- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

8KW

-

Dimension(L*W*H):

-

750*700*1250cm

-

Weight (KG):

-

18900

-

Product name:

-

Foundry Green Sand Casting Machine

-

Foundry Machine:

-

Sand Molding Production Line

-

Capacity:

-

1000~15000tons/year

-

Molding machine:

-

Sand Jolt Squeeze Molding Machine

-

Feature:

-

High Efficency

-

Advantage:

-

Foundry Producing Line Machine

-

Casting plant:

-

Green Sand Casting Line

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Metal Casting Molding Line

-

Brand Name:

-

TZZJ

-

Voltage:

-

380V/220V

-

Power:

-

8KW

-

Dimension(L*W*H):

-

750*700*1250cm

-

Weight (KG):

-

18900

-

Product name:

-

Foundry Green Sand Casting Machine

-

Foundry Machine:

-

Sand Molding Production Line

-

Capacity:

-

1000~15000tons/year

-

Molding machine:

-

Sand Jolt Squeeze Molding Machine

-

Feature:

-

High Efficency

-

Advantage:

-

Foundry Producing Line Machine

-

Casting plant:

-

Green Sand Casting Line

-

Certification:

-

ISO

Product Overview

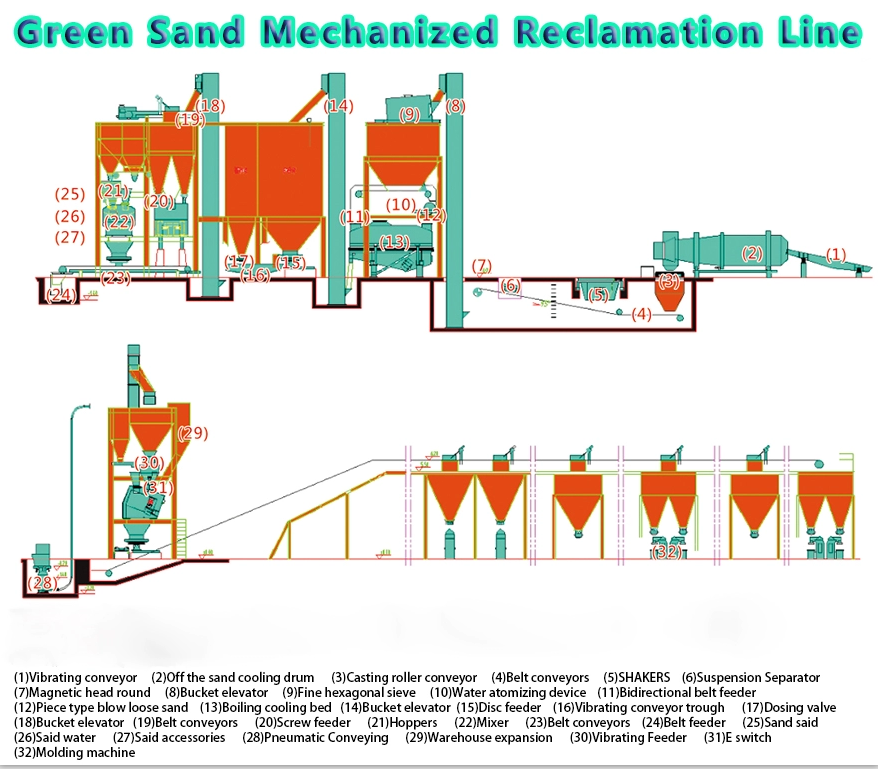

Equipment usage:

Clay sand clay as binder type configuration (core) sand.Implementation of sand processing mechanization is an important part of casting production.The stand or fall of core sand preparation directly affect the quality of the casting production and the improvement of production and reduce cost;Due to the complexity of blasting process, clay sand treatment and transportation workload is very large, and the environment is very bad, so sand processing mechanization is an important part of the casting production.Sand treating section modeling for core is the main task of the ministry to provide qualified sand and core sand.

