- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.8*1.4*1.4m

-

Weight:

-

4500 kg

-

Feeding width:

-

914-1450mm

-

Product name:

-

Roof Sheet Forming Machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45# Steel Plated

-

Control system:

-

PLC

-

Cutting type:

-

Hydraulic Cutting

-

Frame:

-

H beam or U channel

-

Cutting blade material:

-

Cr12 Quenched

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-35m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5.8*1.4*1.4m

-

Weight:

-

4500 kg

-

Feeding width:

-

914-1450mm

-

Product name:

-

Roof Sheet Forming Machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45# Steel Plated

-

Control system:

-

PLC

-

Cutting type:

-

Hydraulic Cutting

-

Frame:

-

H beam or U channel

-

Cutting blade material:

-

Cr12 Quenched

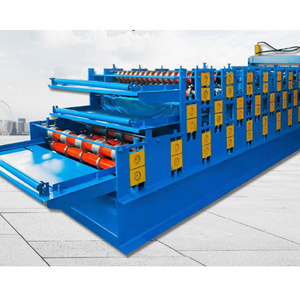

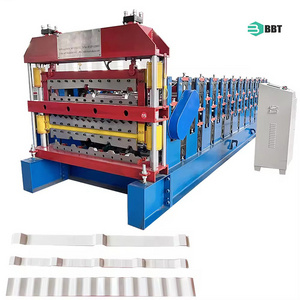

Product Overview

Tile/Roof Roll Forming Machine

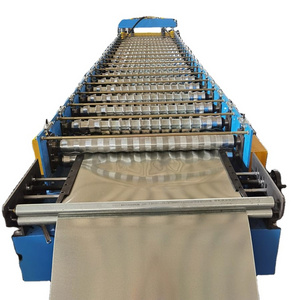

The machine is composed of the Frame, PLC control system, hydraulic station, and automatic shearing system.

The tile/roof produced are flat and beautiful in appearance, uniform in paint pattern, and are widely used in industrial and civil buildings, such as houses, warehouses, garages, hangars, gymnasiums, exhibition halls, theaters and other room surfaces and walls.

FEATURES AT A GLANCE

The machine adopts high-level automatic control software to realize production information management. The whole unit automation control system adopts a highly integrated network, which makes the automation system have superior performance.

It also has the advantages of easy operation, easy maintenance and debugging, and easy mold replacement.

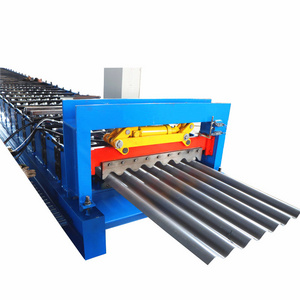

PRODUCTION PROCESS

Decoiler--Feeding--Forming--Cutting--Receiving

PRODUCT SPECIFICATIONS

|

Suitable to process

|

Color steel plate

|

|

Width of the plate

|

1219mm

|

|

Material of the cutting plate

|

Cr12

|

|

Productivity

|

8-10m/min

|

APPLICATION

PACKING

roof tile roll forming machine

standard wooden case for export 20ft container or 40ft container

COMPANY PROFILE

We,

Tangshan Shuoen

is a professional cold roll forming machine manufacturer, We have been focusing on this field for 10 years. Our equipment includes roof roll forming machine, floor deck roll forming machine, automatic decoiler, light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment.Shuoen has employed a team of engineers for more than 10 years. At the same time, our machines use branded electrical components, raw materials from branded steel factories, strict process control, two-year warranty, installation and training services.Our customers are all over the world, such as 65 countries in Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other different regions. We have extensive experience in the needs of different countries, such as profile, thickness range, use, installation, etc.Thank you for your trust and choice, we will provide you with the best service support and help you achieve greater success.Looking forward to more cooperation with new and old friends from all over the world.

FAQ

Q: If you can customized the glazed tiles forming machine for i need?

A: Yes, Just share your design to us is ok, we will give you one fully quotations.

Q: About the voltage, if ok 380v/50hz ?

A: Yes, we can customized the voltage to you.

Q: If the price include the delivery fee?

A: No, the price not include, usually the web show, it is exw price, if you want we help you delivery, pls share your nearest seaport to us is ok.

A: Yes, Just share your design to us is ok, we will give you one fully quotations.

Q: About the voltage, if ok 380v/50hz ?

A: Yes, we can customized the voltage to you.

Q: If the price include the delivery fee?

A: No, the price not include, usually the web show, it is exw price, if you want we help you delivery, pls share your nearest seaport to us is ok.

Hot Searches