- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MWK

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

110

-

Weight:

-

10000 KG

-

Engineers Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

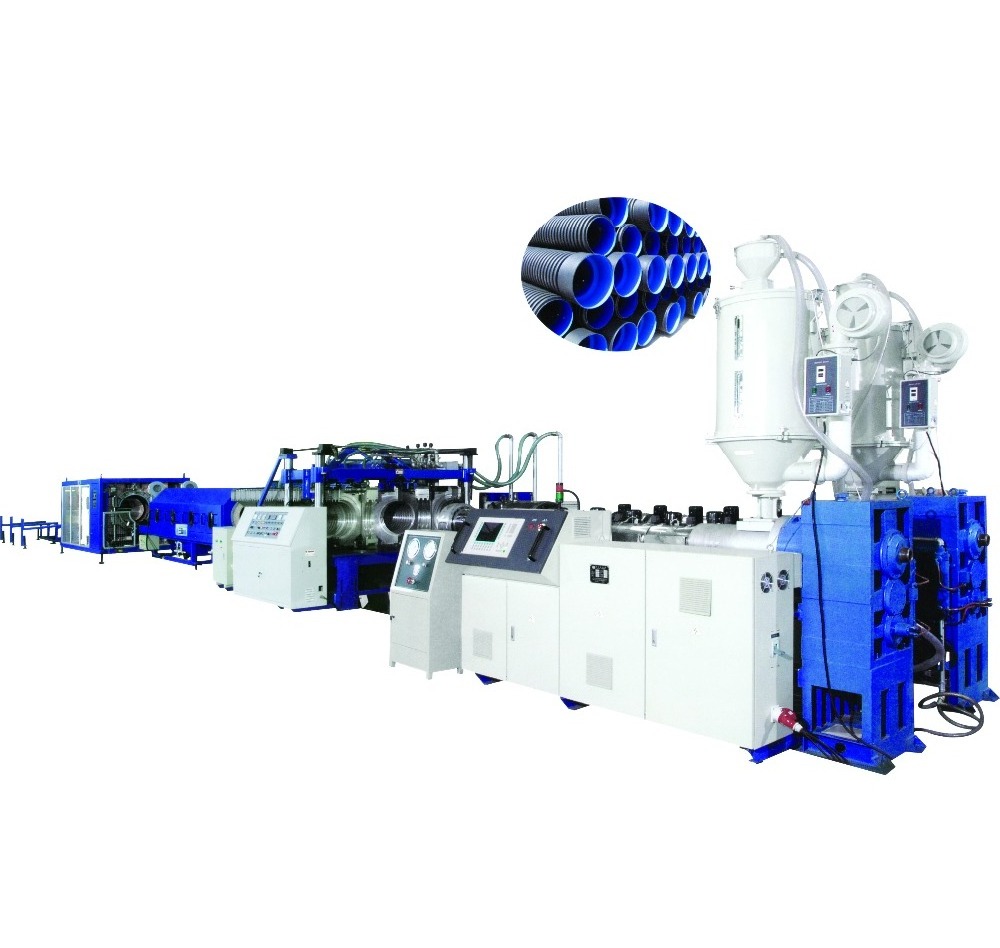

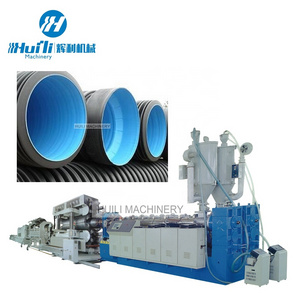

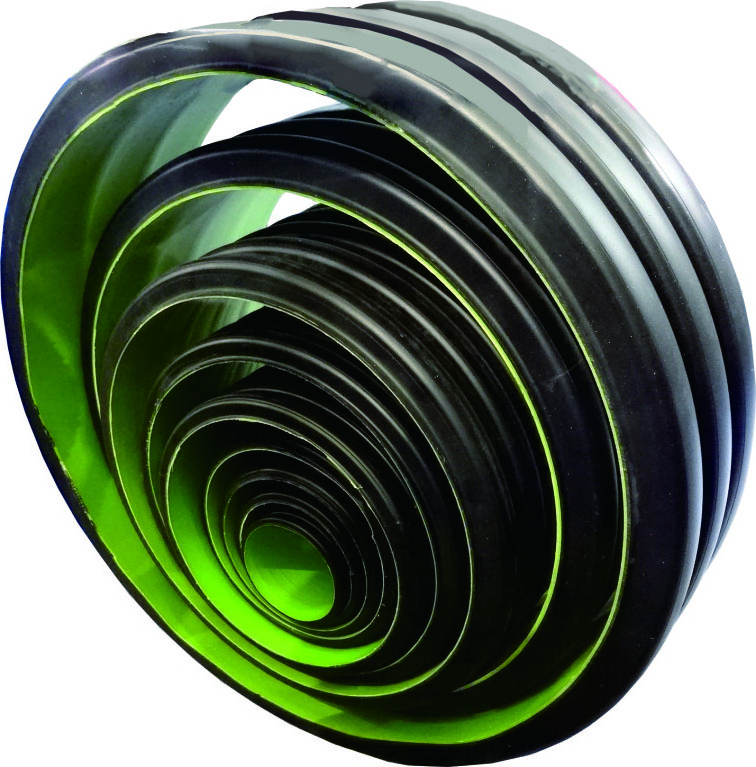

PE, PP and PVC Double Wall Corrugated Pipe Extrusion Line

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support,Online support

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Other

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MWK

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

CAPACITY

-

Power (kW):

-

110

-

Weight:

-

10000 KG

-

Engineers Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

PE, PP and PVC Double Wall Corrugated Pipe Extrusion Line

