- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1400 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YETO

-

Voltage:

-

AC 220V/380V

-

Power (kW):

-

35 kW

-

Product name:

-

steam heating emulsifying homogenizer mixer tank

-

Usage:

-

cosmetic cream lotion mixer manufacturing machinery

-

Machine Type:

-

heating blender homogenizer mixer

-

Heating method:

-

Electric Heating

-

Capacity:

-

100-1000L

-

Keyword:

-

liquid soap detergent hand sanitizer mixing making machine

-

Machine Name:

-

heating emulsifier mixer with agitator

-

Application scope:

-

High Viscosity cream lotion paste liquids

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

1000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 2880 r.p.m

-

Weight (KG):

-

1400 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YETO

-

Voltage:

-

AC 220V/380V

-

Power (kW):

-

35 kW

-

Product name:

-

steam heating emulsifying homogenizer mixer tank

-

Usage:

-

cosmetic cream lotion mixer manufacturing machinery

-

Machine Type:

-

heating blender homogenizer mixer

-

Heating method:

-

Electric Heating

-

Capacity:

-

100-1000L

-

Keyword:

-

liquid soap detergent hand sanitizer mixing making machine

-

Machine Name:

-

heating emulsifier mixer with agitator

-

Application scope:

-

High Viscosity cream lotion paste liquids

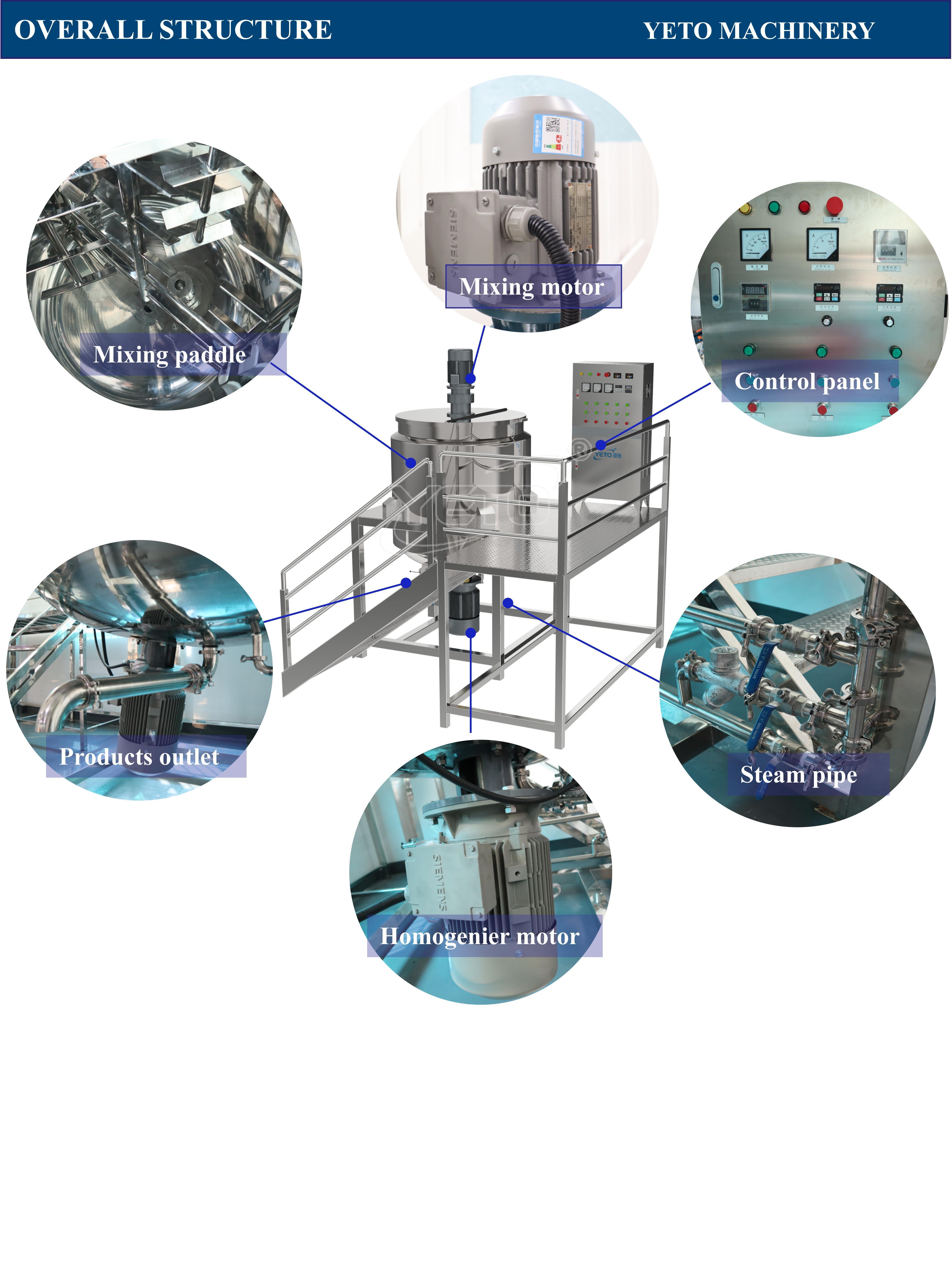

Product Overview

YETO 1000L homogenizer Mixer with Agitator tank for making liquid soap shampoo lotion gel electric heating mixing machine

