- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Chipper Blades

-

Package:

-

Wooden Case

-

Material:

-

Cr12MoV , SKD-11 etc

-

Usage:

-

Slitting sheet

-

Precision:

-

High Precession( 0.02mm)

-

Hardness:

-

HRC 44-68

-

Incision:

-

Smooth

-

Advantage:

-

Wear Resistant Superior

-

Size:

-

According to the customer's drawing

-

Sample:

-

Available

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NWP

-

Weight (KG):

-

30 KG

-

Product name:

-

Chipper Blades

-

Package:

-

Wooden Case

-

Material:

-

Cr12MoV , SKD-11 etc

-

Usage:

-

Slitting sheet

-

Precision:

-

High Precession( 0.02mm)

-

Hardness:

-

HRC 44-68

-

Incision:

-

Smooth

-

Advantage:

-

Wear Resistant Superior

-

Size:

-

According to the customer's drawing

-

Sample:

-

Available

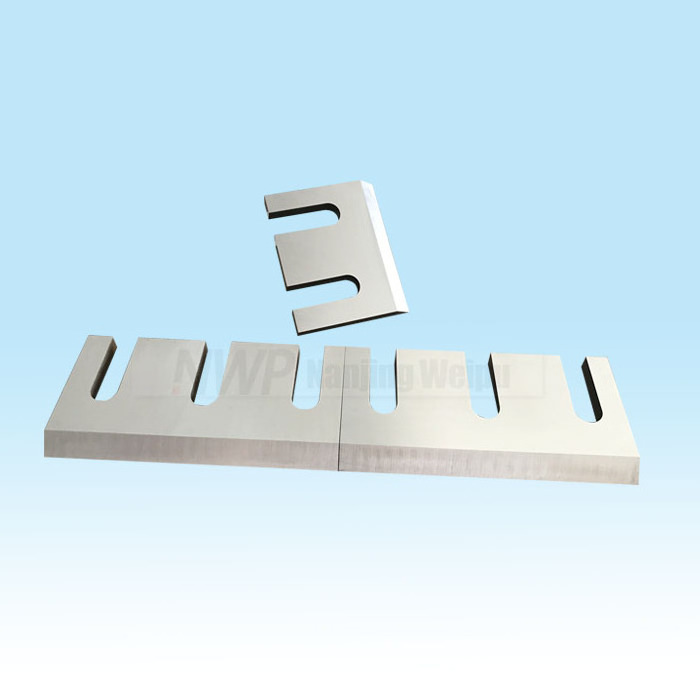

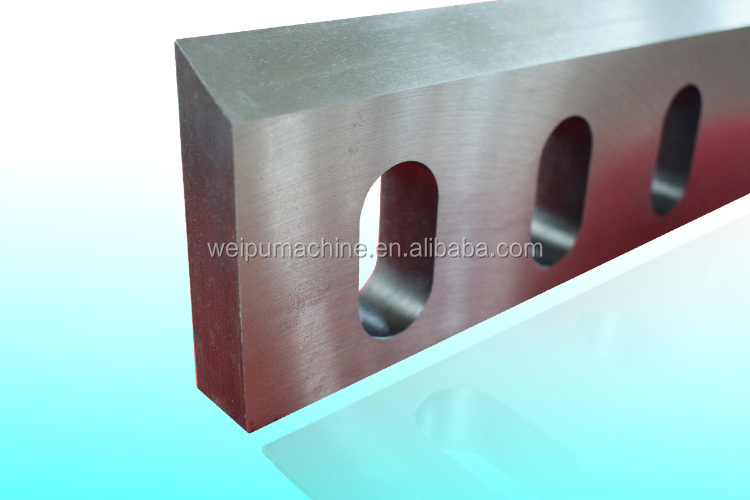

Products Description

|

Product Name

|

Wood Chipper Blades

|

|

Material

|

A8,HSS(W3),D2, H3,SKD11 etc.

|

|

Max length

|

Custom Made

|

|

Hardness

|

44-49 HRC.

|

|

Sample

|

Available

|

|

Sample Delivery Time

|

Within 7-20 working days.

|

|

Application

|

Used for Wood Chipping.

|

|

OEM and ODM

|

Acceptable.

|

|

Delivery Time

|

Within 25 days after receiving down payment.

