Click Here To Get Quotation

Daelim Transformers are developed and produced especially to satisfy exacting customer's exact specification. Daelim Transformer continuously commited to providing high-qualty products: high voltage,no drifting of neutral point,low loss, small volume,cost-effctive,safety and environment protection,with atrative appearance,elc.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

single phase pad mounted transformer

-

Coil Number:

-

3

-

Use:

-

distribution

-

Product name:

-

Pole Mounted Transformer

-

Type:

-

Pad Mounted

-

Application:

-

Industrial Power Supplies

-

Standard:

-

IEC ANSI IEEE

-

Winding material:

-

Copper\Aluminum

-

Primary voltage:

-

12.4/13.2/13.8/34.5kv

-

Vector Group:

-

Dyn1 / YNyn0

-

Frequency:

-

60 Hz

-

Cooling Method:

-

ONAN ONAF

-

Core material:

-

Silicon Steel

-

Rated Primary Voltage:

-

13800

-

Rated Secondary Voltage:

-

120

-

Power:

-

50KVA

Quick Details

-

Phase:

-

Single

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DAELIM BELEFIC

-

Model Number:

-

single phase pad mounted transformer

-

Coil Number:

-

3

-

Use:

-

distribution

-

Product name:

-

Pole Mounted Transformer

-

Type:

-

Pad Mounted

-

Application:

-

Industrial Power Supplies

-

Standard:

-

IEC ANSI IEEE

-

Winding material:

-

Copper\Aluminum

-

Primary voltage:

-

12.4/13.2/13.8/34.5kv

-

Vector Group:

-

Dyn1 / YNyn0

-

Frequency:

-

60 Hz

-

Cooling Method:

-

ONAN ONAF

-

Core material:

-

Silicon Steel

-

Rated Primary Voltage:

-

13800

-

Rated Secondary Voltage:

-

120

-

Power:

-

50KVA

Single phase 15kva 25kva 37.5kva 50kva 75kva 100kva 167kva pad mounted transformer

Products Description

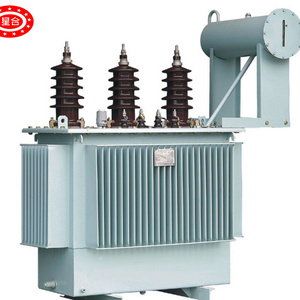

Single phase pad mounted transformer

Daelim Transformer produces muliple standards of single phase pad-mounted transfomers. They are available in standard ratings and configurations or can be customized to meet specific needs.

Single phase pad mounted transformers are placed inside a cabinet with doors and locks, usuallylocated outdoors. These transformers are manulactured with ratings from 15-250 kVA.

Al of these distribution transformers are oil-insulated, sef-cooled,available in loop or radial feed, and are dead-front

These transformers come in two basic configurations radia and loop feed,which are selectied based on the type of circuit on which the transformers wil be insalled. The transformer uses aluminum or copper winding and is optimized to maximize efficency and fooprint The latest applicable standards(ANSI,IEEE, DOE, CSA and NEMA) have been applied to all of Daelim Transformers.

Local after-sales service

Complete after-sales service and installation teams in Canada, USA, Ecuador, etc.Provide 24 hours of technology and consulting services. There are local cooperation after -sales service teams with rich experience in power engineering and timely services.

Tansformer solutions

Daelim Transformer not only produces transformers, but also provides the best solution for your power project. Such as mines, factories, renewable energy power generation (wind power, solar power and BESS, etc.) to provide the best transformer solutions.

Transformer customization service

Daelim has more than 20 years of experience in exporting transformers, and the team of engineers is particularly professional and proficient in various international standards. No matter which country you are from, the team of engineers can design and produce

according to your requirements and technical parameters.

according to your requirements and technical parameters.

