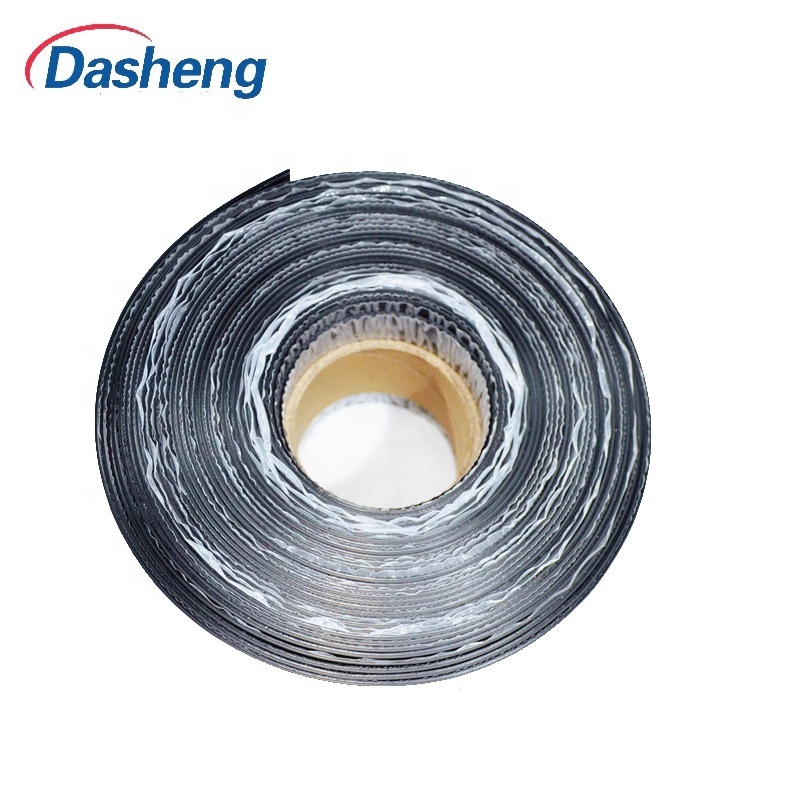

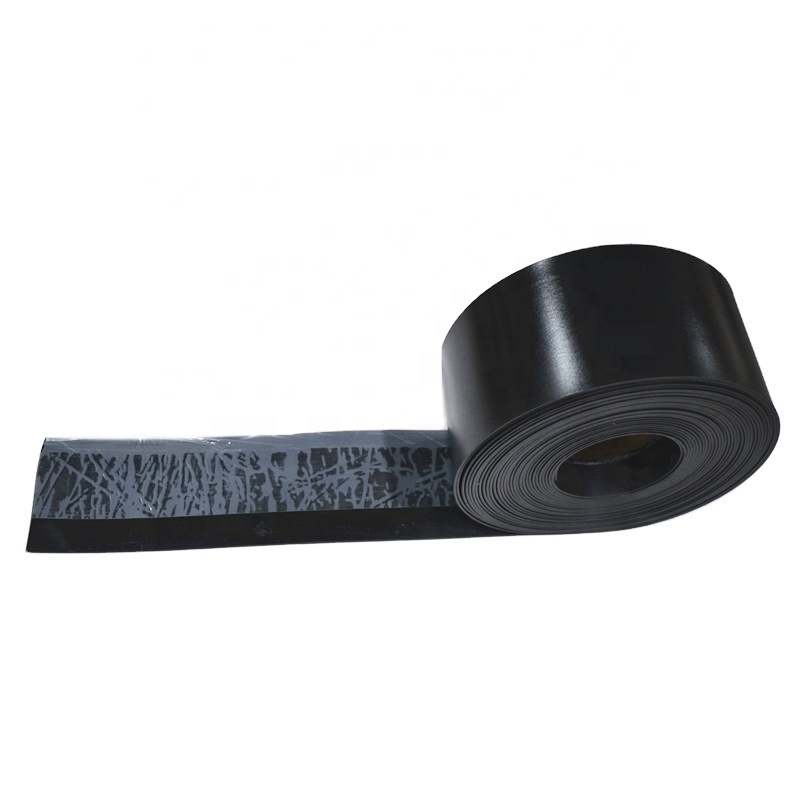

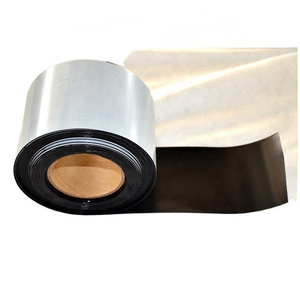

WT heat shrinkable wraparound tape is designed for corrosion protection of field girth weld joint of buried and exposed steel pipelines,also for pipe bends or pipe elbow.WT consists of a radiation crosslinked low density polyethylene backing,coated with a hot sensitive adhesive which effectively bonds to steel substrates and common pipelines coatings,including polyethylene and fusion bonded epoxy.WT can be conveniently used for corrosion protection of steel pipe,especially for protection and repairing pipelines,fittings,elbows,bends and other irregular configurations.

- Product Details

- {{item.text}}

Quick Details

-

Tensile Strength:

-

10.4Mpa

-

Color:

-

Black

-

Usage:

-

corrosion protection of field weld joint of buried

-

Function:

-

corrosion protection

-

Backing thichness:

-

1.0~2.0mm

-

Adhesive thichness:

-

0.8~2.00mm

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

dasheng

-

Model Number:

-

DS-CRD

-

Tensile Strength:

-

10.4Mpa

-

Color:

-

Black

-

Usage:

-

corrosion protection of field weld joint of buried

-

Function:

-

corrosion protection

-

Backing thichness:

-

1.0~2.0mm

-

Adhesive thichness:

-

0.8~2.00mm

Pipes Anti-corrosion PE backing Duct Tape Heat Shrink

Wrapping Heat Shrinkable Tape

WT provides excellent resistance to cathodic disbandment resulting in effective long-term corrosion protection.The high performance crosslinked backing in combination with a broad of adhesive can be undertaken for regular or high stress environments.Upon the application of heat,wrap around tape shrinks down to fully encapsulate the protected substrate,the hot melting adhesive flows into all surface irregularities,forming a protective barrier against corrosion.

|

Product selection guide:

|

|

|

|

|

||||

|

|

TS 60

|

TS50 (mastic)

|

TS 60

|

TS 80

|

||||

|

Max operating temperature

|

|

60ºC

|

70ºC

|

85ºC

|

||||

|

Compatible line coatings

|

|

PE, FBE, PP

|

PE, FBE, PP

|

PE, FBE, PP

|

||||

|

Preheat temperature

|

|

60ºC

|

70ºC

|

85ºC

|

||||

|

Recommended pipe preparation

|

|

Clean, dry and free of grease

|

Clean, dry and free of grease

|

Clean, dry and free of grease

|

||||

|

Performance

|

|

SY/T0413-2002 EN12008

|

SY/T0413-2002 EN12008

|

SY/T0413-2002 EN12008

|

||||

|

Property

|

Test Method

|

TS 60

|

|

Operating Temperature

|

|

Up to 60°C

|

|

Tensile Strength

|

ASTM D638

|

3000 psi

|

|

Elongation

|

ASTM D638

|

600%

|

|

Hardness ShoreD

|

ASTM D2240

|

50

|

|

Dielectric Strength

|

ASTM D149

|

20KV/mm

|

|

Volume resistivity

|

ASTM D257

|

1x 1016 Ω-cm

|

|

Water Absorption

|

ASTM D570

|

<0.05%(wt)

|

|

Softening Point

|

ASTM E28

|

103°C

|

|

Lap Shear

|

ASTM D1002

|

300 N/cm2@23°C

|

|

Peel Strength

|

DIN EN 12068

|

60 N/cm@23°C

|

|

Impact Resistance

|

DIN EN 12068

|

>15J

|

RANGE:

Standard manufacturing range covers the following sizes and dimensions:

The heat shrinkable tape width: 50mm, 100mm, 150mm, 200mm, 250mm, 300mm

The tape total thickness: 1.8mm, 2.0mm, 2.2mm, 2.3mm, 2.5mm

Dasheng is synonymous with high customer satisfaction, reliability of supply and consistency of quality. We are dealing primarily in heat shrinkable sleeve, tape and tubing. Everything we manufacture is custom to customer's exact specifications. Our outgoing success is deeply rooted in the qualifications and professionalism of our employees. Our 700 people, including 150 engineers, partner with customer across a wide of industries. Turning problems into solutions is just one way we can make the world a better place.