|

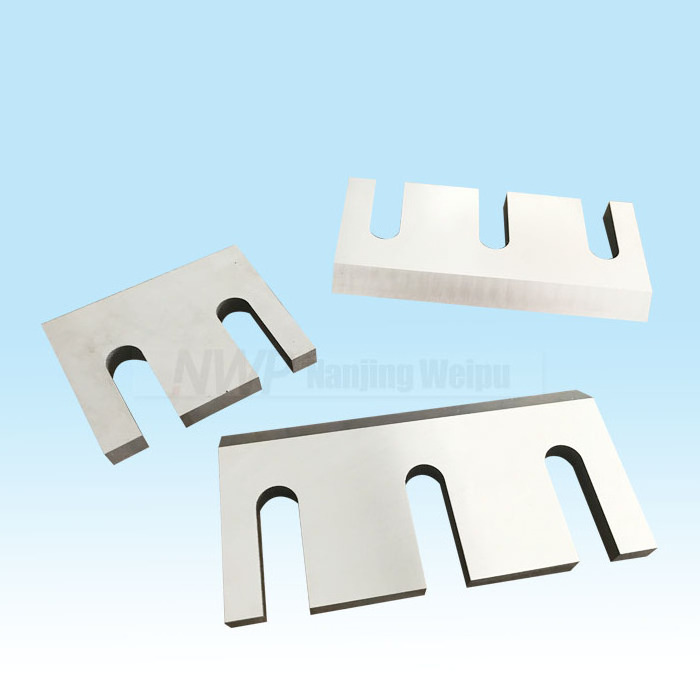

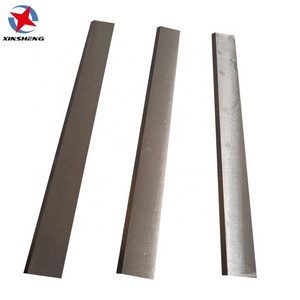

Wood chipper blades are used for slicing, peeling and cutting veneer and plywood.

High-quality tool steel materials and CNC lathe machining and heat treatment ensure the tool's hard wear resistance and dimensional accuracy, thus ensuring excellent cutting performance and high-end quality of the final product.

Product Display

Workshop

Nanjing Weipu Machinery Equipment Co., Ltd.

is an emerging heavy industry enterprise that mainly develops and produces products such as machines, blades and molds, and has multiple production workshops for production. Products are widely used in many industries. Our company produces bending machine molds, shearing machine blades, cutting blades and so on. Mainly used in door and window processing, mechanical processing, Guanghao design, kitchenware production, metallurgical machinery and other industries.

We focus on every process from raw material selection to finished product delivery. We have the most advanced processing equipment and manufacturing technology to ensure that our products have better wear resistance and longer service life, while we also provide the most favorable prices and services.

1. Packed with PE film or kraft paper first to ensure that the product is isolated from air/water/moisture, thus avoiding rust on the product due to long-term transportation;

2. Secondly, use bubble wrap to increase the impact resistance and avoid damage caused by transportation;

3. Rubber anti-skid angle or corrugated angle packaging protects the knife edge from damage;

4. Through the crate of wood screws, it is easy for customers to open the product without damage to the crate after receiving the product;

5. Corrugated box or wooden box, provide good protection and stackability.

Major Market

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in product development.

Q: Can I get the molds sample before ordering?

A: Yes, for standard molds, we will send you a sample for quality inspection. For customized molds, we will start mass production after your approval.

Q: How long is the delivery time?

A: If the product is in stock, usually 3-5 days. For those products that we do not have in stock, this will arrange 20-25 days for production and delivery, but can also be negotiated based on the order quantity and production plan.

Q: How to guarantee the production quality?

A: Our production is based on ISO 9001. We have 15 years of QC team experience and strict quality control system in the production process. Before packaging, we will check each finished product 4 times.

A: We are a professional manufacturer specializing in product development.

Q: Can I get the molds sample before ordering?

A: Yes, for standard molds, we will send you a sample for quality inspection. For customized molds, we will start mass production after your approval.

Q: How long is the delivery time?

A: If the product is in stock, usually 3-5 days. For those products that we do not have in stock, this will arrange 20-25 days for production and delivery, but can also be negotiated based on the order quantity and production plan.

Q: How to guarantee the production quality?

A: Our production is based on ISO 9001. We have 15 years of QC team experience and strict quality control system in the production process. Before packaging, we will check each finished product 4 times.

Q: What are your payment terms?

A: Payment <= 1000USD, 100% in advance. Payment >= 1000USD, 30% T/T in advance, balance before shipment.

A: Payment <= 1000USD, 100% in advance. Payment >= 1000USD, 30% T/T in advance, balance before shipment.

Hot Searches