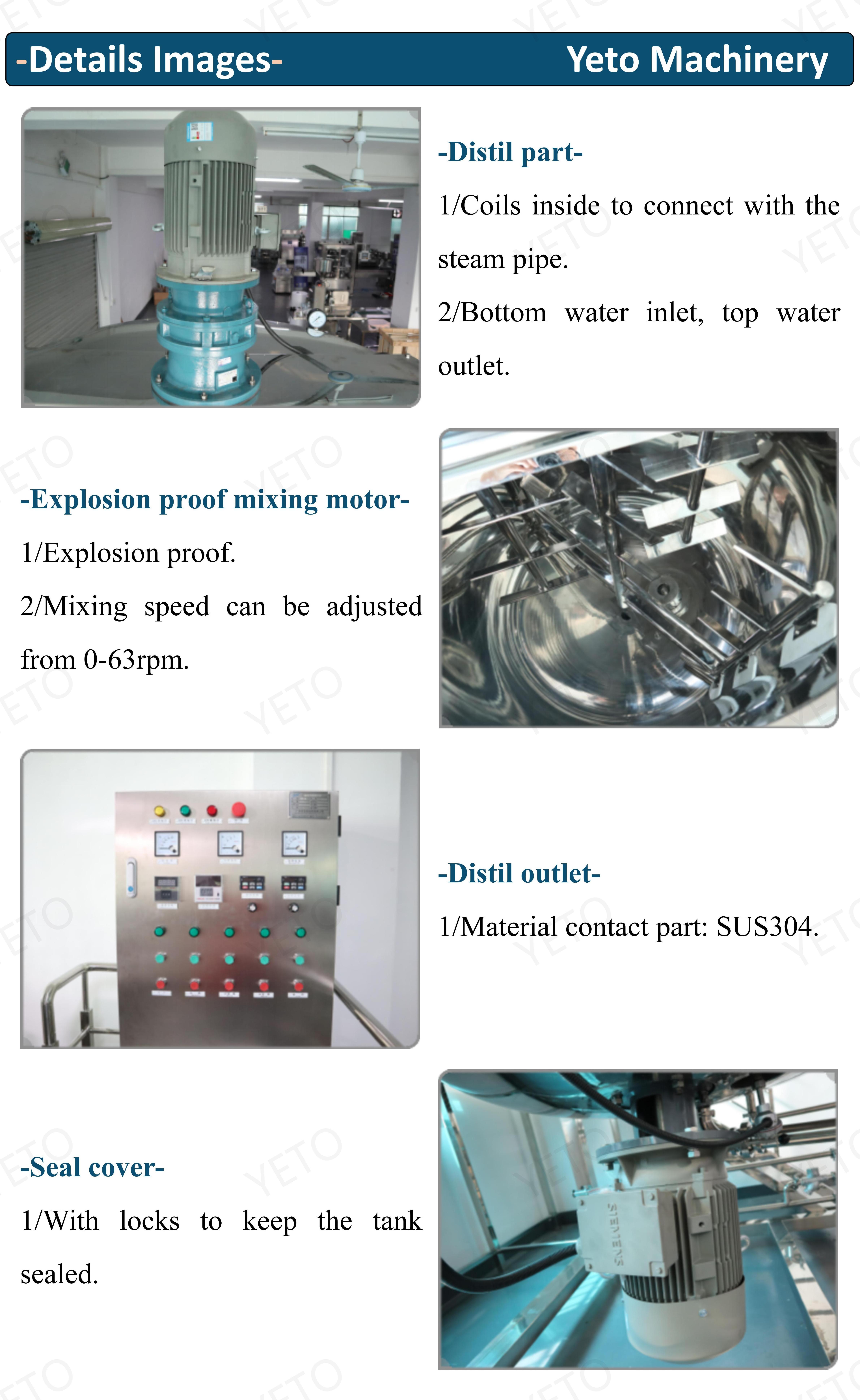

This mixing tank consist of homogenizer mixer pot , heating pipe, control cabinet and platform.

Mixer pot

is made of

three layers stainless steel and double jackets

. The inner layer is

SUS316L

, Top frame mixer and bottom homogenizer can emulsify and mix the products into smaller molecules to achieve the perfect high quality products.

Heating by

steam system

, decrease the heating time and increase the working efficiency.

|

Item

|

Data

|

|

voltage

|

AC 380V, 3phase

|

|

mixing type

|

Frame scrapper mixer and high shear homogenizer

|

|

Heating method

|

steam heating

|

|

Working capacity

|

300-1000L

|

|

Tank structure

|

Three layers, doubles jacket

|

|

Material

|

SUS316L/304

|

|

Discharge outlet

|

bottom discharge butterfly valve

|

|

Motor

|

Siemens , ABB is optional

|

Details Images

Packing and shipping

PRODUCT SPECIFICATIONS

FAQ

1. What about your factory?

One of our factory is located in Guangzhou and another one is in Jiangsu province. We have more than 100 workers in our factory ,over 20 years experience on cosmetic machinery making and more 15 years experience for installing overseas.

2.What you can do for us if the machine is out of your catalogue?

As a professional machinery manufacturer for more than 20 years,we have skilled OEM technique.

3.What do we do if we encounter problem about the machine ?

Showing us the picture or video of the problem. If the problem can be solved by your workers, we will send you solution by video or pictures. If the problem out of your control, our engineer will be sent to your factory (customer will pay the fee during the trip).

4. What about after sale service?

We provide two years warranty period for large equipment, such as hydraulic homogenizer ,vacuum emulsifying mixer etc. One year for small filling machines, such as semi-automatic labeling machine series. We provide wearing parts(not caused by improper operating) for free within the warranty period(except delivery fee).

