- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

380V/50HZ/3phase

-

Dimension(L*W*H):

-

6mx10mx12m

-

Warranty:

-

12months

-

Weight (KG):

-

20000 KG

-

wood chipper:

-

make the log and branch into wood chips

-

Belt Conveyor:

-

Transport the wood chips into hammer mill

-

Hammer mill:

-

make the chips into sawdust

-

Belt conveyor:

-

transport the sawdust into mixer

-

Mixer:

-

mixture multiple sawdust

-

bucket evevator:

-

transport the sawdust into pellet mill

-

wood pellet machine:

-

make the sawdust into pellets

-

bucket elevator:

-

transport into cooler

-

cooler:

-

make the Pellet into room temperature

-

Packing machine:

-

packed the pellets as your request

-

Certification:

-

CE ISO

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1000 - 20000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rotexmaster

-

Voltage:

-

380V/50HZ/3phase

-

Dimension(L*W*H):

-

6mx10mx12m

-

Warranty:

-

12months

-

Weight (KG):

-

20000 KG

-

wood chipper:

-

make the log and branch into wood chips

-

Belt Conveyor:

-

Transport the wood chips into hammer mill

-

Hammer mill:

-

make the chips into sawdust

-

Belt conveyor:

-

transport the sawdust into mixer

-

Mixer:

-

mixture multiple sawdust

-

bucket evevator:

-

transport the sawdust into pellet mill

-

wood pellet machine:

-

make the sawdust into pellets

-

bucket elevator:

-

transport into cooler

-

cooler:

-

make the Pellet into room temperature

-

Packing machine:

-

packed the pellets as your request

-

Certification:

