- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NanXiang

-

Product name:

-

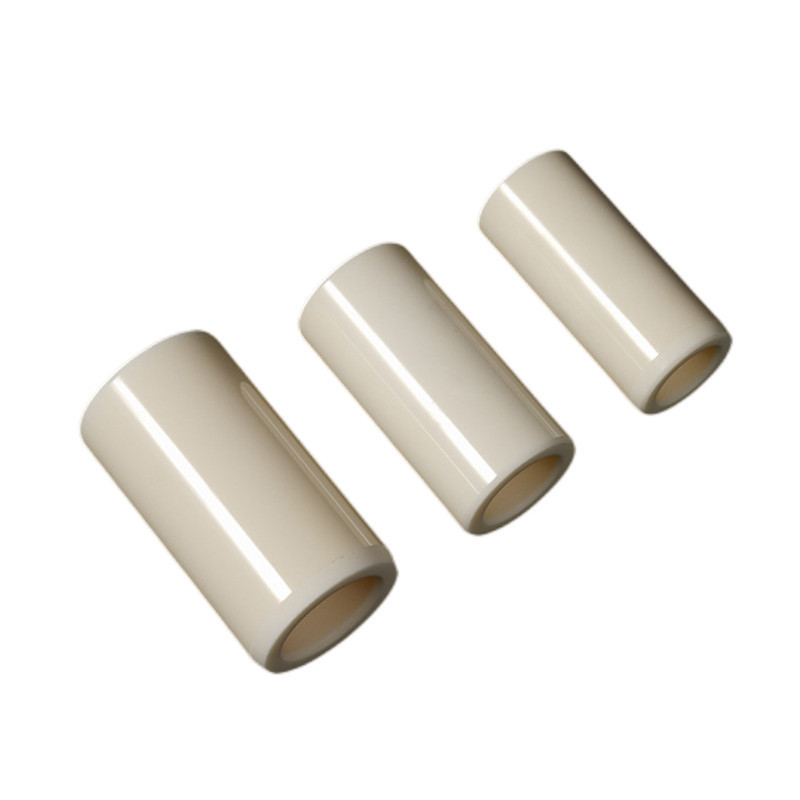

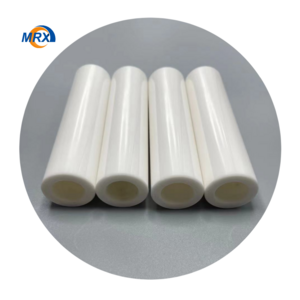

High Pressure Insulation Spare Part Alumina Ceramic Piston Plunger

-

Keywords:

-

Alumina Ceramic Piston Plunger

-

Max Working Temperature:

-

1650°C /1700°C

-

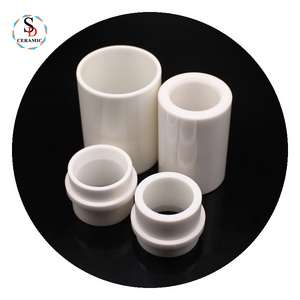

Color:

-

White&Light Yellow

-

Fit Tolerance:

-

+-0.005mm

-

Density:

-

3.6g/cm3

-

Usage:

-

Wear-resisting Material

-

Feature:

-

High Wear-resistance,High Temperature Resistance

-

MOQ:

-

10pcs

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Model Number:

-

NX-CPP007

-

Brand Name:

-

NanXiang

-

Product name:

-

High Pressure Insulation Spare Part Alumina Ceramic Piston Plunger

-

Keywords:

-

Alumina Ceramic Piston Plunger

-

Max Working Temperature:

-

1650°C /1700°C

-

Color:

-

White&Light Yellow

-

Fit Tolerance:

-

+-0.005mm

-

Density:

-

3.6g/cm3

-

Usage:

-

Wear-resisting Material

-

Feature:

-

High Wear-resistance,High Temperature Resistance

-

MOQ:

