- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

EPT

-

Product Name:

-

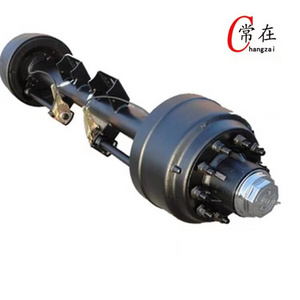

Rubber Torsion Axle with Electric mechanical or hydraulic drum brake

-

Material:

-

Steel

-

Color:

-

Customer Demands

-

Application:

-

Trailer Truck Used

-

Type:

-

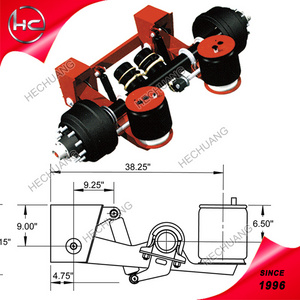

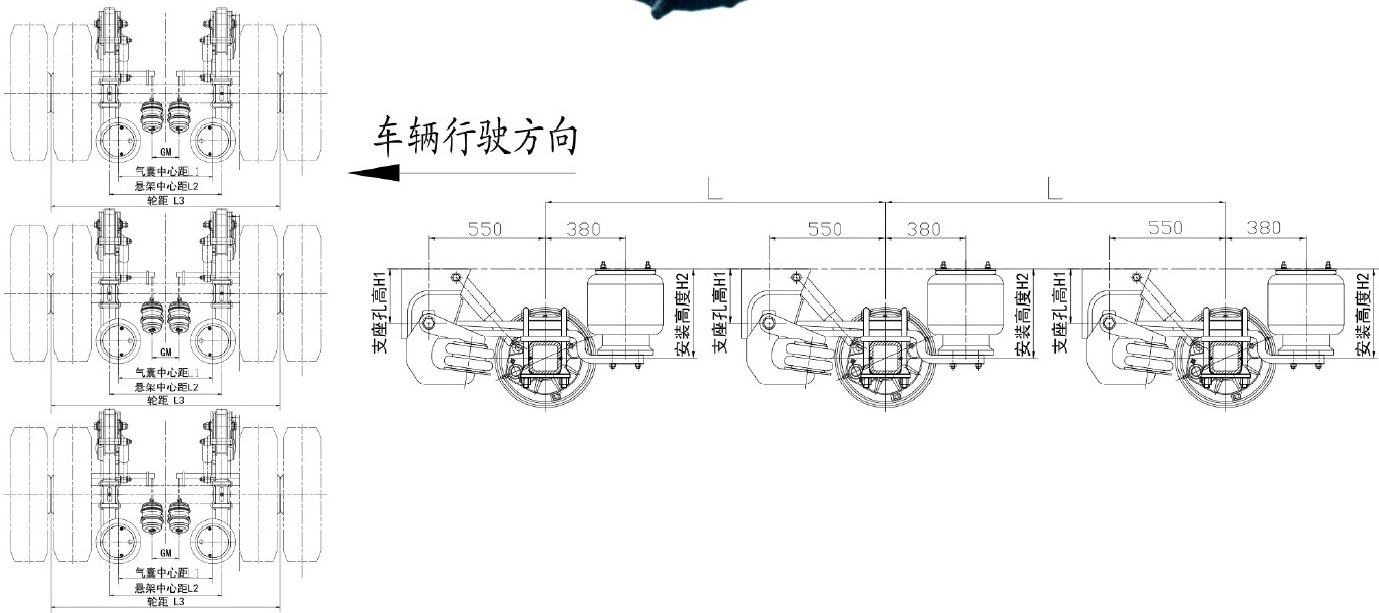

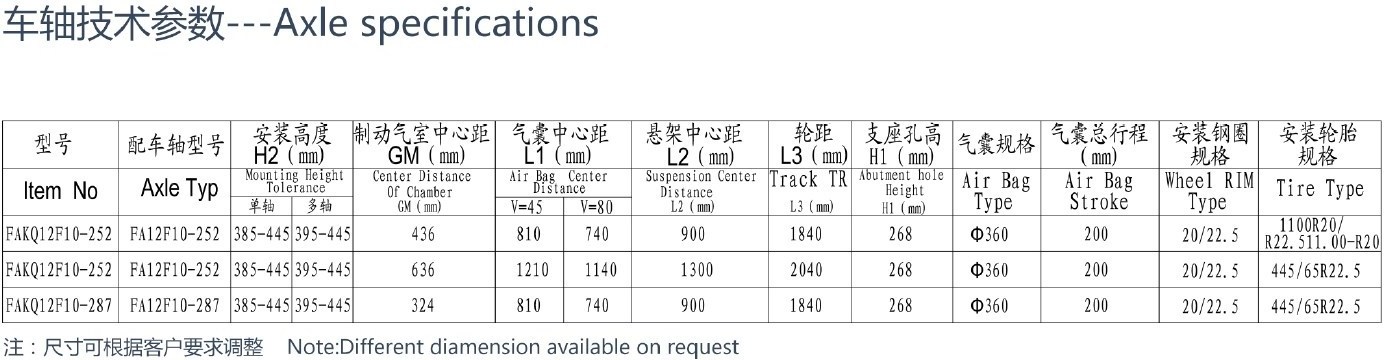

2 /3/4 Axle Trailer Suspension

-

Axle Beam:

-

Square 150*150mm

-

Track:

-

1840mm

-

Axle tube:

-

150X150X12mm

-

P.C.D:

-

335mm

-

Brake size:

-

420*180/420*220

Quick Details

-

OE NO.:

-

OEM

-

Max Payload:

-

2T

-

Size:

-

STANDARD

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

EPT

-

Product Name:

-

Rubber Torsion Axle with Electric mechanical or hydraulic drum brake

-

Material:

-

Steel

-

Color:

-

Customer Demands

-

Application:

-

Trailer Truck Used

-

Type:

-

2 /3/4 Axle Trailer Suspension

-

Axle Beam:

-

Square 150*150mm

-

Track:

-

1840mm

-

Axle tube:

-

150X150X12mm

-

P.C.D:

-

335mm

-

Brake size:

-

420*180/420*220

Product Description

Drop Axle

Trailer axle air suspension refers to a suspension system commonly used in trailers that utilizes air springs or airbags to support the load and provide a smoother ride. Here are some key points about trailer axle air suspension: 1. Air Springs: The trailer axle air suspension system replaces traditional leaf springs or coil springs with air springs or airbags. These air springs are typically made of durable rubber and reinforced with layers of fabric or metal to withstand the load. 2. Load Support: The air springs in the suspension system provide the primary support for the trailer's load. They can be adjusted to accommodate different load weights, providing a more customizable and flexible load support solution. 3. Air Pressure Control: The air suspension system relies on air pressure to adjust the ride height and stiffness of the trailer. Air pressure can be controlled manually or automatically using air valves and an air compressor. This allows for quick adjustments based on the load weight and road conditions. 4. Ride Quality: Trailer axle air suspension offers improved ride quality compared to traditional suspension systems. The air springs absorb road shocks and vibrations, resulting in a smoother and more comfortable ride for both the trailer and its cargo. This can help reduce the risk of damage to sensitive or fragile cargo. 5. Leveling and Height Adjustment: Air suspension systems can be equipped with leveling valves that automatically adjust the trailer's ride height to maintain a level position when loading and unloading. This ensures optimal weight distribution and stability. 6. Variable Load Distribution: Trailer axle air suspension allows for dynamic load distribution, where the air pressure in each air spring can be adjusted individually to optimize load distribution across the trailer's axles. This helps improve handling, traction, and overall stability. 7. Maintenance and Service: Regular maintenance of the air suspension system is essential to ensure its optimal performance. This includes checking for air leaks, inspecting air springs for damage, and maintaining proper air pressure levels. It is also important to follow manufacturer guidelines for servicing the system.

