- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Keepway

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

1450*650*2600mm

-

Product Name:

-

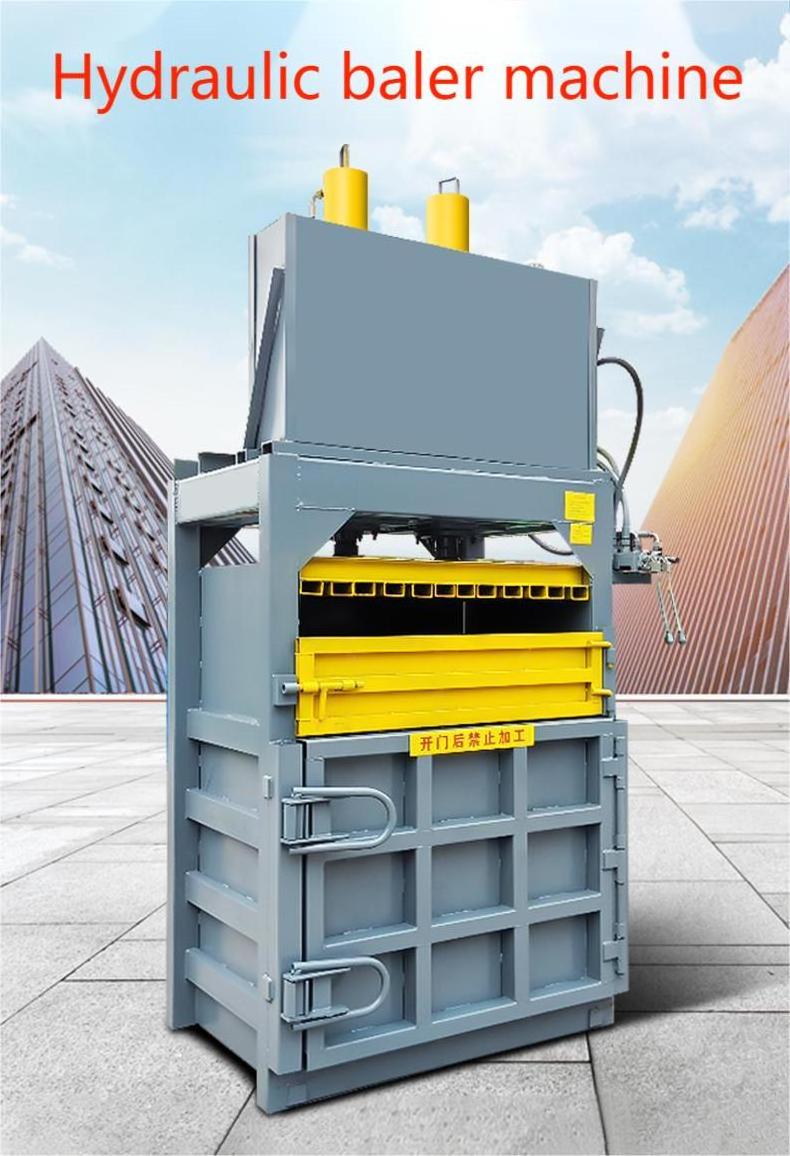

hydraulic baler machine

-

Baler Weight:

-

at least 30-40kgs

-

Baler Size:

-

800*400*800mm(Other sizes can also be customized)

-

Pressure:

-

at least 10 tons

-

Bale Efficiency:

-

4-6 bales/hour

-

Machine Voltage:

-

380/220/440V,3Phases,50/60Hz

-

Raw Material to Bale:

-

clothes, cardboard, film,bottles, cans,cotton, wool,textile,tires

-

After Sales Service:

-

video technical support, online support, Spare parts

-

Certification:

-

ISO9001,CE

-

Suitable for:

-

Cardboard Paper

Quick Details

-

Voltage:

-

380V

-

Power:

-

at least 7.5KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Keepway

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

1450*650*2600mm

-

Product Name:

-

hydraulic baler machine

-

Baler Weight:

-

at least 30-40kgs

-

Baler Size:

-

800*400*800mm(Other sizes can also be customized)

-

Pressure:

-

at least 10 tons

-

Bale Efficiency:

-

4-6 bales/hour

-

Machine Voltage:

-

380/220/440V,3Phases,50/60Hz

-

Raw Material to Bale:

-

clothes, cardboard, film,bottles, cans,cotton, wool,textile,tires

-

After Sales Service:

-

video technical support, online support, Spare parts

-

Certification:

-

ISO9001,CE

-

Suitable for:

