- Product Details

- {{item.text}}

Quick Details

-

Power:

-

According to the size

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1 kg

-

After-sales Service Provided:

-

No overseas service provided

-

dehumidifiers/ahus:

-

customized

-

Model Number:

-

PPS

-

Style:

-

High Quality

-

Application:

-

Desiccant Dehumidifier for Plastic

-

Diameter:

-

150-400mm

-

Thinckness:

-

200mm

-

Product:

-

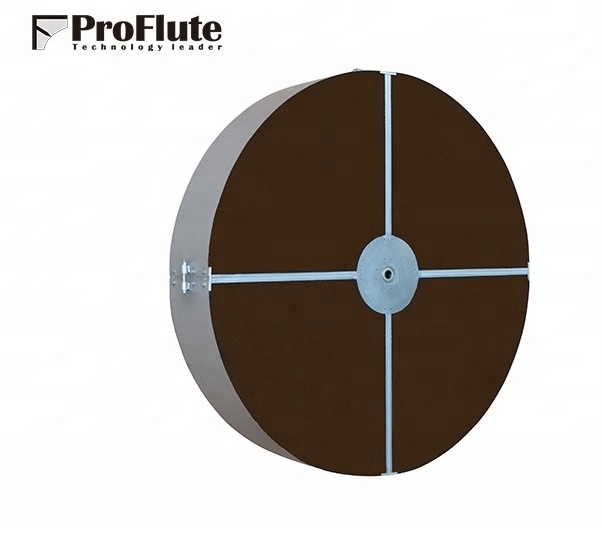

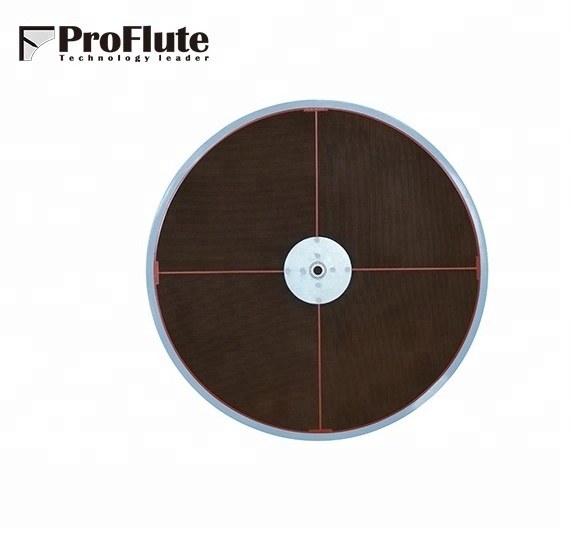

Desiccant Wheel

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Sweden

-

Brand Name:

-

Proflute

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

According to the size

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1 kg

-

After-sales Service Provided:

-

No overseas service provided

-

dehumidifiers/ahus:

-

customized

-

Model Number:

-

PPS

-

Style:

-

High Quality

-

Application:

-

Desiccant Dehumidifier for Plastic

-

Diameter:

-

150-400mm

-

Thinckness:

-

200mm

-

Product:

-

Desiccant Wheel

-

Certification:

-

ISO9001

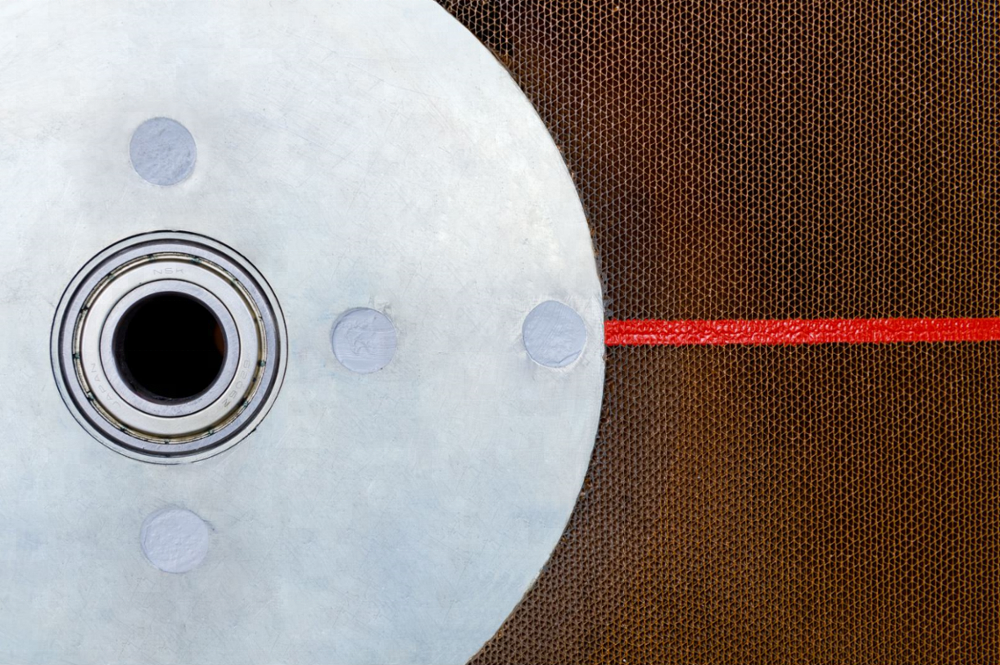

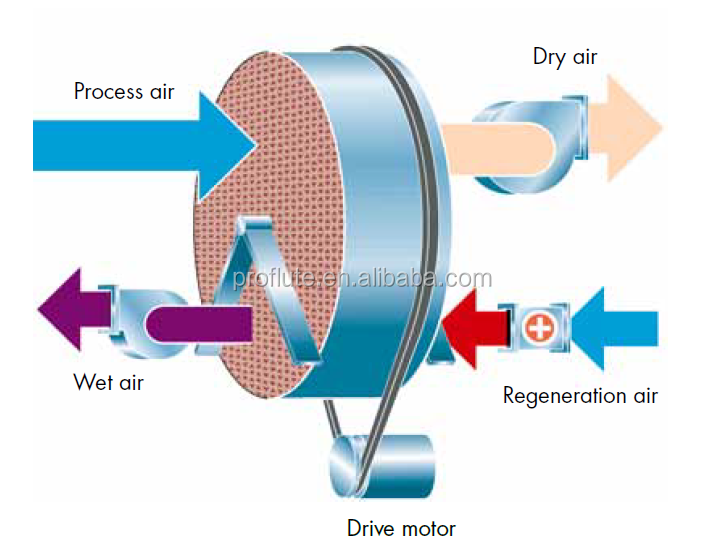

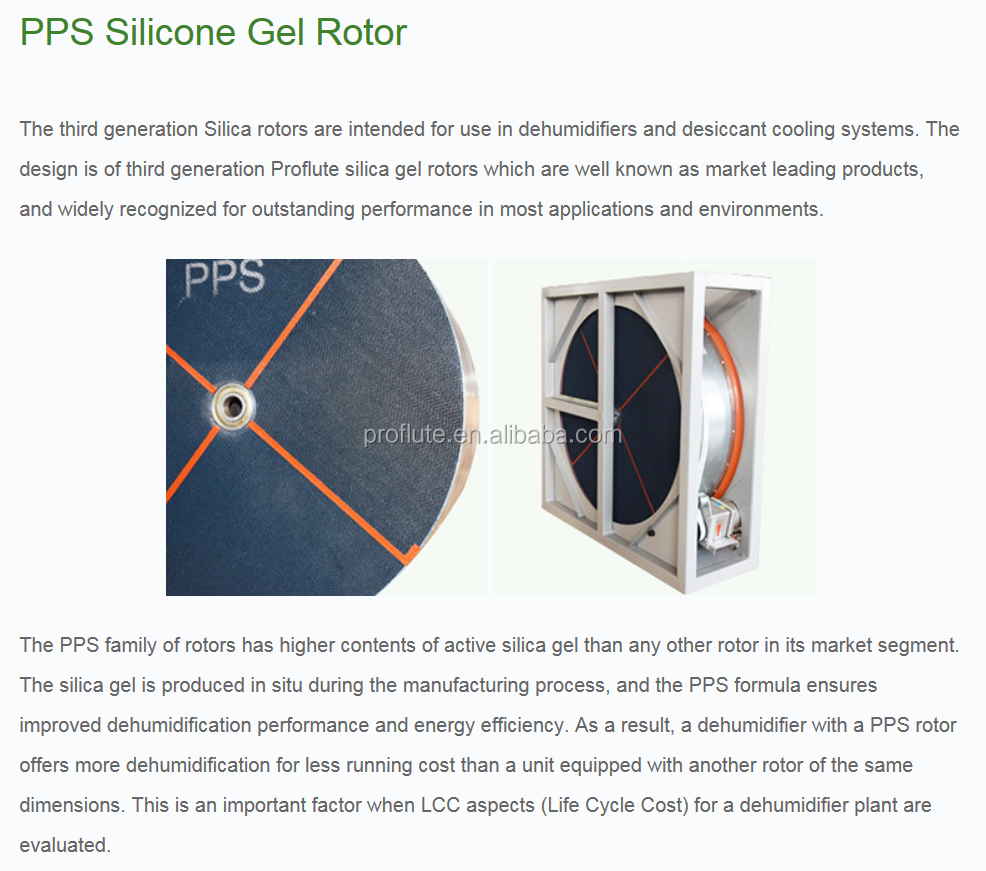

SAT Co. specializes in manufacturing desiccant dehumidification rotors and cassettes. It imports the desiccant media from its Swedish head-company ProFlute to make various specifications of rotors meeting dehumidification requirement of different environment and applications .

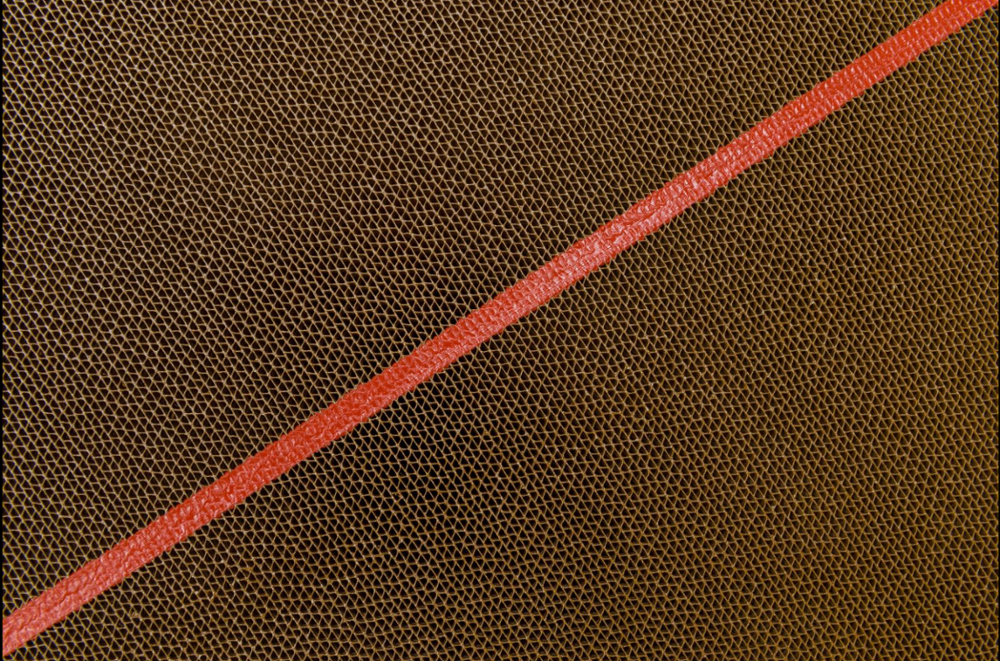

• Highest desiccant content

The PPS rotor has a very high, 82%, active Silica Gel content.

It can be used for most environment and applications.

-

Fire Resistance

The rotor media provided by ProFlute AB has been tested according to ASTME test E-84 and achieved a flame-spread index of 0 and a smoke index 0.

-

Unique moisture adsorption

The density of dry media is approximately 240 kg/m³. The media can pick up approximately 40% of its dry weight as moisture in humid environment. There is no limit for how high relative humidity the rotor can stand as long as the droplets are not introduced into the rotor during operation.

-

Water washable

The rotor can be washed in the water when the rotor is saturated in humid environment. The PPS rotor should be washed with weak non-alkaline detergent.

-

High surface strength

The surface compression strength of the rotor is more than 200kpa.

