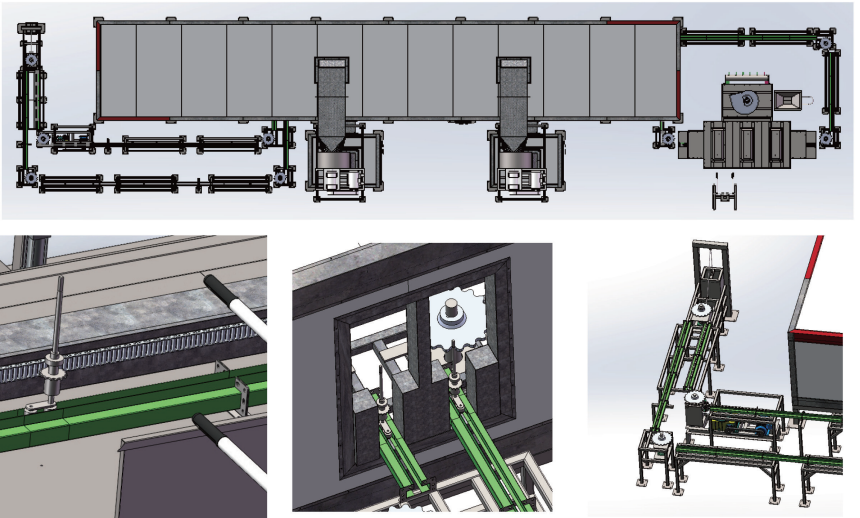

Multi controllers of COLO-800D automatic powder coating machine installed on a central cabinet, with compact design and simple

operation. spraying guns are mounted on an arm extended from a carriage, whose movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

based on clients' standard

-

Power:

-

50W

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Item:

-

Automatic Powder Coating Line

-

Power range:

-

110v-380V

-

Frequency:

-

50HZ /60HZ

-

Temperature range in use:

-

-10 ℃+50 ℃

-

Rated output voltage:

-

24VDC

-

Usage:

-

Metal powder coating

-

Maximum output voltage:

-

0-100KV ( adjustable)

-

Maximum powder injection:

-

600g/min

-

Installation way:

-

Install drawing or engineer provided

Quick Details

-

Machine Type:

-

automatic powder coating line, Spray Booths, Plc Controller Programmable Logic Controller, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KAFAN

-

Voltage:

-

based on clients' standard

-

Power:

-

50W

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

1000

-

Item:

-

Automatic Powder Coating Line

-

Power range:

-

110v-380V

-

Frequency:

-

50HZ /60HZ

-

Temperature range in use:

-

-10 ℃+50 ℃

-

Rated output voltage:

-

24VDC

-

Usage:

-

Metal powder coating

-

Maximum output voltage:

-

0-100KV ( adjustable)

-

Maximum powder injection:

-

600g/min

-

Installation way:

