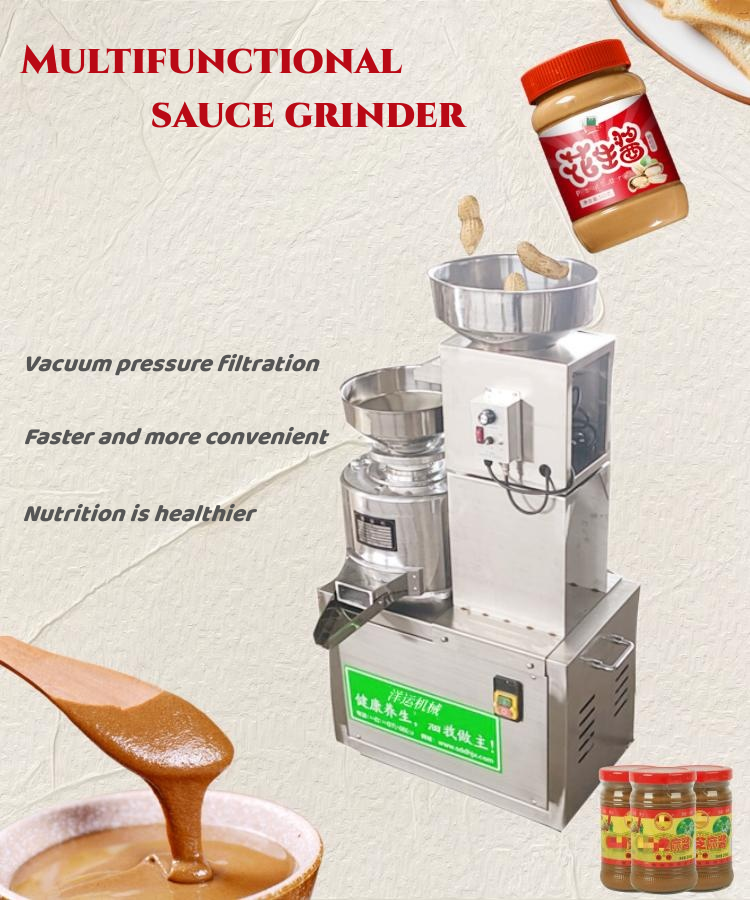

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

3000

-

Dimension(L*W*H):

-

600*400*1000mm

-

Weight:

-

80 KG

-

Output product name:

-

sauce

-

Product name:

-

Sesame Peanut Butter Machine

-

Application:

-

Peanut Butter Line

-

Type:

-

Peanut Butter Maker

-

POWER:

-

1.5kw

-

Material:

-

Stainless Steel

-

Capacity:

-

10-15KG/H

-

Feature:

-

High Efficiency Easy Operation

-

Rotary speed:

-

2800r/h

-

Advantage:

-

Long Working Life

-

Usage:

-

Commercial Usage

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

ocean lucky

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V

-

Power:

-

3000

-

Dimension(L*W*H):

-

600*400*1000mm

-

Weight:

-

80 KG

-

Output product name:

-

sauce

-

Product name:

-

Sesame Peanut Butter Machine

-

Application:

-

Peanut Butter Line

-

Type:

-

Peanut Butter Maker

-

POWER:

-

1.5kw

-

Material:

-

Stainless Steel

-

Capacity:

-

10-15KG/H

-

Feature:

-

High Efficiency Easy Operation

-

Rotary speed:

-

2800r/h

-

Advantage:

-

Long Working Life

-

Usage:

-

Commercial Usage

Product Introduction

The basic principle of a sauce grinder is that fluid or semi fluid materials are subjected to strong shear force, friction force, and high-frequency vibration through high-speed relative movement between fixed and moving teeth, effectively crushing, emulsifying, homogenizing, and warming, thereby obtaining satisfactory and finely processed products.

The structural characteristics of the sauce grinder include two specifications: vertical and horizontal. The main engine is composed of a shell, stator, rotor, regulating mechanism, cooling mechanism, motor, etc. Its main components are made of stainless steel, and the user can choose different specifications and models of colloid mills according to different material characteristics, production efficiency, and purposes, to achieve good results.

Application scope:

1. Food industry: dairy products, chocolate, soy sauce, jam, peanut butter, cream drinks, etc.

2. Chemical industry: pigments, lubricants, spices, dyes, emulsified asphalt, emulsified rubber, catalysts, paint coatings, etc.

3. Pharmaceutical industry: Cod liver oil, confidentiality, health cream, bee queen, pollen, etc.

4. Daily chemical products: shoe polish, toothpaste, cosmetics, balm, soap, detergent, etc.

5. Other industries: construction industry, paper industry, plastic industry, battery industry, etc.

Working principle of sauce grinder

The basic working principle of a sauce grinder is shearing, grinding, and high-speed stirring. Grinding relies on the relative motion of two tooth surfaces, with one rotating at high speed and the other stationary, causing the material passing between the tooth surfaces to experience significant shear and frictional forces. At the same time, under the complex forces of high-frequency vibration, high-speed vortices, etc., the material is effectively dispersed, floated, crushed, and homogenized.

Structure of the sauce grinder

The sauce grinder consists of three parts: a grinding head component, a base transmission component, and an electric motor. All parts in contact with materials are made of high-quality stainless steel. Dynamic and static grinding discs are the key parts of the machine. According to the nature of the materials to be processed, the tooth shape of grinding discs is different, but the materials are made of stainless Tool steel. The motor is specially designed according to the needs of the colloid mill, and a water baffle is installed on the flange end cover of the motor to prevent leakage.

