- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KARP

-

Voltage:

-

110V, 220V, 230V, 380V, 400V, 415V, 440V, 500V

-

Dimension(L*W*H):

-

As per order

-

Weight:

-

200 KG

-

Product name:

-

Food Processing Vibration Screen Sieve Soya Flour Vibrating Sieving

-

Customized:

-

Acceptable

-

Material:

-

Carbon Steel/Stainless Steel 304/316

-

Motor:

-

Vibrating Motor

-

Function:

-

Grading\Filtering\Remove Impurity

-

Feature:

-

Easy Maintenance

-

Layer(s):

-

1~4 Layers

-

Mesh size:

-

2~500 Mesh

-

Cleaning system:

-

Ultrasonic/Bouncing ball Cleaning System

-

Diameter:

-

400-1500 mm

Quick Details

-

Type:

-

Round

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KARP

-

Voltage:

-

110V, 220V, 230V, 380V, 400V, 415V, 440V, 500V

-

Dimension(L*W*H):

-

As per order

-

Weight:

-

200 KG

-

Product name:

-

Food Processing Vibration Screen Sieve Soya Flour Vibrating Sieving

-

Customized:

-

Acceptable

-

Material:

-

Carbon Steel/Stainless Steel 304/316

-

Motor:

-

Vibrating Motor

-

Function:

-

Grading\Filtering\Remove Impurity

-

Feature:

-

Easy Maintenance

-

Layer(s):

-

1~4 Layers

-

Mesh size:

-

2~500 Mesh

-

Cleaning system:

-

Ultrasonic/Bouncing ball Cleaning System

-

Diameter:

-

400-1500 mm

Product Description

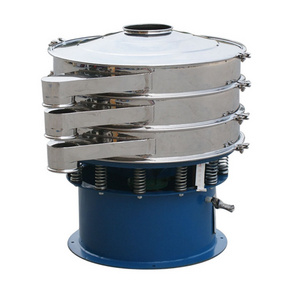

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

Layer: 1 layer Diameter: 800 mm

Layer: 2 layers Diameter: 600 mm

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

is a new type and high precision fine powder sieving machine with characteristics of high efficiency & lower noise. The

fundamental principle of round separator is that the eccentric hammers installed on the top and bottom ends of motor changes the

rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen

surface to achieve the purpose of classification, filtering and removal of impurities.

Details Images

A new type screen mesh frame

Ultrasonic cleaning system

Discharge outlets

Quick clamp

Buffer board &

Viewing port

Valve

Main advantages:

2. Prevent blockages and easy to clean.

3. Simple and efficient design. Less power consumption.

4. No special flooring or foundation is needed and less volume.

5. Long screen life and easy to change the screen mesh.

6. The mesh of screen can be up to 500 mesh, with up to 5 screen decks.

Application Fields

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

is widely used in many industries as below:

1. Chemical industry:

resin, paint, industrial powder, cosmetics, herbal powder, plastic, PVC powder, etc.

2. Food industry:

sugar powder, starch, salt, rice powder, milk powder, soybean milk, egg powder, soy sauce, juice, etc.

3. Metals and metallurgical mining:

aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese

dioxide, electrolytic copper powder, electromagnetic material, grinding powder, refractory materials, kaolin, lime, alumina, heavy

calcium carbonate, quartz sand, etc.

4. 3D Printing materials:

titanium alloy powder, aluminium alloy powder, stainless steel powder, iron base alloy, nickel base

alloy, titanium powder, copper powder, aluminum powder, molybdenum powder.

5. Lithium battery industry:

battery cathode material, battery anode materials, artificial graphite, natural graphite, lithium

iron phosphate, battery material powder, etc.

6. Other industries:

waste oil, waste water, dyeing and finishing waste water, paper making, additives, activated carbon, etc.

Production Process

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

reflects the care taken over selection of components and the high level of precision adopted in manufacture.

KARP MACHINERY makes strict inspections for

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

and other products during producing and before shipment.

Our service:

Customized services:

1. Professional R & D team will develop the new products as you requirements.

2. We can help high-end customers to develop the local market.

3. All packing and shipping can be customized as your requirements.

After-sale services:

If you have any questions or problems of quality after receiving the goods, our customer service Dept. will be always available.

Basis service:

1. Your sample material can be analysed freely in our laboratory.

2. We are online 24 hours a week and will reply your message within 12 hours.

3. We provide the service of booking hotel and ticket for customers and free transportation during visiting our factory.

4. Production lead time and delivery time are guaranteed.

1. Your sample material can be analysed freely in our laboratory.

2. We are online 24 hours a week and will reply your message within 12 hours.

3. We provide the service of booking hotel and ticket for customers and free transportation during visiting our factory.

4. Production lead time and delivery time are guaranteed.

Customized services:

1. Professional R & D team will develop the new products as you requirements.

2. We can help high-end customers to develop the local market.

3. All packing and shipping can be customized as your requirements.

After-sale services:

If you have any questions or problems of quality after receiving the goods, our customer service Dept. will be always available.

Specification

|

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

|

|

|

|

|

|

|||||

|

Model

|

Diameter(mm)

|

Largest particle(mm)

|

Screen mesh

|

Layer

|

Power(KW)

|

|||||

|

KP-400

|

400

|

<10

|

2-500

|

1-4

|

0.22

|

|||||

|

KP-600

|

600

|

<10

|

|

|

0.55

|

|||||

|

KP-800

|

800

|

<20

|

|

|

0.75

|

|||||

|

KP-1000

|

1000

|

<20

|

|

|

1.1

|

|||||

|

KP-1200

|

1200

|

<20

|

|

|

1.5

|

|||||

|

KP-1500

|

1500

|

<20

|

|

|

2.2

|

|||||

Packing & Delivery

Packing for

Food Processing Vibration Screen Vibro Sieve Shaker Soya Flour Vibrating Sieving Machine

.

Outside package: standard export wooden box.

Inner package: stretch film for machine, accessories in carton.

Hot Searches