-

10pcs

Video Presentation

Products Description

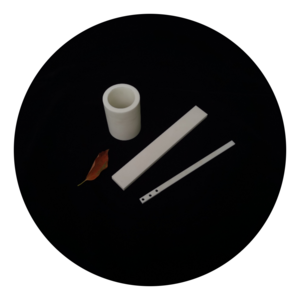

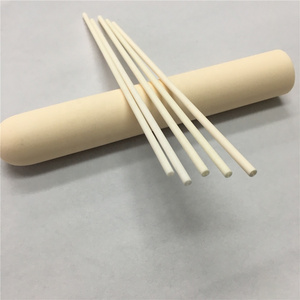

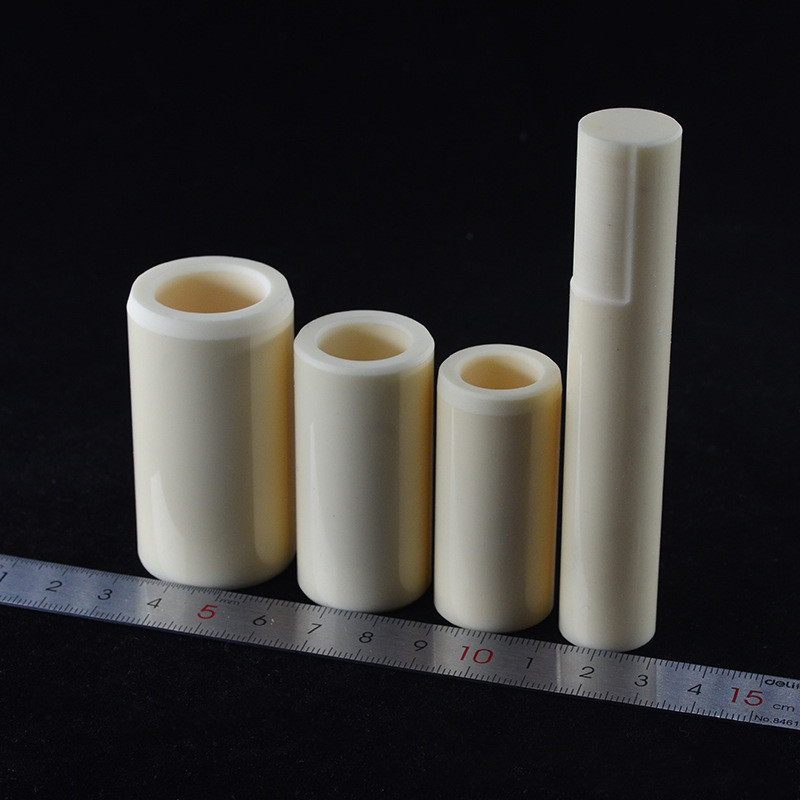

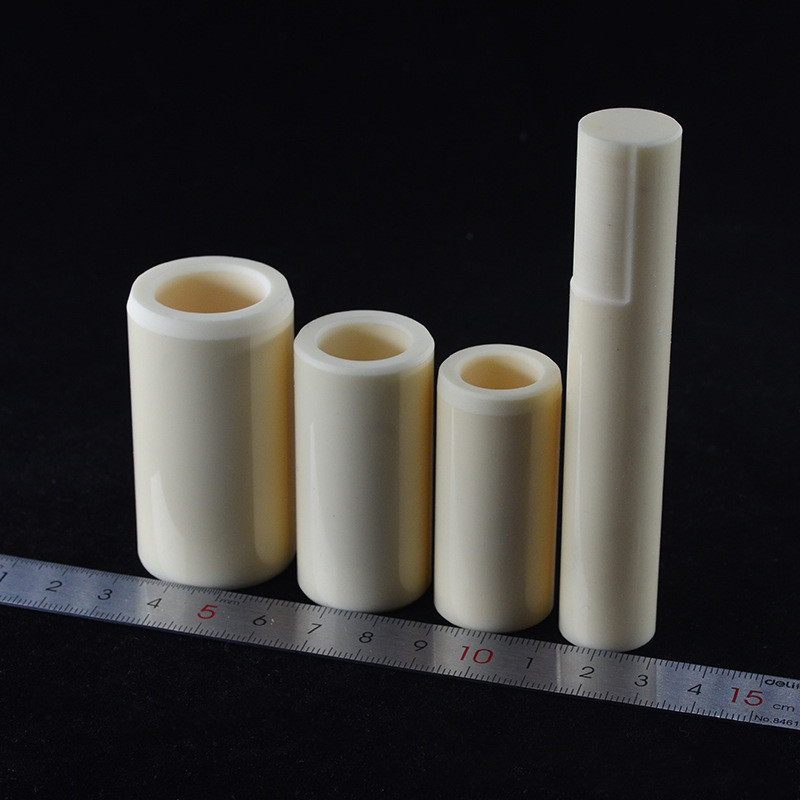

High Pressure Insulation Spare Part 99.5% Alumina Ceramic Piston Plunger

insulation,resistant acid-base,high intensity,thermostable,high temperature tolerance,good insulation,high strength,precision process,high mechanical strength,good chemical stability.

Good smoothness, mechanical seal good, polishing surface and so on.

2. Forming methods includes:

Drying pressing

Isostatic pressing

Hot pressing casting

3. The application of our product:

Ceramic shaft,sleeve for different pump.

Ceramic plunger for high pressure cleaner.

Wearlessness,resistant acid-base and high intensity ceramic assembly apply to petroleum,chemical industry.

Wearlesness,corrosion resistance,thermos table parts apply to precision machine.

4. Features:

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

|

Item

|

Unit

|

95% Al2O3

|

99% Al2O3

|

|

Heat Resistance

|

℃

|

1500

|

1800

|

|

Bulk Density

|

g/cm3

|

3.6

|

3.8

|

|

Water Absorption

|

%

|

0

|

0

|

|

Flexural Strength

|

Mpa

|

320

|

360

|

|

Hardness Vickers

|

Gpa

|

12.2

|

15.6

|

|

Elastic Modulus

|

Gpa

|

280

|

370

|

|

Poisson’s Ratio

|

--

|

0.22

|

0.23

|

|

Linear Expansion Coefficient

|

(20-5000℃) 10-6/℃

|

7.1

|

8

|

|

Thermal Conductivity

|

W/(M.K)

|

16

|

32

|

|

Specific Heat

|

×10-3J/(KG.K)

|

0.78

|

0.9

|

|

Dielectric Constant(1MHZ)

|

--

|

9

|

9.9

|

|

Dielectric Loss Angle

|

×10-4

|

15

|

1

|

|

Dielectric Strength

|

×106V/m

|

12

|

15

|

Details Images

Packing & Shipping

Jumbo Bag Packaging

Kraft Paper Drum Packaging

Wooden Case Packaging

Woven Bag Packaging

Hot Searches