The reducer is generally used for low-speed and high-torque transmission equipment. The motor, internal combustion engine or other high-speed running power is used to achieve the purpose of deceleration by meshing with the large gear on the output shaft through a gear with a small number of teeth on the input shaft of the reducer. The reducer will also have several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

42 - 750rpm

-

Weight (KG):

-

1

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HPS

-

Gears Style:

-

Planetary Gear Arrangement

-

Material of gear:

-

High Precision Grinding

-

Mounting Position:

-

Motor

-

Material of Shaft:

-

40Cr

-

Heat treatment:

-

Gear Grinding

-

Size:

-

60*60mm

-

Gear Ratio:

-

4/5/7/10/16/20/25/40/50/70:1

-

Gear type:

-

Straight

-

Keywords:

-

Low backlash

-

Matching motor:

-

Servo Motor

Quick Details

-

Gearing Arrangement:

-

Planetary

-

Output Torque:

-

5-45N.m

-

Input Speed:

-

3000 rpm

-

Output Speed:

-

42 - 750rpm

-

Weight (KG):

-

1

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

HPS

-

Gears Style:

-

Planetary Gear Arrangement

-

Material of gear:

-

High Precision Grinding

-

Mounting Position:

-

Motor

-

Material of Shaft:

-

40Cr

-

Heat treatment:

-

Gear Grinding

-

Size:

-

60*60mm

-

Gear Ratio:

-

4/5/7/10/16/20/25/40/50/70:1

-

Gear type:

-

Straight

-

Keywords:

-

Low backlash

-

Matching motor:

-

Servo Motor

Product Description

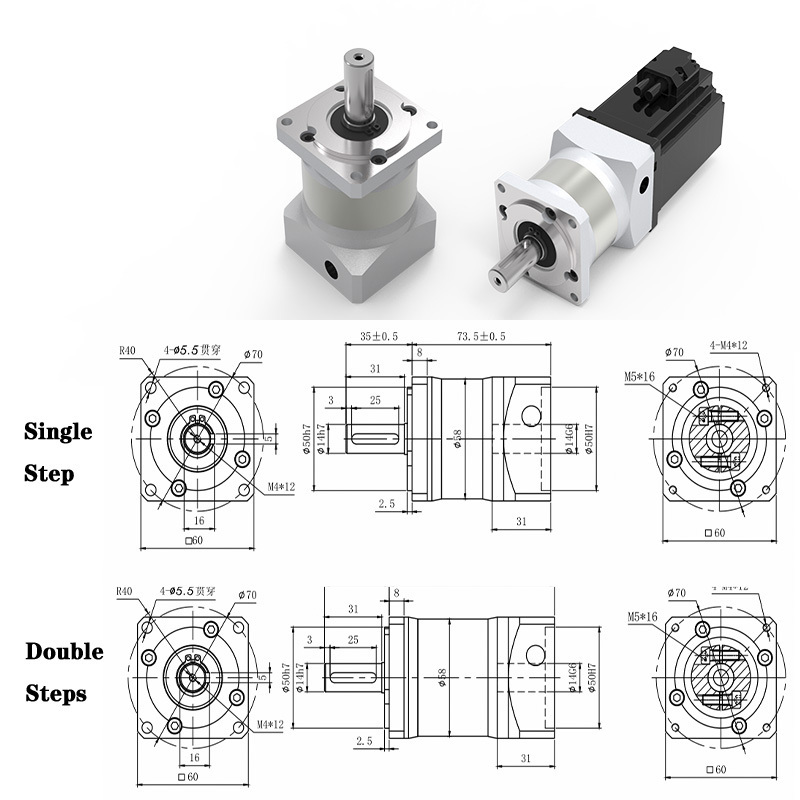

Products Parameters

|

SPECIFICATIONS

|

STAGE

|

RATIO

|

RATED TORQUE(N.m)

|

||

|

|

L1

|

4

|

25

|

||

|

|

|

5

|

28

|

||

|

|

|

7

|

20

|

||

|

|

|

10

|

10

|

||

|

|

L2

|

16

|

30

|

||

|

|

|

20

|

30

|

||

|

|

|

25

|

32

|

||

|

|

|

28

|

30

|

||

|

|

|

35

|

30

|

||

|

|

|

40

|

25

|

||

|

|

|

50

|

25

|

||

|

|

|

70

|

20

|

||

|

Adapted motor

|

60 Servo Motor

|

|

|

||

|

Rated Input Speed (rpm)

|

3000 RPM/min

|

|

|

||

|

Max Input Speed (rpm)

|

6000 RPM/min

|

|

|

||

|

Backlash

|

L1

|

≤10 Arcmin

|

|

||

|

|

L2

|

≤15 Arcmin

|

|

||

|

Fault stop torque(N.m)

|

2 times of rated torque

|

|

|

||

|

Efficiency

|

L1

|

96%

|

|

||

|

|

L2

|

94%

|

|

||

|

Average life span

|

20000/h

|

|

|

||

|

Operating temperature

|

-10°~+90°

|

|

|

||

|

Nosie

|

≤60 db

|

|

|

||

|

Weight (kg)

