Shenzhen BWiN Precision Tools Co.,Ltd. is a main professional supplier in CNC Carbide inserts, Turning tools and Milling tools, BWiN manufacture with integration of R&D, Design and Sales. We insists the principles of "High quality, Competitive price and Excellent service."

BWiN manufacture has over 1500 square meter factory area and storehouse. We are leading OED&ODM manufacture many years of experience in this filed. BWiN have various kinds of productc and they are 70% for expert. Our customers are from all over the world, such as North America, Europe, South America, the Middle east, East Asia and Africa. The quality control standards are based on ISO9001 certifications. BWiN relies on advanced automatic machining center and complete testing testing method, control all aspects of production and operation according to the standard process. We have an outstanding team of designers to continuously launch innovative product design, in order to meet the needs of the international marked. Welcome send inquiry to us, we will provide high quality products and excellent service for you!

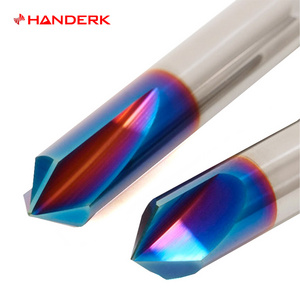

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BWIN

-

Model Number:

-

D3X60L HRC55

-

Product Name:

-

HRC 55 T-Slot Milling Cutter

-

Flute:

-

4 Flutes

-

HRC:

-

55 HRC

-

Workpiece:

-

Alloy steel, stainless steel, cast iron, copper

-

Service:

-

Free Sample

-

Shipment:

-

DHL/TNT/UPS/Fedex/EMS

-

Delivery Time:

-

6-14 Days

Quick Details

-

Material:

-

Tungsten steel alloy

-

Coating:

-

AlTiSiN

-

Warranty:

-

NONE

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BWIN

-

Model Number:

-

D3X60L HRC55

-

Product Name:

-

HRC 55 T-Slot Milling Cutter

-

Flute:

-

4 Flutes

-

HRC:

-

55 HRC

-

Workpiece:

-

Alloy steel, stainless steel, cast iron, copper

-

Service:

-

Free Sample

-

Shipment:

-

DHL/TNT/UPS/Fedex/EMS

-

Delivery Time:

-

6-14 Days

Product Description

|

Product Name

|

45 60 75 Degree Dovetail Groove Trough T Slot T-Slot T-Milling Cutter

|

|

Material

|

Caribde

|

|

Coating

|

AITiN/customized

|

|

Standard

|

ISO

|

|

HRC

|

55

|

|

Coolant:

|

Water, water-soluble oil, and high-flashpoint oil

|

|

OEM

|

Supply

|

|

Suitable For

|

Stainless steel, Carbon Steel, Mould steel, Cast Iron, Cooper

|

|

Application

|

Side milling slotting, T-shaped slotting, deep slotting, plane milling

|

1. Fully enables running at rough machining parameters, resulting in finish surface quality.

2. Excellent performance in machining titanium, stainless steel and high temperature alloys.

3. The coating provides longer tool-life or increased cutting-values.

4. Suitable for all types of steel or metal.

Product Parameters

|

Item Grade

|

HRC45

(YG10X )

|

HRC55

(YL10.2 & WF25)

|

HRC60

(Germany K44 &K40)

|

HRC65

(Sandvik H10F)

|

|

Details

|

Grain size 0.7um

Co10% Flexural strength 3320N/mm 2 |

Grain size 0.6um

Co10% Flexural strength 4000N/mm 2 |

Grain size 0.5um

Co12% Flexural strength 4300N/mm 2 |

Grain size 0.5um

Co10% Flexural strength 4300N/mm 2 |

|

Coating Classifying and Advantage

|

|

|

|

|

|

|||||

|

Item

|

Coating Type

|

AlTiN

|

TiAlN

|

TiSiN

|

NaCo

|

|||||

|

Characteristic

|

Hardness(HV)

|

3300

|

2800

|

4300

|

42(GPA)

|

|||||

|

|

Thickness(UM)

|

2.5-3

|

2.5-3

|

3

|

3

|

|||||

|

|

Oxidation Temp.(°C)

|

900

|

800

|

1000

|

1200

|

|||||

|

|

Friction Coefficient

|

0.35

|

0.3

|

0.25

|

0.4

|

|||||

|

|

Color

|

Black

|

Bronze

|

Bronze and gold

|

Blue

|

|||||

|

|

Advantages

|

High heat stability

|

Normally cutting

|

Suitable for heavy cutting, and high hardness cutting

|

For high precision cutting

|

|||||

|

|

|

Suitable for high speed, dry cutting

|

|

Suitable for cutting mould steel,

stainless steel

|

Suitable for high hardness cutting, mould steel processing

|

|||||

|

|

|

Most suitable for carbide cutting tools, turning insert

|

|

|

|

|||||

Products Show

|

cutting Diameter

|

Angle

|

Avoidance diameter

|

Avoidance length

|

cutting length

|

Shank diameter

|

overall length

|

Flute

|

|

2

|

45°/60°/75°

|

1

|

3

|

0.5

|

4

|

50

|

4

|

|

3

|

45°/60°/75°

|

1.5

|

5

|

0.7

|

3

|

50

|

4

|

|

4

|

45°/60°/75°

|

2

|

6

|

1

|

4

|

50

|

4

|

|

5

|

45°/60°/75°

|

2.5

|

8

|

1.2

|

5

|

50

|

4

|

|

6

|

45°/60°/75°

|

3

|

8

|

1.5

|

6

|

50

|

4

|

|

7

|

45°/60°/75°

|

3.5

|

10

|

1.7

|

7

|

60

|

4

|

|

8

|

45°/60°/75°

|

4

|

10

|

2

|

8

|

60

|

4

|

|

9

|

45°/60°/75°

|

4.5

|

15

|

2.2

|

9

|

60

|

4

|

|

10

|

45°/60°/75°

|

5

|

15

|

2.5

|

10

|

60

|

4

|

|

11

|

45°/60°/75°

|

5.5

|

15

|

2.7

|

11

|

60

|

4

|

|

12

|

45°/60°/75°

|

6

|

15

|

3

|

12

|

60

|

4

|

|

14

|

45°/60°/75°

|

7

|

20

|

3.5

|

14

|

65

|

4

|

|

16

|

45°/60°/75°

|

8

|

20

|

4

|

16

|

65

|

4

|

|

20

|

45°/60°/75°

|

10

|

25

|

5

|

20

|

65

|

4

|

Other Products

Our Company

FAQ

1. Are you manufacturer or trading company?

We are professional manufacturer with more than 10 years experience in this field.

2. How to place an order?

1.Fill your Order List in our online Inquiry System.

2.Directly contact our salesperson by E-mail / Skype / Whats App

We will make a feedback to you ASAP after receive your order list.

3. What is your payment terms?

T/T, Paypal, Western Union, Alibaba assurance for different circumstances.

4. What's your delivery way?

Express delivery, DHL, TNT, FEDEX , EMS, air shipping, sea shipping are available for your request.

5. Do you offer OEM?

Yes, we do. We have laser machine lasering your logo and tool specification on the body of tools. Also, we can print customized on plastic boxes.

6. How about the delivery time?

Usually delivery time is 2~3 days after receiving the advance payment. For the customized product, 7-10 days after receiving the advance payment.

Hot Searches