Trailer axle air suspension refers to a suspension system commonly used in trailers that utilizes air springs or airbags to support the load and provide a smoother ride. Here are some key points about trailer axle air suspension: 1. Air Springs: The trailer axle air suspension system replaces traditional leaf springs or coil springs with air springs or airbags. These air springs are typically made of durable rubber and reinforced with layers of fabric or metal to withstand the load. 2. Load Support: The air springs in the suspension system provide the primary support for the trailer's load. They can be adjusted to accommodate different load weights, providing a more customizable and flexible load support solution. 3. Air Pressure Control: The air suspension system relies on air pressure to adjust the ride height and stiffness of the trailer. Air pressure can be controlled manually or automatically using air valves and an air compressor. This allows for quick adjustments based on the load weight and road conditions. 4. Ride Quality: Trailer axle air suspension offers improved ride quality compared to traditional suspension systems. The air springs absorb road shocks and vibrations, resulting in a smoother and more comfortable ride for both the trailer and its cargo. This can help reduce the risk of damage to sensitive or fragile cargo. 5. Leveling and Height Adjustment: Air suspension systems can be equipped with leveling valves that automatically adjust the trailer's ride height to maintain a level position when loading and unloading. This ensures optimal weight distribution and stability. 6. Variable Load Distribution: Trailer axle air suspension allows for dynamic load distribution, where the air pressure in each air spring can be adjusted individually to optimize load distribution across the trailer's axles. This helps improve handling, traction, and overall stability. 7. Maintenance and Service: Regular maintenance of the air suspension system is essential to ensure its optimal performance. This includes checking for air leaks, inspecting air springs for damage, and maintaining proper air pressure levels. It is also important to follow manufacturer guidelines for servicing the system.

EVER-POWER is currently one of the most professional axle manufacturing companies in China, with a factory construction area of 20000 square meters. The company adopts advanced equipment such as electron beam welding machines, arc welding robots, CNC machine tool machining centers, CNC plate welding gantry cutting centers, large hydraulic presses and large cylindrical grinding machines, automatic spraying lines, ultrasonic detectors, coordinate measuring machines, and a series of advanced manufacturing and fatigue testing and inspection equipment. Strictly control the manufacturing of quality standardized production systems. Passing ISO/TS16949 quality inspection certification every year ensures advanced technology, laying a strong foundation for lean production and professional manufacturing.

At present, the mass-produced axles include standard German and American axle assemblies, various types of optical axles, mechanical suspensions, air suspensions, single point suspensions, wheel and brake drum assemblies and their supporting components, European agricultural axle series, front double axle rigid series, torque rocker tube axle series, etc. And can provide professional design customization services. The product is sold to more than 30 countries and regions worldwide. Its product quality and service are highly praised by users.

|

Click here to contact us for more details!

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Our Factory

EVER-POWER is currently one of the most professional axle manufacturing companies in China, with a factory construction area of 20000 square meters. The company adopts advanced equipment such as electron beam welding machines, arc welding robots, CNC machine tool machining centers, CNC plate welding gantry cutting centers, large hydraulic presses and large cylindrical grinding machines, automatic spraying lines, ultrasonic detectors, coordinate measuring machines, and a series of advanced manufacturing and fatigue testing and inspection equipment. Strictly control the manufacturing of quality standardized production systems. Passing ISO/TS16949 quality inspection certification every year ensures advanced technology, laying a strong foundation for lean production and professional manufacturing.

At present, the mass-produced axles include standard German and American axle assemblies, various types of optical axles, mechanical suspensions, air suspensions, single point suspensions, wheel and brake drum assemblies and their supporting components, European agricultural axle series, front double axle rigid series, torque rocker tube axle series, etc. And can provide professional design customization services. The product is sold to more than 30 countries and regions worldwide. Its product quality and service are highly praised by users.

|

Click here to contact us for more details!

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

Our Main procucts

Please click on the photos below to visit their websites.

Hot Searches