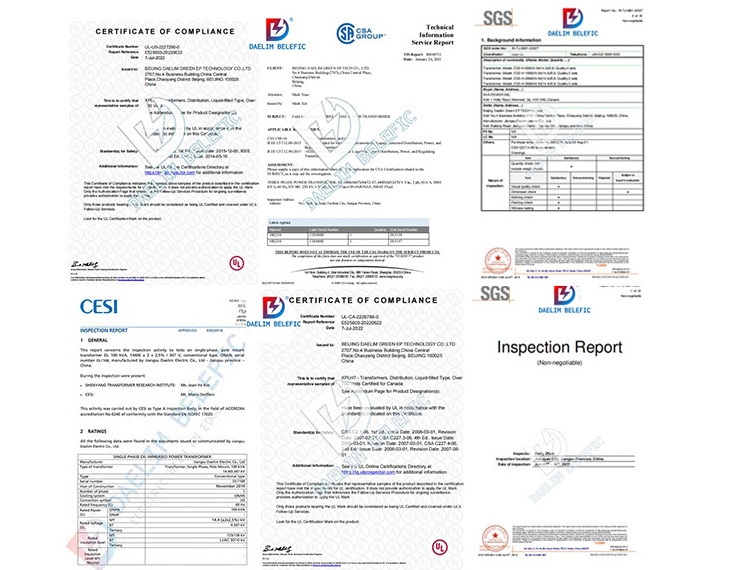

High quality and fast delivery

Daelim has a strict quality control system to ensure the high quality of each transformer. There are also UL third -party inspection agencies to conduct supervision factories every three months. Therefore, you can fully trust the transformer of Daelim.The production time of conventional power distribution transformers is 6-8 weeks

Pad-mounted Transformer Specifications

Click Here For Technical Solutions

Pad-mounted Transformer Standard Feature

Quality System ISO 9001 certified

Meet DOE Energy Efficiency Standard or exceeds ANSI/IEEE and NEMA standards

Tank coating exceeds IEEE Std C57.12.28TM-2005 and IEEE Std C57.12.29TM-2005 standards (stainless steel units only)

Full compliance with IEEE Std C57.12.28TM-2005 standard enclosure integrity requirements

UL/cUL Listed

Pressure relief device

Fluid fill and drain provisions

Laser engraved nameplate

Floating lock pocket for easy alignment

Decal bushing designations

Welded domed tank cover

Optional Accessories

•

Multiple voltages or taps

•

Externally-operable multiple voltage or tap changer switches for

safe operation

• Stainless steel tank, tank bottom, sill, door, and/or hardware

• Service entrance in sill

• Various spades and terminals available for secondary bushings

• Various other designations available, e.g., kVA, voltages, fuse

number

• High-voltage bushing inserts

• Ground connectors

• One piece high-voltage bushings

• Envirotemp™ FR3™ fluid

• Loadbreak switches

• Drain/sampling valve

• Pressure vacuum gauge

• Liquid level gauge

• Temperature gauge

• Canadian Standards Association (CSA) and Consumer Electronics

Association (CEA) designs

Transformer Test

TEST

Daelim performs routing testing on each transformer manufactured including the following tests:

—Ratio, Polarity,and Phase Relation.

—Resistance

—Applied Potential

—Induced Potential

—Loss Test

—Leak Test

Operation tests of all devices: Al electrical and electro-mechanical devices shall be operated both in auto and manual mode for proper sequencing/staging and function.

DESIGN PERFORMANCE TEST

The design performance tests include the following:

* Temperature Rise: Our automated heat run facility ensures that any design changes meet ANSl ® and IEEE ® temperature rise criteria.

* Audible Sound Level: Ensures compliance with NEMAO requirements.

* Lightning Impulse: To assure superior dielectric performance, this test consists of one reduced wave,two chopped waves and one full ave in sequence,precisely simulating the harshest conditions.

* Other perfomance tests such as short-cicuit capability test,liting and moving devices test can be execuled while specified by the customer.

* Temperature Rise: Our automated heat run facility ensures that any design changes meet ANSl ® and IEEE ® temperature rise criteria.

* Audible Sound Level: Ensures compliance with NEMAO requirements.

* Lightning Impulse: To assure superior dielectric performance, this test consists of one reduced wave,two chopped waves and one full ave in sequence,precisely simulating the harshest conditions.

* Other perfomance tests such as short-cicuit capability test,liting and moving devices test can be execuled while specified by the customer.

Hot Searches