-

Install drawing or engineer provided

Product Description

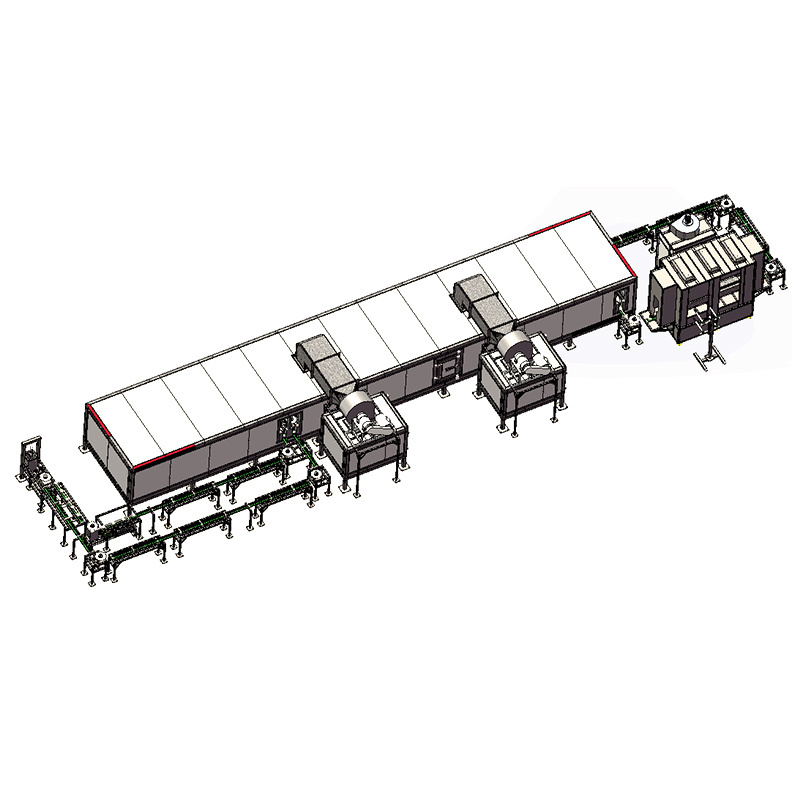

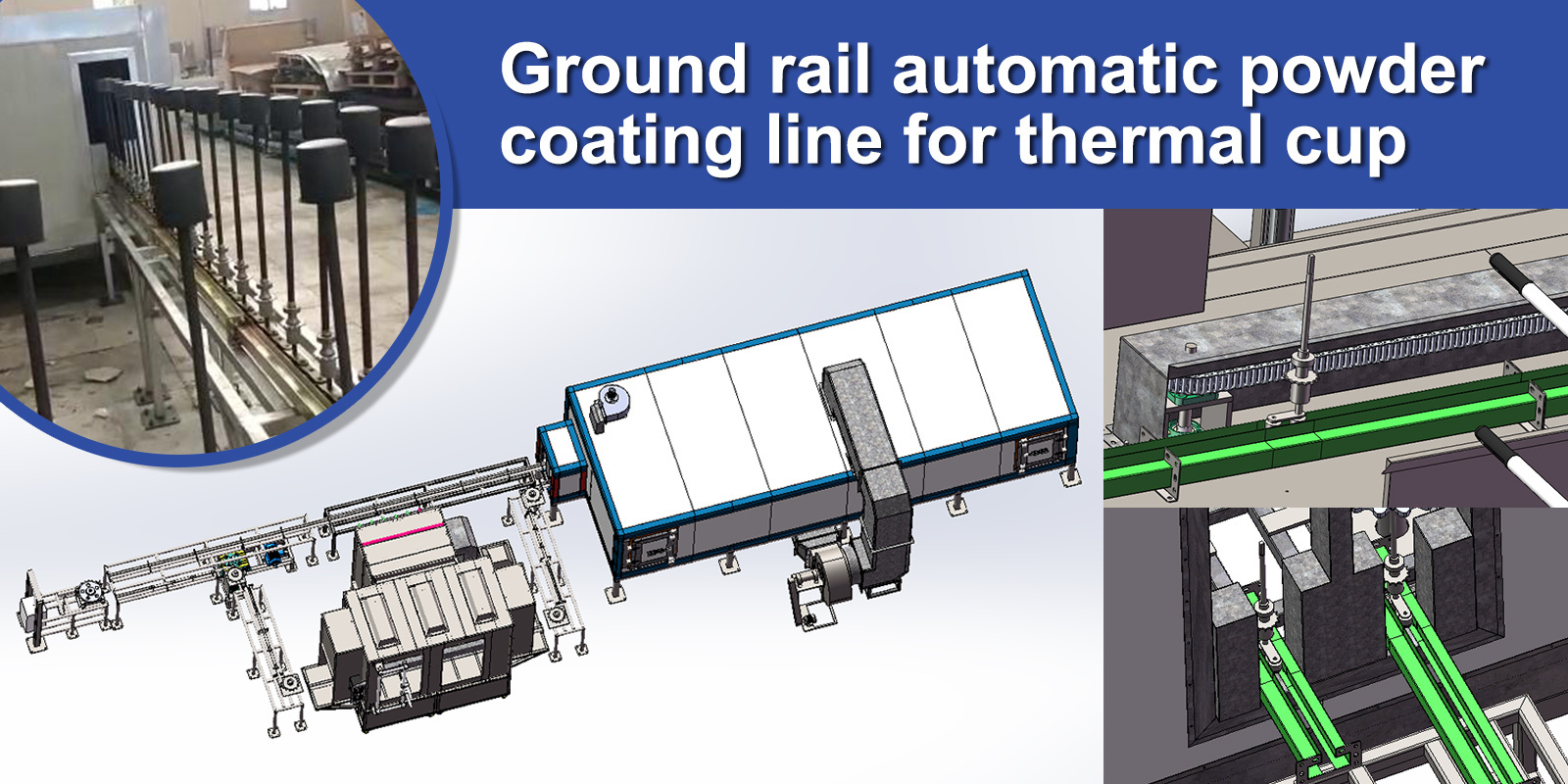

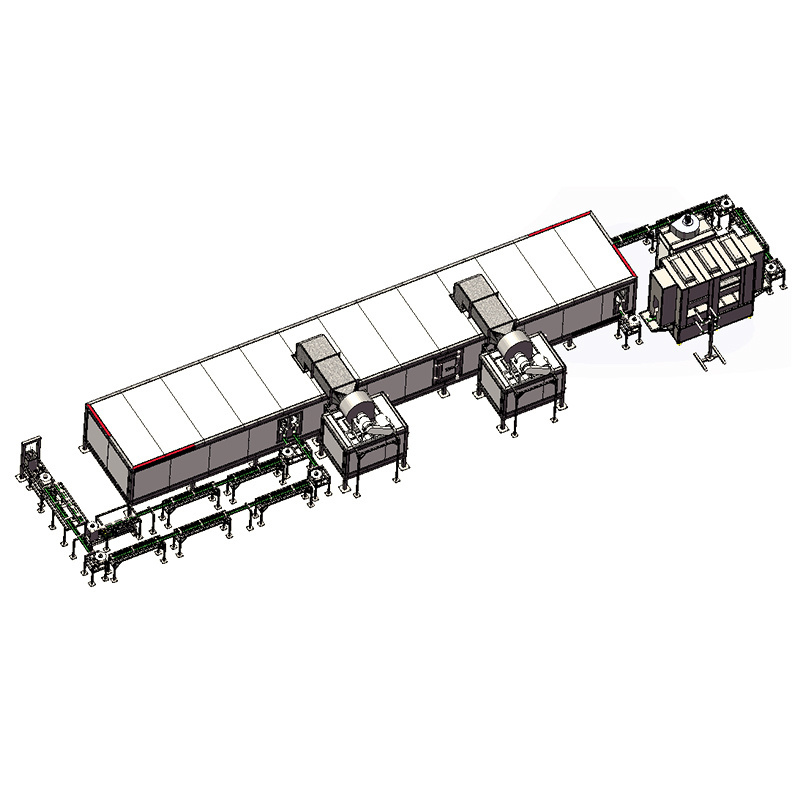

Customized Automatic Powder Coating Plant Line for Metal Cup

This g

round rail

automatic powder coating line is specially designed for Algeria customer's thermal cup. It widely used for continuous finishing of metal cups and workpieces that are difficult to hang.

We provide professional service of powder coating line designing, manufacturing, assembling, commissioning and training for oversea countries.

Suitable for factory size more than : L24000 * W6500 * H4850mm

Features of Automatic Powder Coating Line

1) Conveying system: ground rail conveying system, using a chain rotary conveying will more convenient and stable.

4) Powder supply center: maximize the performance of powder feeding, cleaning and control.

