- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

360*450*460mm

-

Weight:

-

600 KG

-

Product name:

-

Adjustable magnetic separator

-

Model:

-

XCG-120

-

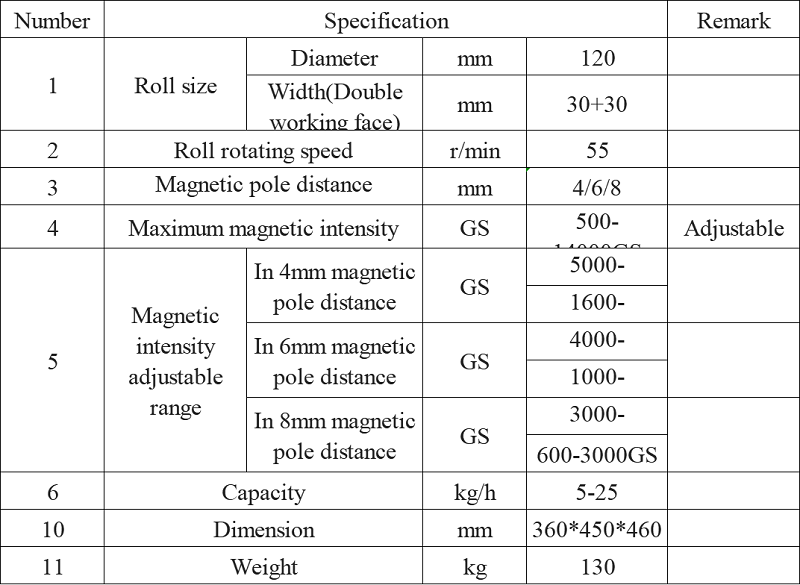

Drum diameter:

-

120

-

Price:

-

Negotiation

-

Quality:

-

High Reputation

-

Capacity:

-

5-25kg/h

-

Max intensity:

-

14000GS

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Jinchuan

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

360*450*460mm

-

Weight:

-

600 KG

-

Product name:

-

Adjustable magnetic separator

-

Model:

-

XCG-120

-

Drum diameter:

-

120

-

Price:

-

Negotiation

-

Quality:

-

High Reputation

-

Capacity:

-

5-25kg/h

-

Max intensity:

