroughly and strongly. During fewproduction, it can exert homogenizing effect fully;

4. Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high -capability cut,rubbing,centrifugal to make sure exquisite and slick cream; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.

5. Homogenizing vacuum emulsifier mixer can choose frequency conversion timing homogenizer and highest rotate speed is 4500 r/min.

2. Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

3. Homogenizer is installed on boiler bottom to increase motor power more thoroughly and strongly. During fewproduction, it can exert homogenizing effect fully;

4. Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high -capability cut,rubbing,centrifugal to make sure exquisite and slick cream; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.

5. Homogenizing vacuum emulsifier mixer can choose frequency conversion timing homogenizer and highest rotate speed is 4500 r/min.

Products

Workshop

Product Details

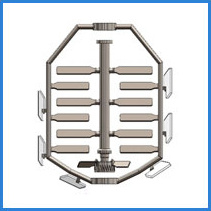

High Shear Homogenizer

Fast agitator:

The three-way rotor and stator components are optional and installed at the bottom or top of the container, providing multiple interchangeable configurations.

Frame Mixer

Dead-end stirring,with sufficient mixing area and good stirring effect.

Hot Searches