|

L1

|

0.75

|

|

||

|

|

L2

|

1

|

|

||

|

IP

|

54

|

|

|

||

|

Installation method

|

Any installation method

|

|

|

||

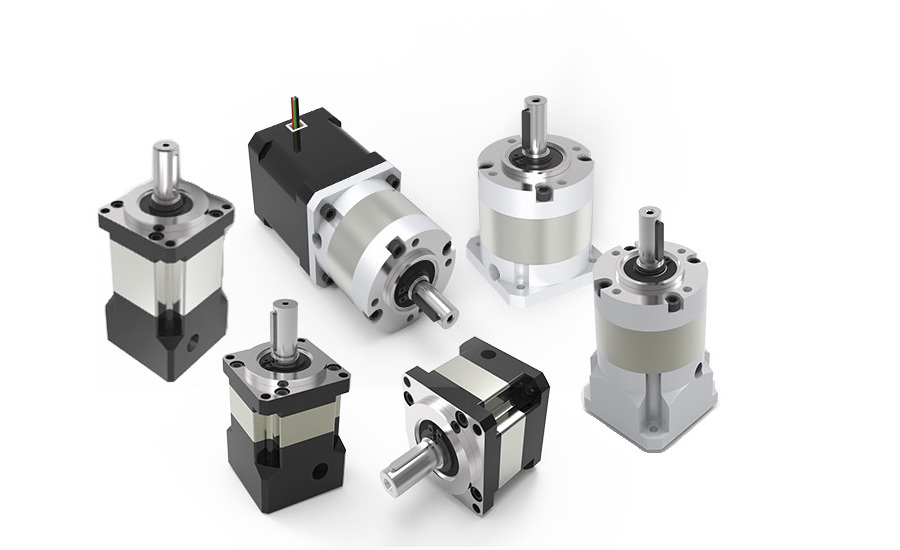

Production Range

42 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 12,16,20,25,28,35,40,50,70

Frame Dimension: 42mm Input Flange

Gear Arrangement: Planetary Straight Teeth

Ratio Selection:

L1: 4,5,7,10,

L2: 12,16,20,25,28,35,40,50,70

Frame Dimension: 42mm Input Flange

Gear Arrangement: Planetary Straight Teeth

60 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm Input Flange

Gear Arrangement: Planetary Straight Teeth

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm Input Flange

Gear Arrangement: Planetary Straight Teeth

90 Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 90mm Input Flange

Gear Arrangement: Planetary Straight Teeth

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 90mm Input Flange

Gear Arrangement: Planetary Straight Teeth

Right Angle Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10, L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm & 90mm

Gear Arrangement: Planetary Straight Teeth

Ratio Selection:

L1: 4,5,7,10, L2: 16,20,25,28,35,40,50,70

Frame Dimension: 60mm & 90mm

Gear Arrangement: Planetary Straight Teeth

Powder Metal Series Planetary Gearbox

Backlash: 10-15 arcmin

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 42mm & 57mm

Gear Arrangement: Planetary Straight Teeth

Ratio Selection:

L1: 4,5,7,10,

L2: 16,20,25,28,35,40,50,70

Frame Dimension: 42mm & 57mm

Gear Arrangement: Planetary Straight Teeth

Solar Gear Motor

Output Torque: 60 - 660 N.mIP: 65

Customized Service: OEM, ODM.

Application: Solar Tracker System / Solar Panels Cleaning Robot / Other Industry Machine

Customized Service: OEM, ODM.

Application: Solar Tracker System / Solar Panels Cleaning Robot / Other Industry Machine

NEMA Series Stepper Motor

Motor Type: NEMA 8 -- NEMA 42Step Accuracy: 5%

Adapted Gearbox Diameter(mm): 20, 28,35,39,42,57,60,86,110

Ambient Temperature Range:

-20°C ~ +50°C

Adapted Gearbox Diameter(mm): 20, 28,35,39,42,57,60,86,110

Ambient Temperature Range:

-20°C ~ +50°C

Application Field

Automatic Arms

Assembly Line

3D-Printer

Medical -Equipment

CNC Machine

Tapping Machine

Other Automation Devices

Assembly Line

3D-Printer

Medical -Equipment

CNC Machine

Tapping Machine

Other Automation Devices

Why Choose Us

Anhui High Precision Gear

Transmission Co., Ltd

COMPANY PROFILE

Anhui High Precision Gear Transmission Co., Ltd located in Chuzhou city, Anhui Province, China. It is a leading company dedicated in precision transmission parts and system research, manufacture and sales, various series of products are manufactured in its 5000 square meters workshop, the precision planetary gearbox and gear motor are developed especially for solar energy industry and have served many large-scale solar projects worldwidely.

The research team has more than 15 years experiences in this field, who can ensure a punctual and efficient service to meet customer's specific needs. It has pasted the ISO9001 quality management system and CE, products have been exported to lots of countries with a wide range application in AGV, intelligent robot, logistic, industrial automation, solar energy, vessel, packaging and textile etc.Consistently, our goal is to promote the application of solar power industry in the world, and we believe it provides clean and sustainable energy for humanity to better protect our environment.