-

14000GS

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

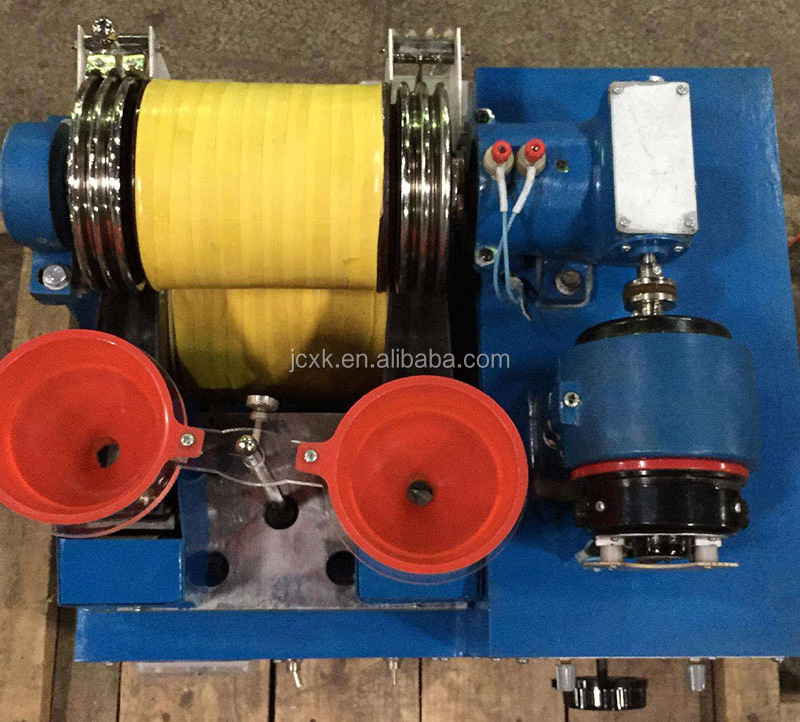

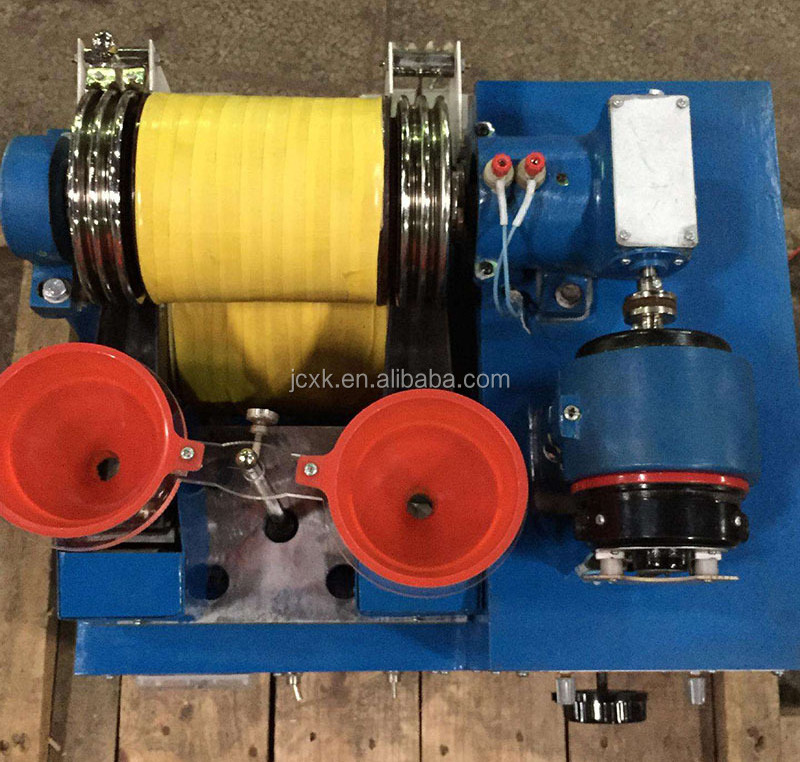

Introduction

XCG-120 roller dry magnetic separation machine applies to the metallurgical, geological, building materials and other scientific research units and geological team, dry separation of weak or strong magnetic minerals, the machine uses double closed working face by magnetic circuit, excitation system, mechanical drive system and products to mine sweeping and collecting system composed of electromagnetic vibration feeder, a mineral to the sub district, by controlling the excitation current size, the mineral through magnetic gap automatically into the magnetic material and non-magnetic material discharged out of the machine, in order to achieve the purpose of separation

Stracture

The magnetic separator consists of the excitation system, the transmission mechanism, the ore feeding system and the cleaning and collecting parts of the product.

(1) excitation system: composed of fixed pole, roller magnetic pole and excitation winding and excitation DC power on both sides, the upper and lower two poles are parallel arranged. Two rollers with a diameter of 120 mm and the lower plane magnetic pole form a closed magnetic loop. Two the working distance of the magnetic pole can be adjusted by adding or reducing the cushion plate. Through the adjustment of the voltage of high-voltage machine made of silicon element supply fixed excitation winding and the DC current supply brush roller rotation pole excitation winding, can be smoothly from 2 amps to the rated value, in order to adapt to the separation of different types of ore the machine requires a range of magnetic field strength can be divided into two kinds of strong magnetic field and weak magnetic field, by the panel field selection switch selection. When the separation interval is 4 mm, the magnetic field selector switch is placed in a strong magnetic field. When the excitation current is 2 AMPERES, the large magnetic field strength is no less than 14000 OE (1110RA/m).

(2) Transmission structure: consists of electromagnetic vibration feeder, ore storage funnel and ore feeding cone and baffle. The electromagnetic vibration feeder can control the amplitude of the electromagnetic vibration feeder to meet the needs of different ore particles by adjusting the two lines around the panel to control the amplitude of the electromagnetic vibration feeder. In order to adjust the speed of ore feeding, the ore bearing cone with different sizes can be used. In normal ore feeding, the baffle is adjusted to about 45 degrees, so that the ore flow is evenly distributed into the ore slot. If the ore is stopped in the middle of the way, the baffle can be stopped at the level near the ore mouth, and the ore can be stopped.

(3) Product cleaning and collection part by the product receiving chute, separating plate, hammer and mineral consisting of container cleaning brush. In the middle of the product receiving tank, a separator, magnetic products are drawn on the roll, the partition of the chute into the product of magnetic ore separator filled container, the inclination of the movable groove side by screwing the handle can be adjusted, non magnetic products by lower ore groove into another containing ore container.

1Q:What information should customers give us in order to let us provide more efficient & suitable quotation and assistance.

A:Which product and specification do you want?

B:What's the purpose of buying the machine?

C:What is the capacity per hour?

2Q:What about the price?

A:We would give you a cheapest price according to the model and quantity.

3Q:what's the payment terms?

A:Negotiable

4Q:Are customized products accepted?

A:Your idea, your choice, we design. Nothing is impossible. We are always waiting for you here, where are you.

5Q:Why choose Jinchuan mineral eauipment co., ltd ?

A:We are the professional manufacturer in China for such industry.

B: We have R&D team who can design fully new and automatic machine to update the processing.

C: Excellent pre-sale and after-sale services. If you give me a chance, you will get it Extremely worthy value.

About Jinchuan mineral equipment Co.,Ltd

We are a high-tech company which was founded in 2003. We specialize in the research and production of mineral processing equipment.

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator,electrostatic separator, vibrating screen, gold pan, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.

We have a strong R&D department and experienced engineers. We can design and make OEM/ODM products according to your ideas and samples.

Quality control is more an action than a slogan. Strict quality control is implemented in all aspects of operations to meet the high standards of top-tier customers. This philosophy has permeated all levels of the production process, covering:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

Through many years of development, our company has become a large-scale enterprise with research, production, assembly and marketing capabilities. Our products are distributed all over the world.

We look forward to receiving your inquiries!

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Container

|

40HQ/40GP/20GP

|

|

|

Load Port

|

Xiamen , Shenzhen,or as request

|

|

|

Trade term

|

FOB,EXW,CIF,CFR

|

|

|

Delivery time

|

Within 35 days after recieve 30% deposit,balance before loading

|

|