-

CE ISO

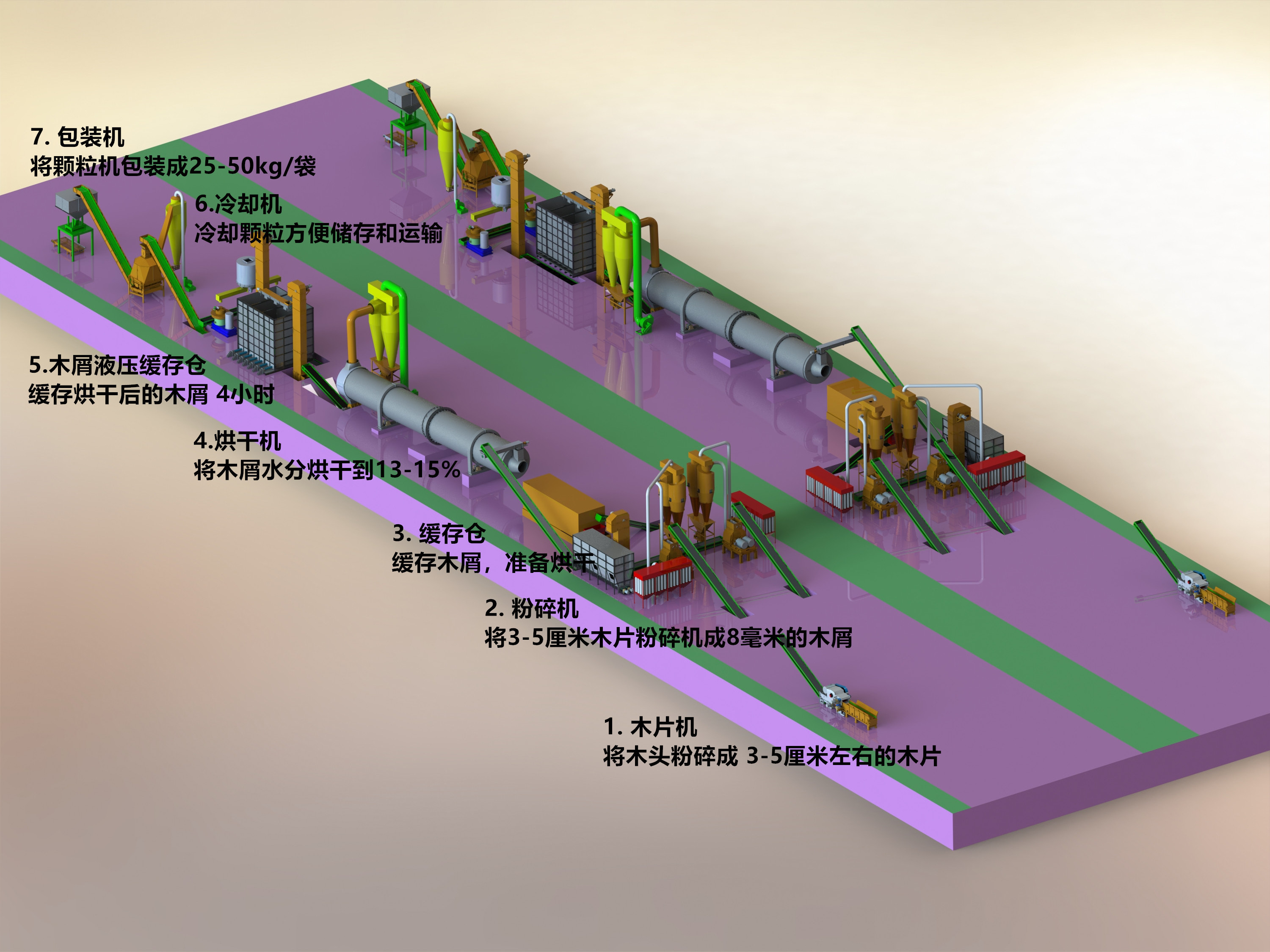

Sawdust & wood chips pallet production line, forest waste pelleting machinery plant

I ntroducing for wood chips pallet production line

1. wood pellet line can press 6.8.10mm diameter biomass fuel pellet and fertilizer pellets ,

such as biomass waste from sawdust, rice husk, coffee husk, agricultural stalk, straw, peanut shell, palm shell, etc The length of final pellet can be adjusted.

2. Capacity of wood pellet line is from smaller 500kg/h to bigger10ton/h , hundreds of lines are installed

in China and abroad, such as Bulgaria, Denmark, Sweden, Greece Romania, Hungary, Japan, Korea, Malaysia, India, Vietnam..

3.The wood pellet line full automatic lubricated spare parts oil systems , which can lubricate rollers,

shaft, bearings and gears automatically every two hours, the pressure between rollers and die can be adjusted automatically to fit for different materials pressure ratio.

4. Spare parts of the wood pellet plant are made by ourselves, mostlyare made by our own CNC systems, through high technology heat treatment, we can ensure its high quality and good precision.

Complete wood pellet processing:

1. wood chips pallet production line ----Raw materials Prepared (if the raw material is wood log wood branch need make into wood chips by wood chipper)

Wood Pellets is mainly made of any wood waste and biomass particles, such as wood sawdust, wood shavings, wood chips, wood logs, straw, rice husk, coffee husk etc. At a wood pellet plant, raw material need to be well prepared before pelletizing, then get dried, compressed, and formed into small eraser-sized bits, the wood pellets get from wood pellet plant are clean, pleasant smelling and smooth to touch.

2. wood chips pallet production line ----Drying process – Rotary Dryer

After crushing process, the wood and biomass material need to be well conditioned on moisture before pelletizing. The best moisture content to pelletizing is about 14-16%. Our rotary dryer is made up of burning stove and main rotary dryer which is high efficiency in drying the wood and biomass material. It use steam to heat air and contact material to remove certain degree of moisture. It is very important for wood pellet plant to using moisture detector which will determine the most suitable moisture before pelletizing.

3. wood chips pallet production line ---Crushing process – Hammer mill

The hammer mill is a machine whose purpose is to crush materials by the collision between the high-speed hammer and materials. Our SFSP series chipping and crushing machine is your best choice. It mill raw material like tree branch, wood shavings, wood chips, wood logs, cotton stalk, corn stalk, wheat straw etc, with size less than 50mm (diameter). After milled, the output size can reach diameter 3-5 mm, then it is pushed to next process to get dried and pelletized.

4. wood chips pallet production line ---Mixing process - --Mixer

5. wood chips pallet production line ---Pelletizing process - Wood pellet mill

Ring Die wood pellet machine is the heart of the pellet machine production line. The Pellet machine is widely used in compacting of wood, straw, other biomass sources into pellet. Capacity ranges from 1T to 10T per hour. Our MZLH series pellet mill adopt SKF bearings from Sweden and NSK bearings from Japan, the motors in the wood pellet is from Siemens, high quality components make the pellet mill more efficient and durable.

6. wood chips pallet production line ----Cooling process - Pellet cooling machine

After the pelletizing process, the temperature of the wood pellet is about 60-80 degrees Celsius, and the moisture content of the wood pellets is about 15%. A cooler must then be used to reduce the moisture content of the wood pellet to about 3-4%, thereby making the wood pellet easy to store. However, some customers said that the local climate is very humidity, they want to cool the wood pellets with moisture 7-8%. It is no problem, our new stabilizer combined cooler can do it well.

7. wood chips pallet production line ----Packing process - Pellet packing machine

After cooling process, the wood pellets will not directly enter into the fuel process, avoiding the wood pellet affected with damp, the packing process is very necessary. The packing process is effectively handled by our Semi-Auto Packing Machine.

Successful cases of wood chips pallet production line

Finished wood Pellets made by wood chips pallet production line

Welcome to contact me to know more information

|

wood pellet line |

|

|

Contact person |

Nancy Chai |

|

|

sales (at)rotexmaster.cn |

|

Fax |

0086 053167880768 |

|

Phone |

0086 15550063221 |

|

Face book |

Nancy Chai |