-

Automatic Grade:

-

automatic

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support,Online support

-

Marketing Type:

-

Ordinary Product

Product Description

Specification

PP and PVC Double Wall Corrugated Pipe Extrusion Line

Application:

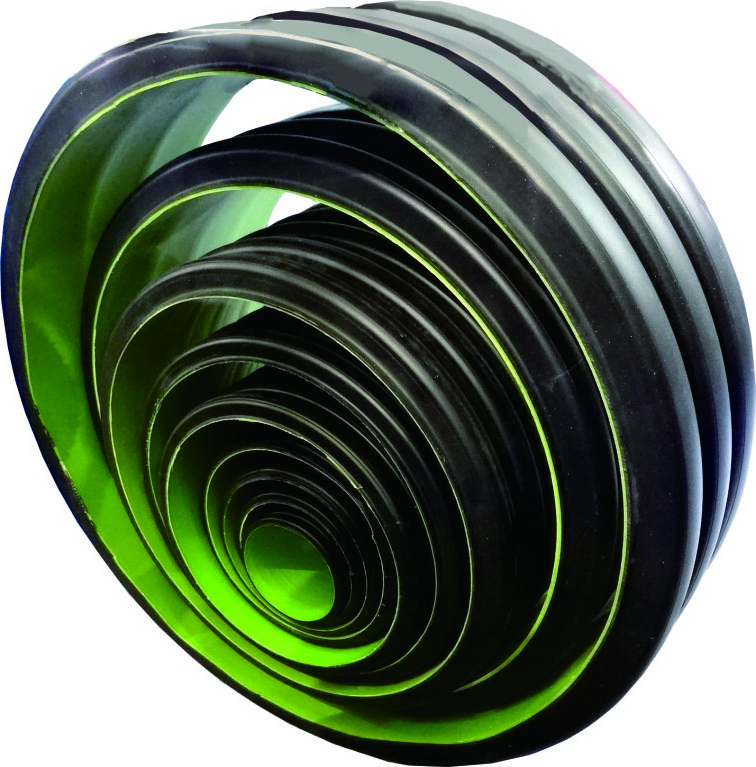

This kind of corrugated pipe is mainly used for underground water

Properties:

It is fully computer controlled, automatic production line. It features high and stable output capacity, and highly automatic operation. Drainage system

Extruder:

Different types of extruder can be selected for the prodcution line

According to the material properies.

For HDPE, you can choose high efficient screw extruder.

For PVC, you can choose conica twin screw extruder or paralll twin screw extruder.

