- Product Details

- {{item.text}}

Quick Details

-

Material:

-

steel/carbon steel/alloy steel, 20crmoti, alloy steel

-

Torque Capacity:

-

OEM

-

Model Number:

-

customizable

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MSMT

-

Name:

-

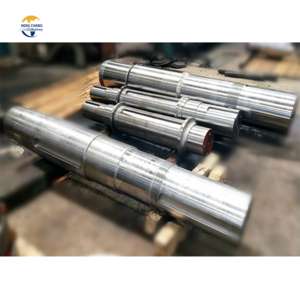

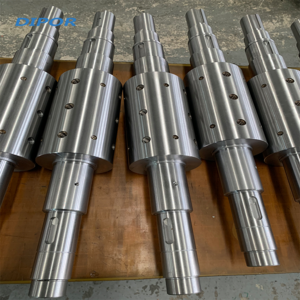

cold rolling mill roller shaft

-

Quality:

-

High Precision

-

Process:

-

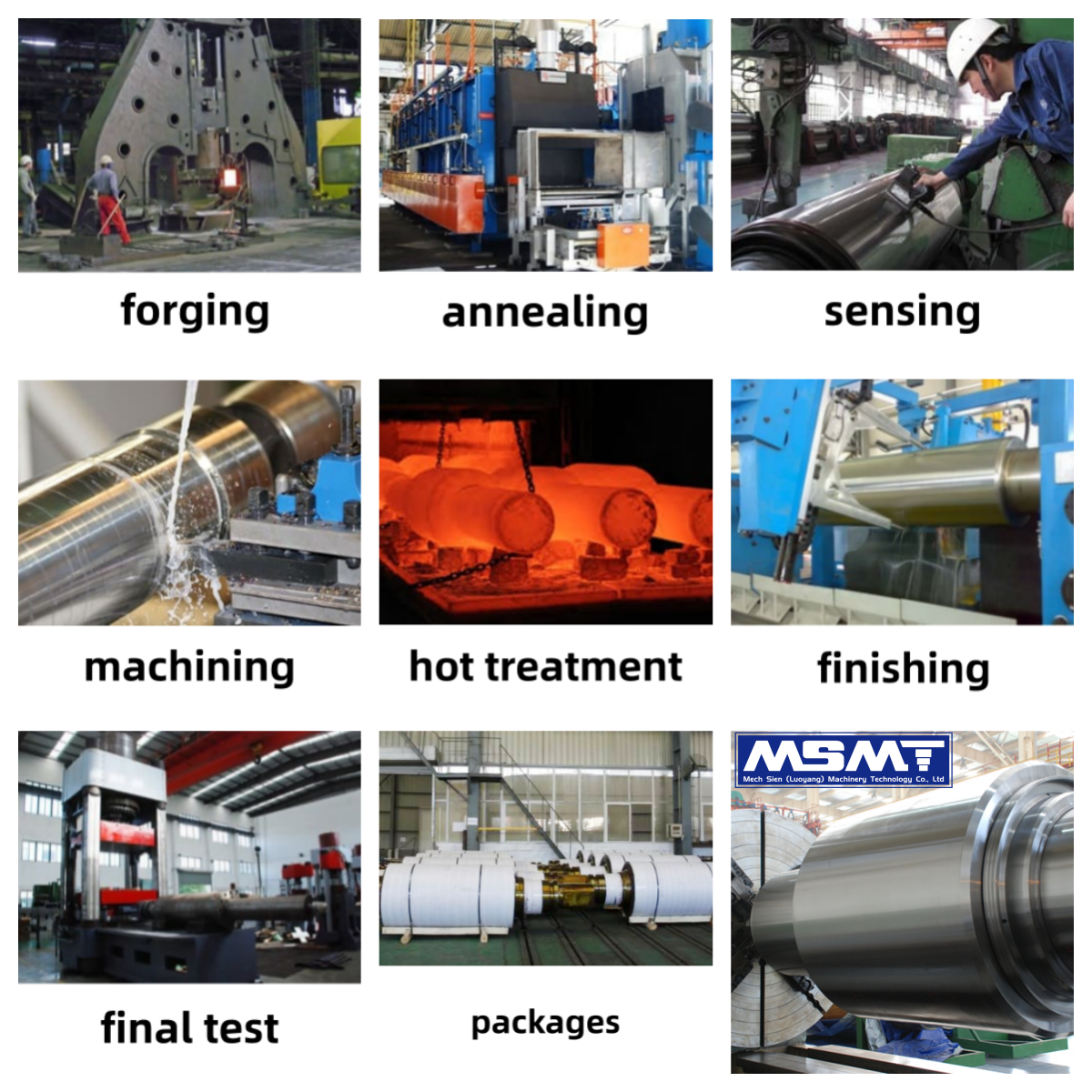

Forging , Machining , Heat Treatment

-

Heat treatment:

-

Quenching and tempering

-

appliance:

-

Industrial equipment

-

Tolerance:

-

0.01mm

Quick Details

-

Weight (KG):

-

1500

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

Gear shaft

-

Material:

-

steel/carbon steel/alloy steel, 20crmoti, alloy steel

-

Torque Capacity:

-

OEM

-

Model Number:

-

customizable

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MSMT

-

Name:

-

cold rolling mill roller shaft

-

Quality:

-

High Precision

-

Process:

-

Forging , Machining , Heat Treatment

-

Heat treatment:

-

Quenching and tempering

-

appliance:

-

Industrial equipment

-

Tolerance:

-

0.01mm

Details Images

The gear shaft as a whole is made of high-quality steel, not easy to rust, smooth appearance, turning, grinding and other professional production production process, one-piece molding, stable structure, focusing on every detail of the product, and make every effort to create high-precision, high-hardness, high quality products, this product is widely used in a wide range of products.

|

Product name

|

|

cold rolling mill roller shaft

|

|

||

|

Heat treatment

|

|

Normalizing,Annealing,Quenching&Tempering,SurfaceQuenching,Case hardening

|

|

||

|

Surface treatment

|

|

quenching and tempering+quenching

|

|

||

|

Process

|

|

Forging, Machining, Heat Treatment

|

|

||

|

|

|

large printing machine,airplanes,production machinery, port industry, heavy industry machinery,etc

|

|

||

|

Processing material

|

|

42 CrMo, 40CrNiMo,40Cr、40CrNi 20GrMnTi carburizing and quenching, etc. The surface roughness can reach 0.8.The hardness of the

shaft can reach HRC60, and non-standard customized services can also be provided. |

|

||

|

Product specification

|

|

capable of producing various forgings with diameter of 100mm-6000mm

|

|

||

|

Processing method

|

|

turning, milling, planing, grinding, drilling, etc

|

|

||

|

Technical parameters

|

|

according to relevant standards or drawings and requirements provided by customers

|

|

||

|

Product advantage

|

|

1.Heavy load capacity,long lifespan.

2.High precision,large diameter and module . 3.stable transmission, low impact, vibration and noise |

|

||

Production Technology

Our Advantages

Mech Sien (Luoyang) Machinery Technology Co., Ltd

We have complete processing equipment, including horizontal lathes, vertical lathes, CNC boring and milling machines, CNC boring

machines, deep hole drilling and boring machines, gear hobbing machines, gear grinding machines, etc.

machines, deep hole drilling and boring machines, gear hobbing machines, gear grinding machines, etc.

APPLICATION

Hot Searches