- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

none

-

Year:

-

new

-

Power (kW):

-

300 kW

-

Weight (KG):

-

10000 KG

-

mainly market:

-

30 more than countries

-

capacity:

-

500-1000kg/h

-

floor area:

-

260 SQ.M

-

equipped with:

-

water cooling system

-

Power:

-

45-110kw

-

Certification:

-

ISO/CE

-

Weight:

-

none

-

Raw material:

-

Waste Tyre

-

Application:

-

Rubbers Recycling Industry

-

After-sales Service Provided:

-

Engineers

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongyu

-

Voltage:

-

220V to 510V

-

Dimension(L*W*H):

-

none

-

Year:

-

new

-

Power (kW):

-

300 kW

-

Weight (KG):

-

10000 KG

-

mainly market:

-

30 more than countries

-

capacity:

-

500-1000kg/h

-

floor area:

-

260 SQ.M

-

equipped with:

-

water cooling system

-

Power:

-

45-110kw

-

Certification:

-

ISO/CE

-

Weight:

-

none

-

Raw material:

-

Waste Tyre

-

Application:

-

Rubbers Recycling Industry

-

After-sales Service Provided:

-

Engineers

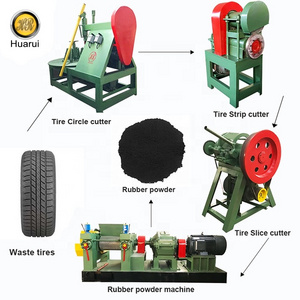

Automatic Waste Tyre Recycling Machine To Rubber Powder / Used Tire Recycling / Waste Tyre Processling Line

Products Description

Application:

Semi-auto waste tyre recycling production line is used to make the waste tyres to rubber power and separate the fiber and steel wire, to achieve the recycling.

|

No.

|

Machine

|

Model

|

Quantity

|

Power

|

||||

|

Whole tire cut processing, get <50*50mm rubber crumb

|

|

|

|

|

||||

|

1

|

Ring cutter

|

ZY-1200

|

1

|

5.5kw

|

||||

|

2

|

Steel wire separator

|

ZY-295

|

1

|

15kw

|

||||

|

3

|

Strip cutter

|

ZY-370

|

1

|

5.5kw

|

||||

|

4

|

Rim cutter

|

ZY-200

|

1

|

11kw

|

||||

|

Rubber power processing, get 20-30 mesh rubber power

|

|

|

|

|

||||

|

5

|

Tire crusher

|

ZY400

|

1

|

45kw

|

||||

|

|

|

ZY450

|

|

55kw

|

||||

|

|

|

ZY560

|

|

75kw

|

||||

|

6

|

Big conveyor belt

|

BCL-8

|

1

|

2kw

|

||||

|

7

|

Small conveyor belt

|

BCL-3

|

1

|

1.1kw

|

||||

|

8

|

Big oscillating screen

|

BSS-8

|

1

|

7.5kw

|

||||

|

9

|

Small oscillating screen

|

BSS-3

|

1

|

3KW

|

||||

|

10

|

Big magnetic plant

|

BMS-22

|

1

|

2.2kw

|

||||

|

11

|

Small magnetic plant

|

SMS-1

|

1

|

1.1kw

|

||||

|

12

|

Fiber Separator

|

FS110

|

1

|

11kw

|

||||

You can according to the below data of the 3 type tyre crusher to chose:

1).ZY400 rubber crusher: Output: 4500-6000kg/24 hour for about 20 mesh granule.

2).ZY450 rubber crusher: Output :7000-12000kg/24 hour for about 20 mesh granule.

3).ZY560 rubber crusher: Output : 10000-17000kg/24 hour for about 20 mesh granule.

Features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),adopt automatic control system for whole line, reduce labor cost;

3),no sewage and waste gas discharge, environment protection.

4), available capacity range of our tyre recycling lines at present: 400~3000kg/h

5), available finial rubber powder size: 20~120mesh.

Details Images

1. ring cutter: To cut the two sides of tyre which has steel wire ring (the steel wire ring is the main supportance for the tyre).

2. steel wire separator: To separator the tyre sides steel wire ring and rubber which is cut from the ring cutter.

3. stripe cutter: Make the whole tyre which is cutted two sides from ring cutter to stripes.

4. rim cutter: To make the stripe to block.

5. tyre crusher: Milling the rubber block to power.

6. conveyor belt, oscillating screen, magnetic roller: To separator the iron power and rubber power and screening the rubber power, make the big rubber power re-milling.

7. fiber separator: separator the fiber from rubber power.

Packing&Shipping

Company Introduction

FAQ

Q: How To Choose A Suitable Tire Recycling Line?

A: Please tell us your capacity and the output size, we will recommend you the most suitable tire recycling line.

Q: Can We Get Very Fine Powder From The Recycling Line?

A: Yes, you can get 20-120mesh fine rubber powder with fine grinder system.

Q: Can You Process OTR Tires?

A: Yes, we have machines special for OTR tires, like OTR tire cutter machine, OTR tire bead cutting machinery, etc.

Q: What About The Machine Installation?

A: We will send engineers to customer working site for the installation guidance, commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

Q: How About The Spare Parts?

A: We provide spare parts at cost price permanently and will give you the spare parts list when you purchase machine.

Q: Will You Test The Machine Before Delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

Hot Searches