Downstream equipment:

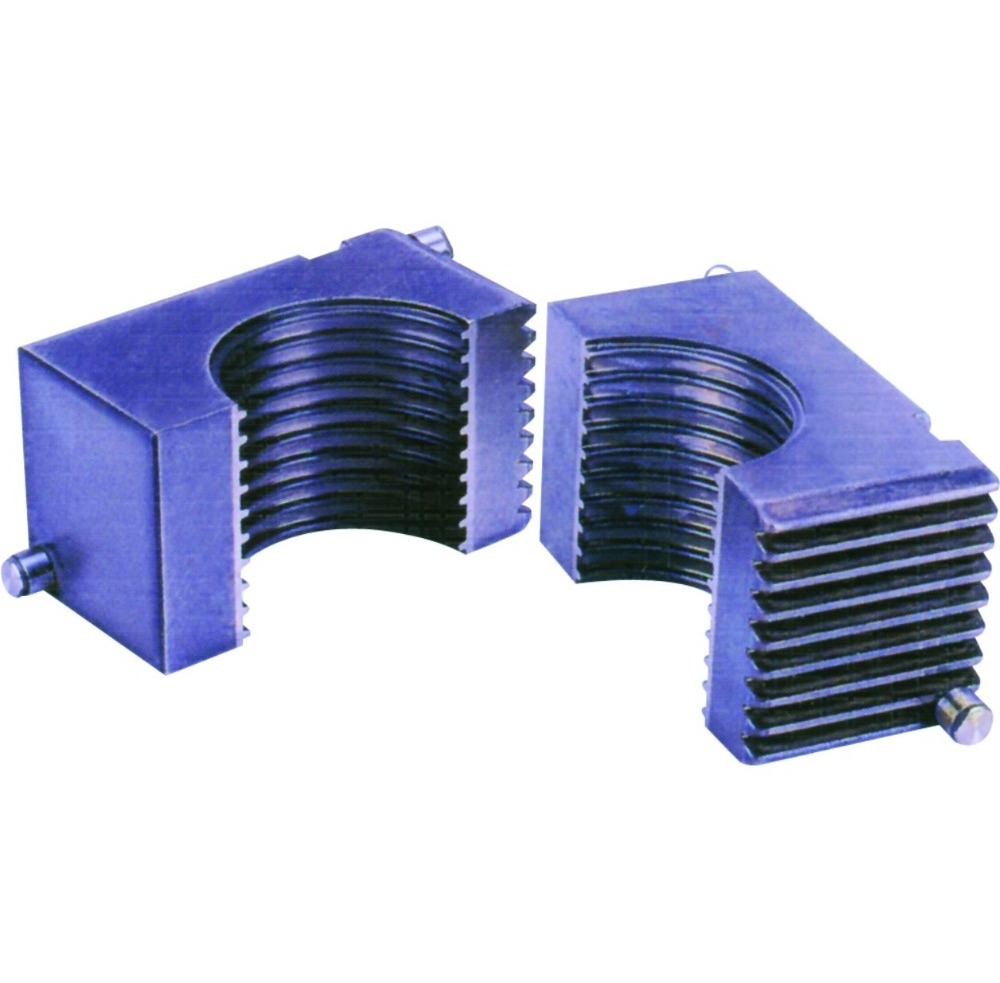

The forming system of this line consists of mould and corrugator. The mould blocks can be easily changed and they may have air or water cooling system. The belling process can also be realized on ine. High precision cutting can be guarateed by rotation type cutting machine. The production line can also be equipment with Siemens program logic control system.

Main Technical Parament:

|

Pipe Diameter

|

Single screw extruder

|

Forming machine

|

Spray bath

|

Planetary saw

|

Stacker

|

|

50-160 (OD mm)

|

SJ-65 x 30

SJ-90 x 30

|

SBZ160A

|

|

SQG160A

|

JGJ1120

|

|

110-250 (OD mm)

|

SJ-90 x 30

SJ- 65 x 33

|

SBZ250

|

LQM2550

|

QG250A

|

JGJC250

|

|

200-400 (ID mm)

|

SJ-90 x 30

SJ- 75 x 33

|

SBZ500C

|

LQM6330

|

QG6330A

|

JGJA500

|

|

500-800 (ID mm)

|

SJ-90 x 33

SJ-120 x 33

|

SBZ1000C

|

LQM1000

|

QG9030A

|

JGJ1000

|

|

800-1200 (ID mm)

|

SJ-120 x 33

SJ-150 x 33

|

SBZ1500C

|

LQM 1500

|

QG1500

|

JGJ1500

|

Hot Searches