- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 220V Optional

-

Rated Power:

-

50HZ

-

Dimension(L*W*H):

-

customizable

-

Weight (KG):

-

2000 KG

-

Product name:

-

Water Jet Cutters

-

Gantry type:

-

Table

-

Effective Cutting area(Length):

-

1500mm

-

Effective Cutting area(width):

-

3000mm

-

run soeed:

-

0 - 9000mm / min

-

Cutting positioning accuracy:

-

± 0,02 mm

-

Surface roughness:

-

Ra≤25μm

-

Servo motor:

-

Software Supports HPRXD and True Hole

-

Application:

-

Waterjet Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Cutting Accuracy(mm):

-

0.02

-

Brand Name:

-

JUGAO

-

Voltage:

-

380V 220V Optional

-

Rated Power:

-

50HZ

-

Dimension(L*W*H):

-

customizable

-

Weight (KG):

-

2000 KG

-

Product name:

-

Water Jet Cutters

-

Gantry type:

-

Table

-

Effective Cutting area(Length):

-

1500mm

-

Effective Cutting area(width):

-

3000mm

-

run soeed:

-

0 - 9000mm / min

-

Cutting positioning accuracy:

-

± 0,02 mm

-

Surface roughness:

-

Ra≤25μm

-

Servo motor:

-

Software Supports HPRXD and True Hole

-

Application:

-

Waterjet Machine

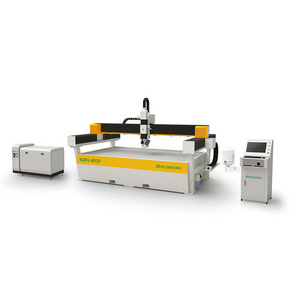

5 Axis Water jet Cutter 3D Waterjet Cutting Machine With Flow Type Direct Drive Pump Water Jet Machine

Performance characteristics

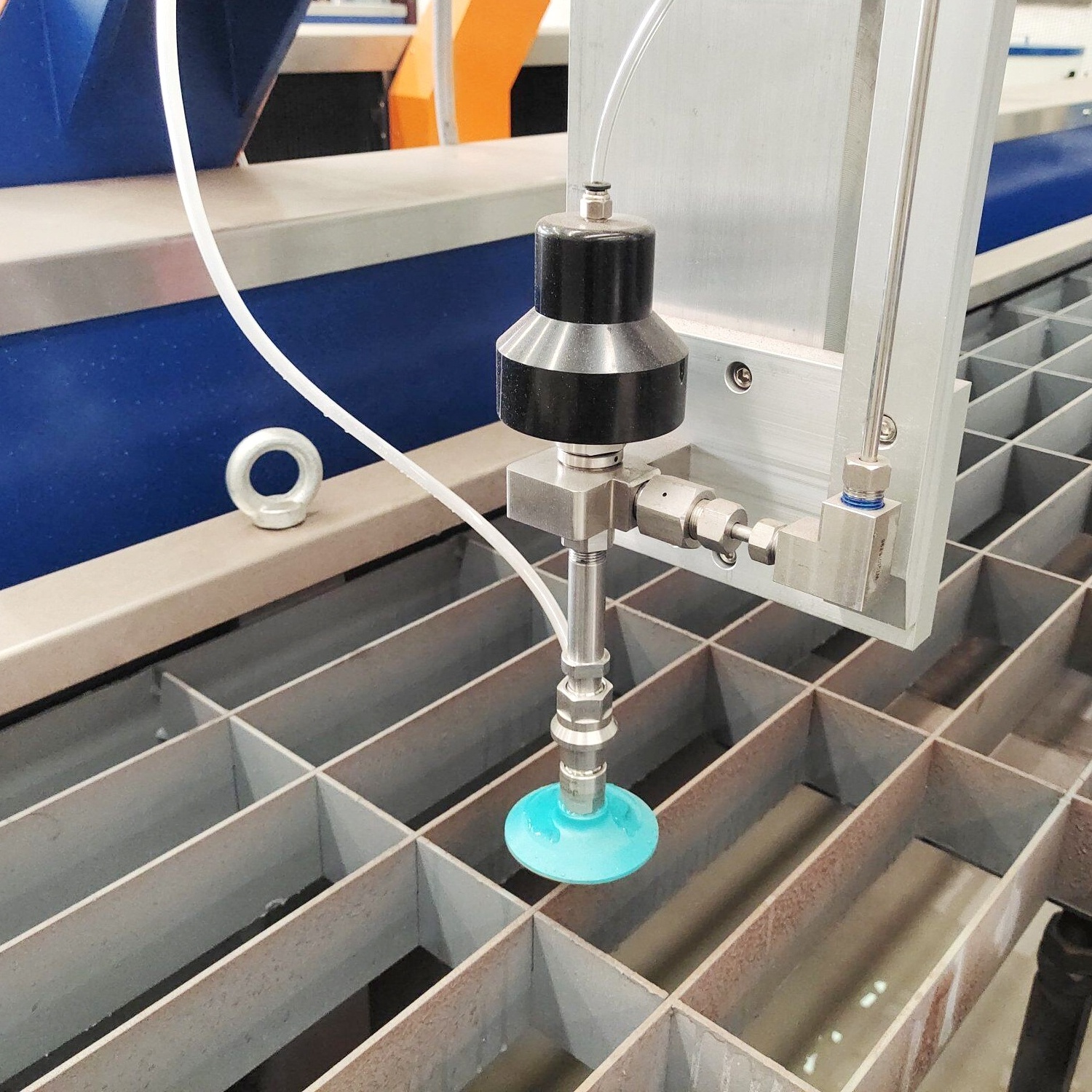

Monoblock Design Waterjet Cutting Machine, Any material can be cut at one time for any curve (except water cutting, other cutting methods will be limited by the material variety); The heat generated during cutting will be immediately taken away by the high-speed flowing water jet, and no harmful substances will be produced. The material has no thermal effect (cold cutting). After cutting, it does not need or is easy for secondary processing. It is safe, environmentally friendly, fast and efficient. It can realize the cutting of arbitrary curves, convenient, flexible and widely used. Water cutting is a mature cutting process with good applicability.

# The whole processing, the water tank guide surface is formed in one time,and the geometric accuracy of the machine is fully guaranteed, including parallel and ascending.It Will meet the highest requirements,and the equipment will be more stable for long-term use.

# Easy installation,saving assembly time and after-sales service.

# Use absolute servo motor and LED warning light.

# To ensure waterjet accuracy, cutting table frame is treated in overall heat treatment and stress relief treatment, it is never deformed.

# Robust and accurate design for tight tolerance cutting and reliable operation.Fastest cutting speeds and best precision compared to any competitive abrasive water jet in the industry.

Cutting sample display

Technical parameter

| Net Cutting Area |

X = 2.000 mm (6.56')

Y = 1.500 mm (4.92' ) Z = 150 mm (5.9") |

| Inner Table Working Area |

2.000 mm x 1.500 mm

(6.56' x 4.92') |

| Overall Dimensions |

2.200 mm x 1.700 mm

(7.22' x 5.58' ) |

| Rapid Speed |

0 - 9000mm / min

(0-29.53' / min) |

| Weight |

2.000 Kg

(5.000 lb) |

| Positioning Accuracy |

± 0,02 mm

(± 0,0008") |

| Repeatability |

± 0,01 mm

(± 0,003") |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.