Coil inner Diameter: ¢460-520mm

Max out diameter of the coil: ¢1500mm

Max Coil Width: 500mm

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sussman

-

Voltage:

-

220V

-

Power:

-

5.5-7.5 kw

-

Dimension(L*W*H):

-

1300*650 *1500 mm

-

Weight:

-

5000 kg, 7.5T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control System:

-

PLC Control

-

Profile Thickness:

-

0.4-1mm

-

Forming speed:

-

10-15m/min

-

Main motor power:

-

7.5kw

-

Cutting mode:

-

pneumatic flying saw tracking cutting

-

Rolling material:

-

45# steel

-

Diameter of the roller:

-

80mm

Quick Details

-

Pipe Material:

-

Galvanized Steel

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

220V

-

Power:

-

5.5-7.5 kw

-

Dimension(L*W*H):

-

1300*650 *1500 mm

-

Weight:

-

5000 kg, 7.5T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control System:

-

PLC Control

-

Profile Thickness:

-

0.4-1mm

-

Forming speed:

-

10-15m/min

-

Main motor power:

-

7.5kw

-

Cutting mode:

-

pneumatic flying saw tracking cutting

-

Rolling material:

-

45# steel

-

Diameter of the roller:

-

80mm

Product Description

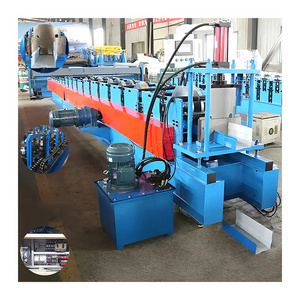

Down Pipe forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling, continuous rolling and cold-forming, automatically cut to the size and specification which is required, and output the finished panels. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

Technical Parameter:

1. Machine specification: Material: can be steel, colored steel or aluminum,

Material thickness: 0.3-0.6mm, yield strength 250 Mpa to 550 Mpa, coil width is according to the final profile, length is up to 12m

2. Forming speed: 0-5m/min

3. Forming roller: about 20 stations

4. Main motor power: 7.5KW

5. Hydraulic station power:5.5KW

6. Roller material: 45# forged steel, surface coated with chrome

7. Main shaft material: 45# steel

8. Main axis dia.: ¢68mm

9. Hydraulic cutting pressure: 10-12Mpa

10. Cutting method: hydraulic powered, cutting after roll forming.

11. Cutting blade material: Cr12Mov quenching treatment

12. Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

Material thickness: 0.3-0.6mm, yield strength 250 Mpa to 550 Mpa, coil width is according to the final profile, length is up to 12m

2. Forming speed: 0-5m/min

3. Forming roller: about 20 stations

4. Main motor power: 7.5KW

5. Hydraulic station power:5.5KW

6. Roller material: 45# forged steel, surface coated with chrome

7. Main shaft material: 45# steel

8. Main axis dia.: ¢68mm

9. Hydraulic cutting pressure: 10-12Mpa

10. Cutting method: hydraulic powered, cutting after roll forming.

11. Cutting blade material: Cr12Mov quenching treatment

12. Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

Machine List:

|

Serial No.

|

Commodity & Description

|

Quantity

|

|

1

|

3T manual uncoiler

|

1 set

|

|

2

|

Feeding with guide

|

1 set

|

|

3

|

Main roll forming machine

|

1 set

|

|

4

|

Straighten device

|

1 set

|

|

5

|

Hydraulic cutting equipment

|

1 set

|

|

6

|

Output table

|

1 set

|

|

7

|

Main drive

|

1 set

|

|

8

|

Hydraulic system

|

1 set

|

|

9

|

Controlling system (including cabinet)

|

1 set

|

|

10

|

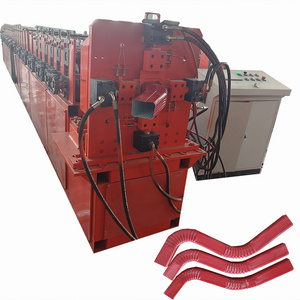

Downpipe elbow bending machine

|

1 set

|

|

11

|

Seaming machine

|

1 set

|

|

12

|

Safety cover

|

1 set

|

|

13

|

Spare parts

|

1 package

|

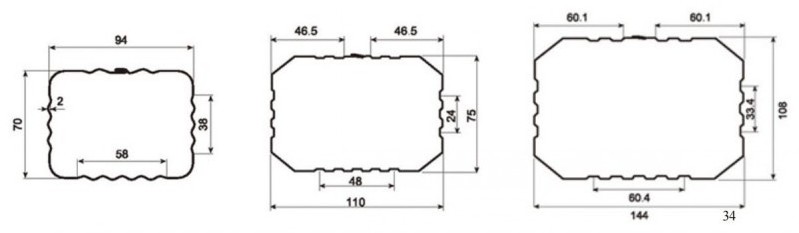

Profile Drawings:

Product Display

3 Tons Passive Decoiler

Feeding with guide

Put the raw material (steel plate) through the beach to manufacture and

process, it can guarantee that the products are neat, parallel and

everything is uniformity.

process, it can guarantee that the products are neat, parallel and

everything is uniformity.

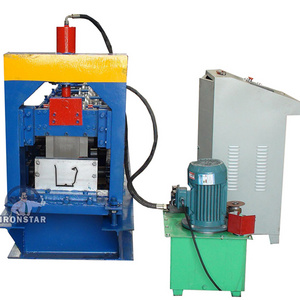

Hydraulic Cutting

(1) Cutting after forming: Cut the sheet after roll forming to required length

(2) Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will

automatically start.

(3) Material of blade: CR12Mov with heat treatment

(4) Length measuring: Automatic length measuring

(5) Hydraulic station power:4KW

(6) Valve:Beijing huade

(2) Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will

automatically start.

(3) Material of blade: CR12Mov with heat treatment

(4) Length measuring: Automatic length measuring

(5) Hydraulic station power:4KW

(6) Valve:Beijing huade

Output Table

It adopts welded steel and supported roller to transmit the products.

Size:4000*1350*1000mm

Size:4000*1350*1000mm

Application

Hot Searches