5.How about warranty and spare parts?

We provide 1-3 years warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that we provided are finished.

6 How to finish installing?

Our engineer can be sent to your country. but customer should pay the air tickets. besides, customer should arrange the

accommodation for them during the trip.

7. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

One of our factory is located in Guangzhou and another one is in Jiangsu province. We have more than 100 workers in our factory ,over 20 years experience on cosmetic machinery making and more 15 years experience for installing overseas.

2.What you can do for us if the machine is out of your catalogue?

As a professional machinery manufacturer for more than 20 years,we have skilled OEM technique.

3.What do we do if we encounter problem about the machine ?

Showing us the picture or video of the problem. If the problem can be solved by your workers, we will send you solution by video or pictures. If the problem out of your control, our engineer will be sent to your factory (customer will pay the fee during the trip).

4. What about after sale service?

We provide two years warranty period for large equipment, such as hydraulic homogenizer ,vacuum emulsifying mixer etc. One year for small filling machines, such as semi-automatic labeling machine series. We provide wearing parts(not caused by improper operating) for free within the warranty period(except delivery fee).

5.How about warranty and spare parts?

We provide 1-3 years warranty and enough spare parts for the machine,and most of the parts can be found in local market also,also you can buy from us if all the parts that we provided are finished.

6 How to finish installing?

Our engineer can be sent to your country. but customer should pay the air tickets. besides, customer should arrange the

accommodation for them during the trip.

7. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

Hot Searches