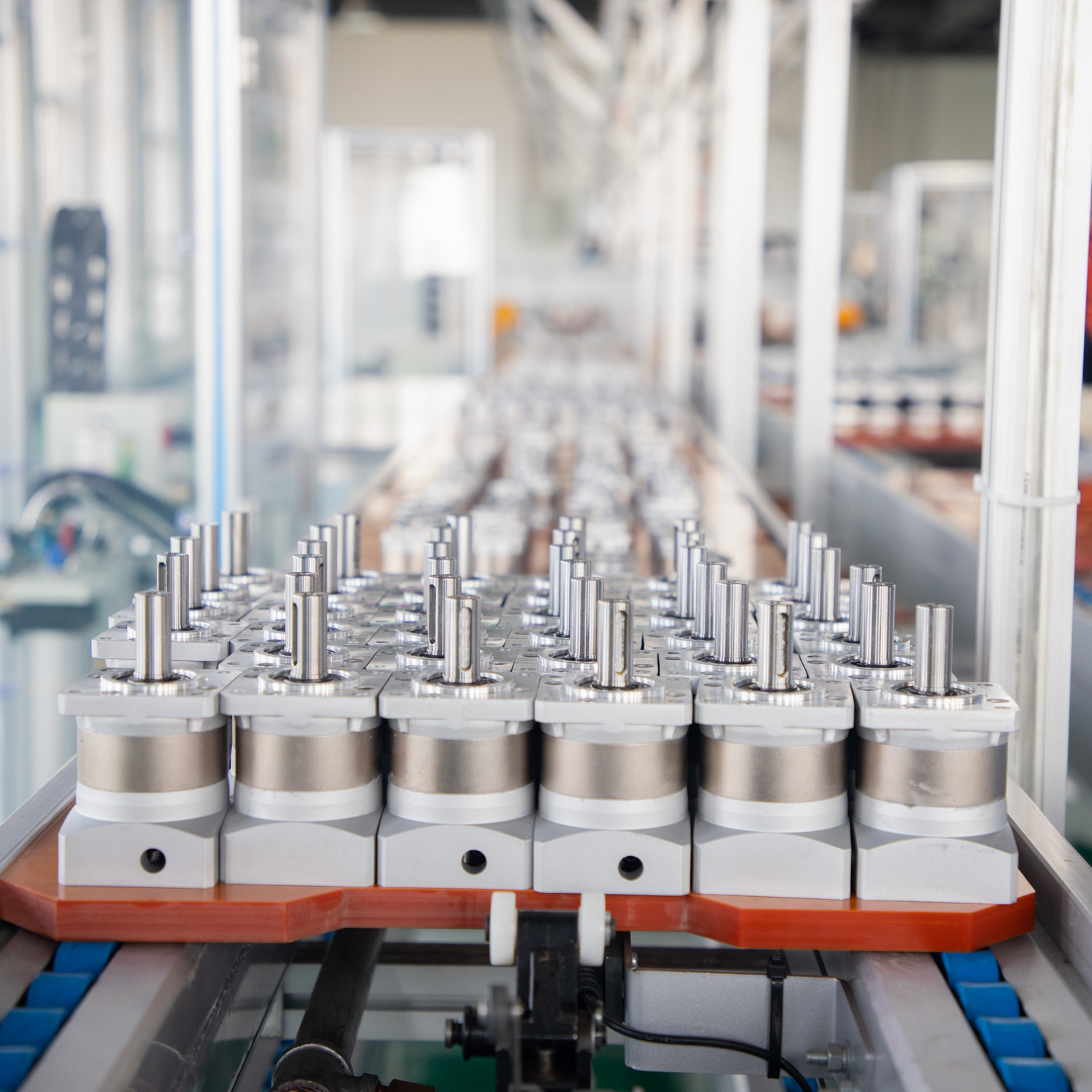

WORKSHOP

TEAM

CERTIFICATIONS

LOGISTICS

FAQ

Q:Which areas are your products mainly used in?

A:At present, we have two main products: precision planetary gear reducer and solar geared motor. Most of the precision planetary reducers are used in automation fields, such as medical equipment, 3D printers, door openers, tapping machines, CNC lathes and a series of automation equipment. In addition, our solar geared motors are used in photovoltaic power generation projects, which are mainly combined with rotary drives to drive solar panels to track sunlight.

Q : How to choose the suitable planetary gearbox?

A :First of all, we need you to be able to provide relevant parameters. If you have a motor drawing, it will let us recommend a suitable gearbox for you faster. If not, we hope you can provide the following motor parameters: output speed, output torque, voltage, current, IP, noise, operating conditions, motor size and power, etc.

Q : What is the price ?

A : The main determining factor for the price of each product is the order volume. You can communicate with us and let us understand each other. I believe that our prices, product quality and our services can definitely make you satisfied.

Q : Do you provide customized service?

A: Yes, we provide customized services. You only need to put forward your needs, and we will do our best to provide you with a plan, make plans, and try our best to meet your needs.

Hot Searches