Precautions for operating and using the sauce grinder

Precautions and maintenance for installation and use:

1. The equipment is installed horizontally on a flat concrete foundation and fixed with foundation screws (it may not be fixed according to working conditions).

2. Check if all fastening screws are tightened (the rotor center screw is an M12 left-hand screw).

3. Before use, use a special wrench to rotate the rotor and check for contact with the stator and any jamming. If there are any of the above conditions, it is not allowed to start the machine.

4. Check and connect the power cord (three-phase AC, voltage 380V, body protection grounding) and note that the rotor rotation direction should be consistent with the arrow on the base (clockwise rotation).

5. Connect the cooling water and pay attention to the water inlet and outlet signs of the water nozzle.

6. When starting the motor, first click the switch to check for any noise or vibration. If the situation is not normal, immediately shut down the machine, eliminate the fault, and then try running again.

7. When cleaning residual materials in the stator and rotor after work, it should be carried out in the running state. First, rotate the large chuck counterclockwise by no less than 90 ° before cleaning.

8. Method for adjusting the clearance between the stator and rotor (adjustment should be carried out under operating conditions):

a. Loosen two handles b, move the handle to drive the large chuck to rotate, adjust the gap, and rotate the positioning disc clockwise to reduce the gap, resulting in a finer particle size of the material. The clearance increases when rotating counterclockwise, resulting in coarse particle size of the material.

c. After adjusting the clearance between the stator and rotor, both handles should be tightened simultaneously (clockwise).

d. According to the particle size and batch requirements of the processed materials, after selecting the clearance between the stator and rotor, the limit screw can be adjusted to achieve the limit purpose.

9. The butter cup should be filled with oil regularly.

10. Requirements for processing materials:

a. Cannot process dry solid materials, only wet processing can be performed.

b. Before grinding, debris should be removed. The particle size of the material should be less than 1mm, and the hardness of the material should not exceed HV309. It is strictly prohibited for hard objects such as iron and crushed stone particles to enter the grinding head to prevent damage to the machine.

11. According to the material processing requirements, one or more grinding can be carried out, and several experiments should be conducted before grinding to ensure clearance and flow rate.

12. Always pay attention to the working condition and running time of the grinding before use. If there is any abnormal situation, the machine should be immediately shut down and disassembled for inspection.

13. Disassembly of stator assembly (please note that stator assemblies 1, 2, and 3 must not be disassembled). Firstly, remove the hopper and remove the inlet and outlet nozzles, loosen the cap screws, remove the dial, hold the handle, rotate counterclockwise to remove the large chuck, and lift the grinding head cover upwards to remove the stator assembly.

14. Disassembly of the rotor assembly (please note that the first and second stage rotors of the rotor assembly must not be disassembled). After lifting out the stator, remove the discharge port and unscrew the left-hand screw to remove the rotor and impeller. The assembly of the rotor and stator can be carried out in the opposite order above, and each component should be cleaned before assembly. During installation, it is necessary to apply lubricating oil that meets the requirements on all contact surfaces and threaded parts before assembly.

15. After using the sauce grinder or not in use for a short period of time, the inner cavity should be cleaned well to prevent corrosion, and it is best to dry it with high-pressure air. When cleaning, choose appropriate cleaning agents based on different materials, but ensure that the sealing components are not damaged (using nitrile rubber as the sealing material).

16. During disassembly and assembly, attention should be paid to ensuring that all sealing rings are not damaged, misplaced, or lost.

17. When replacing the belt pulley according to the required number of revolutions, first loosen the nut on the motor cover end, push the motor horizontally towards the grinding head direction to loosen the triangular belt, lay down the machine, and then unscrew the nut on the main shaft and the sturdy screw on the motor shaft to remove the original belt pulley. When replacing the required pulley, you can gently tap it in with a hammer and do not use heavy force to avoid damaging the pulley and damaging the accuracy of the machine. After replacement, tighten with nuts and screws, and then gently stand the machine up. After the machine is erected, push the motor horizontally to tighten the V-belt, and then install the cover plate.

Maintenance of the sauce grinder

1. The sauce grinding machine is a high-precision machine with a fast operating speed of up to 20 meters per second, and the clearance between the grinding discs is extremely small. After maintenance, a dial gauge must be used to correct the coaxiality between the surface inside the shell and the spindle to ensure an error of ≤ 0.05mm.

2. When repairing the machine, it is not allowed to directly strike it with an iron hammer during the disassembly, reassembly, and adjustment process. Instead, a wooden hammer should be used. Alternatively, place a wooden standing colloidal grinding block and gently tap it to avoid damaging the other part. Both dynamic and static grinding discs have special tools for disassembly.

3. The seal of this machine is divided into static seal and dynamic seal. The dynamic seal uses mechanical seal and combined seal, the static seal uses O-ring, the fastener uses red copper gasket seal, and the screw seal uses polytetrafluoroethylene Thread seal tape. The mechanical seal is made of chromium corundum ceramic and should be replaced if it is found to be broken. Scratches should be ground, which can be done on flat plates or flat glass. Grind with ≥ 200 # carbonized silicon grinding paste.

4. The use of this machine should be regularly maintained according to the condition of the processed materials. If there are no changes to the processed materials during normal operation, the use can be postponed.

| Model | YY-YM102 |

| weight | 80kg |

| yield | 50kg /h |

| Motor power | 3kw |

| dimension | 600*400*1000mm |

| use | Can grind a variety of nut butter: peanut butter, tahini, almond jam, pistachio jam, cashew jam, cocoa jam, Bigan jam, walnut jam, hazelnut jam, etc |