-

Cardboard Paper

Products Description

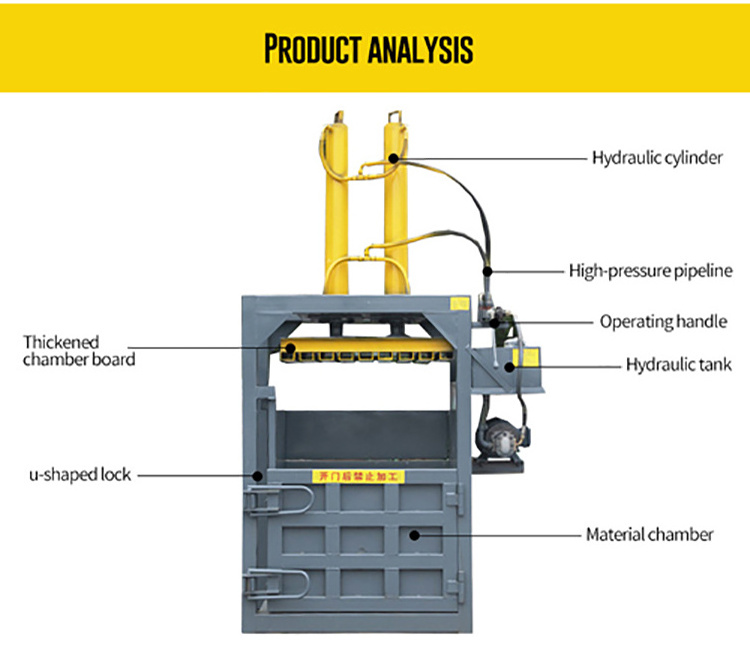

Vertical Hydraulic Baler Baling Press Machine

a: No need to install, simple operation.

b: U-shaped anti-dropping door handle, easy to unlock.

c: Motors adopt brand copper core motors with strong power, durability, faster heat dissipation, and guarantee the machine continues to run smoothly.

d: Automatically turn over the package, push the package to support customized customization, easy to operate, can be directly after the end of the press work machinery out of the package, effectively saving labor.

e: Imported abrasion-resistant and high-sealing oil pipe with thick pipe wall and strong sealing

performance of the connection port to ensure the compression work no oil leaks during operation.

f: Low failure rate and durable.

Product Parameters

|

Type

|

Motor power

(kw)

|

Packing weight

(kgs)

|

Packing size

(mm)

|

Machine size

(mm)

|

Weight

(kgs)

|

|

10 ton

|

7.5

|

30-40

|

800*400*800

|

1450*650*2600

|

650

|

|

20 ton

|

7.5

|

40-80

|

800*400*800

|

1450*650*2700

|

700

|

|

30 ton

|

11

|

80-150

|

1000*600*800

|

1650*850*2700

|

800

|

|

40 ton

|

11

|

150-200

|

1000*600*800

|

1650*850*2750

|

850

|

|

60 ton

|

15

|

250-300

|

1200*800*1000

|

1600*2100*3100

|

1350

|

|

80 ton

|

18.5

|

350-400

|

1200*800*1000

|

1700*2100*3300

|

1550

|

|

100 ton

|

22

|

400-450

|

1200*800*1000

|

1700*2100*3900

|

1650

|

|

120 ton

|

22

|

450-500

|

1100*700

|

1400*2000*4200

|

1750

|

Details Images

More authentic product details

Product Real Pictures

Standard machine in stock

Support customization, welcome to consult

|

FAQ

|

Reason

|

solution

|

|

1.The press block moves up and down unsteadily, with obvious vibration or gaps, and the pressure rises slowly.

|

1.Air in hydraulic system

|

1.Open the bleed valve at the top of the oil cylinder to remove the gas

|

|

1.When shutting down and maintaining pressure, the oil pressure will drop rapidly.

|

1. The sealing ports of the one-way valve and the oil separator of the oil pump are damaged or the hydraulic oil is dirty.

|

1.Depending on the situation, grind the valve port, clean the oil, or replace damaged components of the sealing device, etc.

|

|

|

2. The pump, oil separator and sealing device components in the cylinder are damaged.

|

2.Replacement accessories

|

|

1.The up and down movement of the pressing block is unstable

|

1. After the gear end face is worn, the gap increases and oil leakage is more

|

1. Repair the gear pump and reduce the end clearance.

|

|

|

2. The oil is not clean and the oil filter is clogged.

|

2. Clean the oil filter and clean the working oil.

|

|

1.Hydraulic return stroke is too slow

|

1.The oil is not clean

|

1. Replace with new working fluid.

|

|

|

|

2. Clean the oil filter and clean the working oil.

|

|

1.The hydraulic thrust pressure is not enough.

|

1.There is air in the one-way valve on the oil pump body

|

Slowly loosen the one-way valve to remove the air in the oil

|

More models available

Recommend Products

Customer Photos

Hot Searches