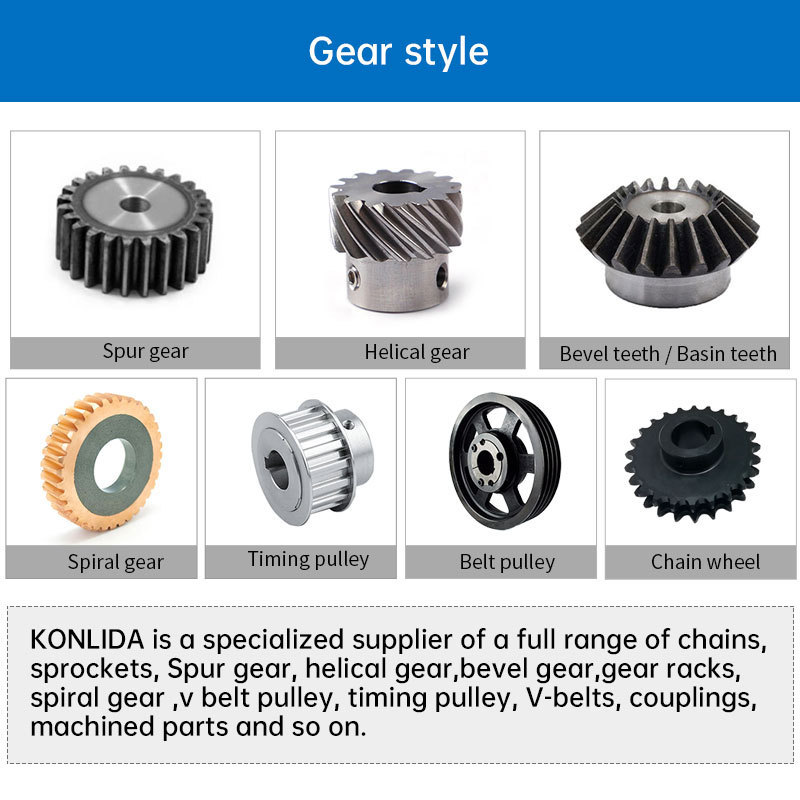

Heavy Machinery Gear Box M2.5 Cnc Rack K Series Bevel Pinion 1,25 Small 45 Degree Wheel Helical Gear

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Wide Varieties Metal Sintering Helical Gear

-

Surface treatment:

-

carbonization, case hardenning

-

Size:

-

Customized Accepted

-

Application:

-

Manufacturing Plant, Machinery Repair Shops,Industry,Vehicle,

-

Color:

-

black,white,grey,ect

-

Free sample:

-

available

-

Process:

-

CNC Machining

-

Technology available:

-

injection mold,extruding mold,cnc machining

-

Certificate:

-

ISO9001

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Konlida

-

Product Name:

-

Wide Varieties Metal Sintering Helical Gear

-

Surface treatment:

-

carbonization, case hardenning

-

Size:

-

Customized Accepted

-

Application:

-

Manufacturing Plant, Machinery Repair Shops,Industry,Vehicle,

-

Color:

-

black,white,grey,ect

-

Free sample:

-

available

-

Process:

-

CNC Machining

-

Technology available:

-

injection mold,extruding mold,cnc machining

-

Certificate:

-

ISO9001

OEM&ODM(Helical gear)

We can make standard gear and special gear as per drawing or sample.

The gear material can be carbon steel,

stainless steel, aluminum, copper, brass

and so on.

Let us know your requirements today!

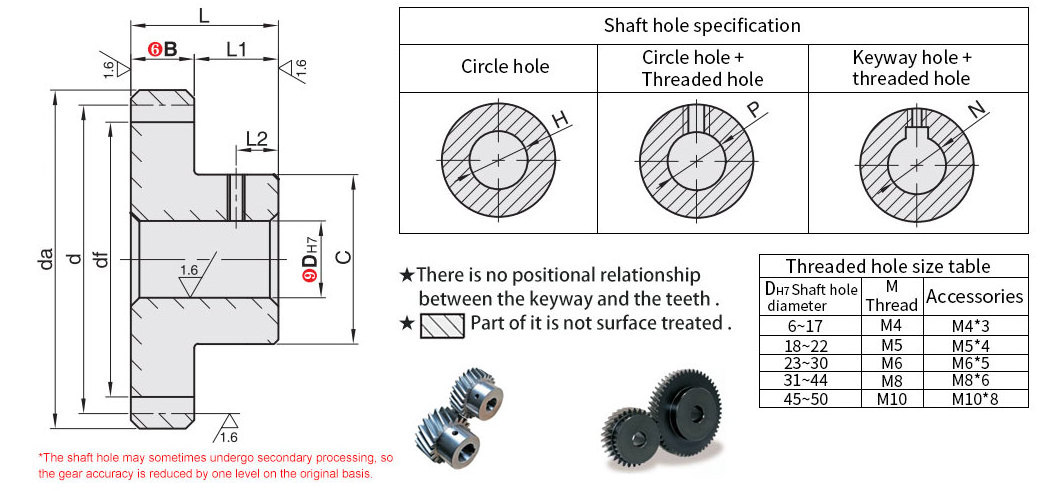

Specification

The helical gear has the advantages of small size, light weight, large transmission torque, stable starting, and finely graded transmission ratio. It can be connected arbitrarily and various installation positions can be selected according to user requirements.

Product Description

Characteristics of The Gear

(1) The meshing of the helical gear is good, the transmission is stable, and the noise is small.

(2) The coincidence of the helical gears is large, which reduces the load of each pair of gears and improves the bearing capacity of the gears.

(3) The minimum number of teeth for helical gears without undercutting is small.

Quenching and Heat Treatment Process

In order to enhance the hardness and wear resistance of the tooth surface, the tooth surface can be subjected to high frequency quenching and heat treatment, thereby increasing the life of the gear

Application

Food Processing/Sewage treatment plant/Filling Machinery/Transport Equipment/Electronic/Medical Instruments/Glass Machinery/Aircraft Accessories/Ship Manufacturin/Appliance/Auto/Industrial equipment metal stamping hardware parts.

Factory

Packing & Delivery

Hot Searches