- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

IPANDA

-

Dimension(L*W*H):

-

2300(L)x1500(W)x1900(H)mm

-

Weight:

-

500 KG

-

Name:

-

Chili Sauce Bottle Filling Capping Labeling Machine

-

Material:

-

SUS304/316

-

After-sale service:

-

Engineers available to service machinery overseas

-

Filling volume:

-

200-800ml(customize)

-

Apllication:

-

Honey,Jam,Jucie.etc.

-

Capacity:

-

1000-3000bph(customize)

Quick Details

-

Machinery Capacity:

-

4000BPH, 6000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

sauce, paste

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

IPANDA

-

Dimension(L*W*H):

-

2300(L)x1500(W)x1900(H)mm

-

Weight:

-

500 KG

-

Name:

-

Chili Sauce Bottle Filling Capping Labeling Machine

-

Material:

-

SUS304/316

-

After-sale service:

-

Engineers available to service machinery overseas

-

Filling volume:

-

200-800ml(customize)

-

Apllication:

-

Honey,Jam,Jucie.etc.

-

Capacity:

-

1000-3000bph(customize)

Product Description

The machine is suitable for the quantitative filling of various kinds of sauces such as

tomato sauce, chili sauce,

fruit jam,

high concentration and containing pulp or granule beverage, even pure liquid. This machine adopts the principle of upside down piston filling. The piston is driven by the upper cam. The piston and piston cylinder are specially treated. With precision and durability, it is an ideal choice for many food seasoning manufacturers.

Features:

1. Filling valve can be customized according to customer’s materials to meet the filling requirements of different customer materials.

2. The tomato Sauce Paste filling machine equipped with horizontal mixing hopper, the maximum guarantee of uniform material in the filling process, no oil ketchup separation, to ensure the accuracy of each bottle filling.

3. The equipment greatly shortens the filling distance from the hopper to the filling head in design, and overcomes the material with large oil content (such as: chili oil containing sesame seeds).

2. The tomato Sauce Paste filling machine equipped with horizontal mixing hopper, the maximum guarantee of uniform material in the filling process, no oil ketchup separation, to ensure the accuracy of each bottle filling.

3. The equipment greatly shortens the filling distance from the hopper to the filling head in design, and overcomes the material with large oil content (such as: chili oil containing sesame seeds).

4. Material contact parts are made of stainless steel, easy to disassemble and assemble, easy to clean and meet the requirements of GMP.

5. Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

5. Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

6. With no bottle no filling function, liquid level automatic control feeding.

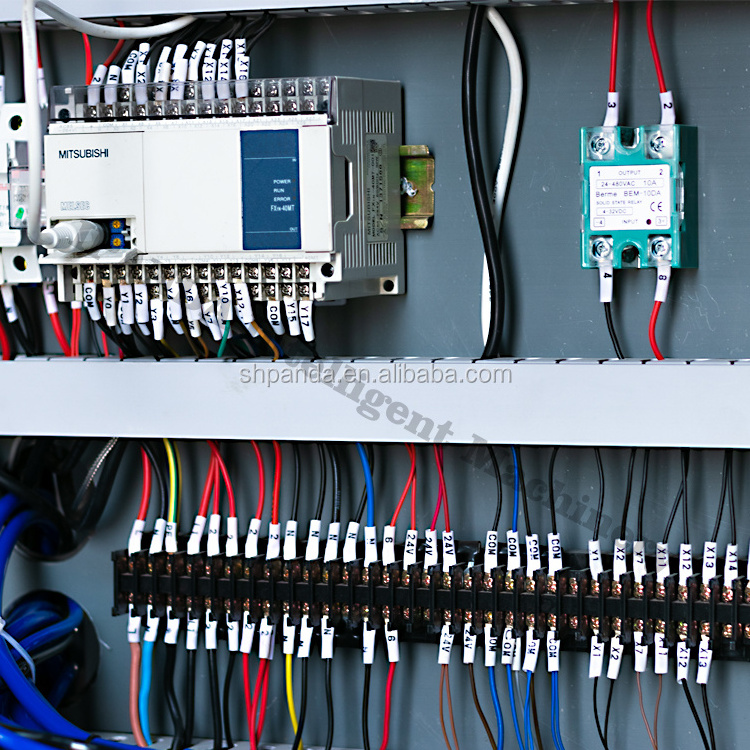

PLC Electric Cabinet

This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

HMI Operation Interface

Mitsubishi electronically controlled PLC touch screen

Electric eye

The electric eye uses advanced photo-electricity.

Easy adjust the position and angle,fast and stable.

Adopt SS304 or SUS316 filling heads

Adopt SS304 or SUS316 filling heads,Especially design anti-leak filling head, No bottle no filling.

Piston pump control filling head

Ensure the filling volume accuracy. The height of filling head can be adjusted through the adjust handle, the filling head can suitable different height and volume bottles. Filling volume can adjust according to customer's reuqirments. No bottle no filling.

Product Paramenters

|

Filling nozzle number

|

2/4/6/8/12

|

|

|

Filling volume

|

100-1000ml (accepted customized)

|

|

|

Production capacity

|

15-100bottles/min

|

|

|

Filling accuracy

|

±≤1%

|

|

|

Capping rate

|

≥98%

|

|

|

Air supply

|

0.4-0.7, Mpa

|

|

|

Voltage

|

220V, 50Hz or 60Hz

|

|

|

Power supply

|

3.5KW

|

|

|

Machine net weight

|

600kg(accepted customized)

|

|

|

Machine dimension

|

5800*1500*1800mm

|

|

|

|

||

Accessory brand

|

Machine frame

|

SUS304 Stainless steel

|

|

|

|

The parts which contact liquid

|

SUS316L Stainless steel

|

|

|

|

Inverter

|

Mitsubishi

|

Japan

|

|

|

Air Switch

|

Schneider

|

France

|

|

|

Contactor

|

Schneider

|

France

|

|

|

Relay

|

Omron

|

Japan

|

|

|

OFA

|

Autonics

|

Korea

|

|

|

Bearing

|

IGUS

|

Germany

|

|

|

Turntable

|

Plastic POM

|

Japan

|

|

|

Cylinder

|

AIRTAC

|

Taiwan

|

|

|

Touch screen

|

Siemens

|

Germany

|

|

|

PLC

|

Siemens

|

Germany

|

|

|

Servo motor

|

Delta

|

Taiwan

|

|

Related Products

Hot Searches