1) Conveying system: ground rail conveying system, using a chain rotary conveying will more convenient and stable.

2) Powder coating booth:

customized tunnel powder spray booth

has improved

the efficiency of the coating system

.

3) Automatic powder coating gun: for consistent and uniform powder coating.

4) Powder supply center: maximize the performance of powder feeding, cleaning and control.

5)

Customized curing oven:

uniform heating temperature ensure quality cured results.

Details Images

COLO-800D

Automatic powder coating guns

This automatic powder sieving machine is connected in the automatic powder coating line, full automatic operations increases

working efficiency. Mainly working purpose of the automatic powder sieving machine is: recycling the old powder back to spray gun

and avoiding powder accumulation. It also can do the check or safety sieving and efficiency separate foreign materials and

oversized particles in raw powder.

working efficiency. Mainly working purpose of the automatic powder sieving machine is: recycling the old powder back to spray gun

and avoiding powder accumulation. It also can do the check or safety sieving and efficiency separate foreign materials and

oversized particles in raw powder.

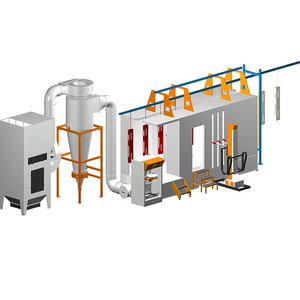

Customized Automatic Powder Coating Booth

It is an automatic type tunnel powder coating booth with filter powder coating room to realize a certain larger powder coating job.

The inner size of the spray booth is: W1120*H1500*L2900MM

Opening size: W600*H600MM

Manual size W600*H1100MM

1 . Equipped with 4 pcs automatic spray guns fixed with bracketsand one manual spray gun

2 . Equipped with one set of filters room , Fours groups of filter element

3 . Select one set 3kw centrifugal fan , air volume : 4500m3/hh

COLO Customized Powder Coating Oven

This customized powder coating oven according to customer workpieces to meet different sizes and curing needs, uniform heating temperature ensure quality cured results.

1 . Size of the curing oven : W *H * L : 2300 *1100 * 14600mm

2 . Voltage / Frequency : 380V / 220V( 50-60hz)

3 . Motor power : 5.5kw, 2pcs

4 . Heating Power : Electric heating , 252KW , 84 pcs heating tubes of 3kw

It is conveyed through the ground track conveying system, using a chain rotary conveying will more convenient and stable. It especially suitable for batch production, improving production efficiency.

The conveying speed is 2.5 meters per minute. The frequency conversion is adjustable, and the interval betweeneach workpiece is 200mm

|

Powder Coating Line Specifications

|

Specifications

|

|

|

Powder Spray Booth

|

|

|

|

Powder Spray Booth Size:

|

With1120 * Height1500 * Depth2900mm

|

|

|

Powder Recovery

|

Cartridge Filters, 4pcs

|

|

|

Fan Motor

|

1 set, 3kw 4500m3/h

|

|

|

Spray Booth Material:

|

SPCC/=1.5mm

|

|

|

Powder Coating Equipment

|

|

|

|

Automatic Powder Guns

|

COLO-800D Automatic Type, 4pcs.

|

|

|

Output High Voltage

|

Max. 100kv

|

|

|

Central Contral Cabinet

|

1 set

|

|

|

Drying/Curing Oven

|

|

|

|

Drying/Curing Oven Size:

|

With2300 * Height1100 * Depth14600mm

|

|

|

Heating Source

|

Electric

|

|

|

Heating Power

|

252KW, 84 pcs heating tubes of 3kw

|

|

|

Heating Time & Temperature

|

Warm-up time: 15-30 min. (180° C), Max.250° C

|

|

|

Circulation Fan

|

5.5kw, 2sets

|

|

|

Ground Rail

|

|

|

|

Ground Rail Length

|

125m

|

|

|

Round Rail Conveying Speed

|

25m/min

|

|

Customer Feedback

Hot Searches