Equipment introduction: Clay sand production line

Vibration conveyor, cast hanging conveyor, belt conveyor, magnetic separation machine, winding machine, hexagonal mesh, sand library, two-way cooling bed, hoisting machine, belt machine, boiling reclaimer, belt conveyor, hoist, discharger, belt machine, sand library, the disc feeder, belt conveyor, hoist, belt conveyor, exhaust ventilator, accessories, two-way feeder, screw feeder, accessories electronic scale sand mixing machine, belt machine, the disc feeder.

FEATURES AT A GLANCE

Semi-automatic molding line

High efficiency rotor sand mixer

Fully automatic horizontal molding machine

|

Model

|

z148

|

|

Foundry flask maximum dimension(mm)

|

800 * 600* 300

|

|

Worktable dimension(mm)

|

900*730mm

|

|

Jolting load(kgf)

|

600

|

|

Air pressure (Mpa)

|

0.6

|

|

Compressive stress(kgf)

|

10000

|

|

Type

|

GS20-55

|

|

Disc diameter

|

2000mm

|

|

Productivity

|

20-80t/h

|

|

Main motor power

|

55kw

|

|

Rotor motor power

|

2*30kw

|

|

Spindle speed

|

31.72r/min

|

|

Rotor speed

|

1270r/min

|

PRODUCT CONFIGURATION

Ring casting line

Molding line workshop

Sand production line

Successful Project

Automatic molding line

Molding casting line

Casting molding line

SIMILAR PRODUCTS

Company profile

Qingdao Tianzhuang casting Machine Industry and Trade Co., Ltd is a professional manufacturer of foundry machinery, composed of engineering and technical personnel engaged in the foundry machinery industry for many years. Our company can undertake design, casting, installation, commissioning and other turn-key projects of clay sand, resin sand, water glass sand, lost foam and V method production line machinery and chemical department, as well as various stand-alone and spare parts business.

The company adhering to the concept of 'quality first, customer first', and create brilliant together with colleagues in the

casting industry.

The company adhering to the concept of 'quality first, customer first', and create brilliant together with colleagues in the

casting industry.

FAQ

Q: How many days do you need to produce this machine?

A: If no stock machine. Usually 15-20days for shot blasting machine and green sand machine.45days for production line equipments.

Q: What's your machine quality guarantee?

A: Usually it's one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q: Can you instal the machine overseas?How long will it take?

A: YES, we have rich-experienced install team to instal the machine for our customers worldwide.

Q: Can i have your quotation? A: First, please offer us the information of your material size, without these parameter, we are not able to recommend you the suitable machine. Q : How to operate and maintain the machine? A : First, we will provide a professional and detailed USER GUIDE to you with the machine; Second, we will debug the machine in the best status for you; At last, we also provide abroad technical training service. Q : Where is your factory located ? How can I visit it ? A : Our factory is located in Qingdao city,Shandong province,China. When you reach Qingdao air port,we will pick you up. Q :What’s dimension of your workpiece ? A : In order to configure suitable size machine for you. we should get your info. We can professional design as your requirement.

Packing&Shipping

PACKING: EXPORT PACKING:big parts on a wooden pallet and wrapping by film, single parts put together on wooden pallet and wrapping by film, precise parts packing by wood. (Packing woods are not recycled.)

SHIPMENT MARK(S): On the surface of each package, a corresponding shipping mark in the English language shall be stenciled legibly in fadeless or shipping labels tie on non-packing packages in the English language.

PACKING: EXPORT PACKING:big parts on a wooden pallet and wrapping by film, single parts put together on wooden pallet and wrapping by film, precise parts packing by wood. (Packing woods are not recycled.)

SHIPMENT MARK(S): On the surface of each package, a corresponding shipping mark in the English language shall be stenciled legibly in fadeless or shipping labels tie on non-packing packages in the English language.

Hot Searches