-

Variety in construction

The various kind of rotor construction could be made according to the customers’ requirement, such as selection of raw material of the metal parts and with or without flange etc. For the large rotors, the knockdown construction will be very convenience for transportation and assembly on site.

So many sizes of rotors can meet dehumidifier manufacturers’ demand and replacement demand for most existing dehumidifiers. The selection software provided by ProFlute can calculate the rotor’s dehumidification capacity, resistance and other characteristic parameter to assist customers to select suitable rotors according to different dehumidification demand .

| Diameter, mm | Available depth, mm | Shaft diameter, mm | Delivered knock-down |

|---|---|---|---|

| 100~350 | 50, 100 or 200 | 20 | No |

| 450~550 | 100,200 or 400 | 20 | No |

| 600~1050 | 200 or 400 | 20 | No |

| 1150~1950 | 200 or 400 | 30 | Can |

| 2000~3000 | 200 or 400 | 40 | Yes |

Polywood Box + Polyfoam

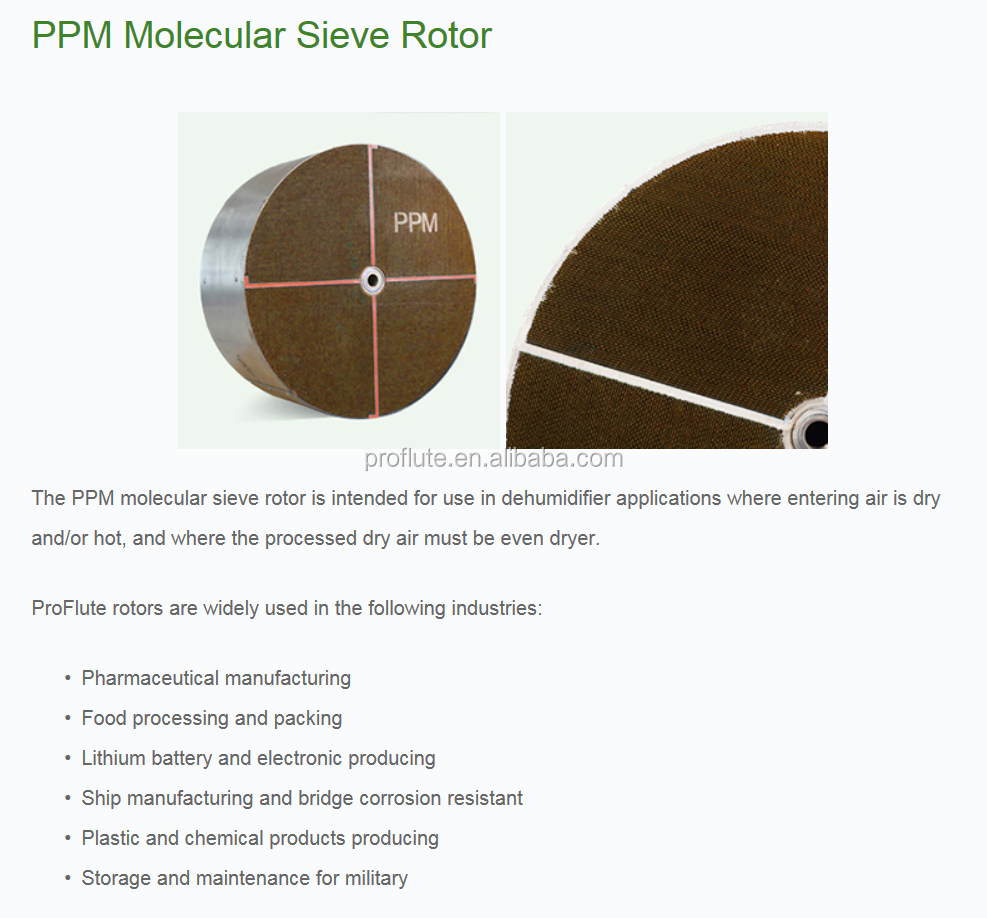

ProFlute rotors are widely used in the following industries :

- Pharmaceutical manufacturing

- Food processing and packing

- Lithium battery and electronic producing

- Ship manufacturing and bridge corrosion resistant

- Plastic and chemical products producing

- Storage and maintenance for military