- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3kw

-

Min. Lifting Height:

-

300mm

-

Table Size:

-

1200*1200mm or custom

-

Overall Dimensions:

-

custom to your needs

-

Weight:

-

1000 kg

-

Marketing Type:

-

Hot Product 2023

-

Table diameter:

-

4m 4.5m 5m 5.5m 6m 7m

-

Equipment height:

-

170-350mm

-

Rotation period:

-

0.2-1rpm(Frequency)

-

loading capacity:

-

2000-8000kg

-

Motor Power:

-

0.75kw /1.5kw

-

Power supply:

-

AC220V/AC110V/AC380V

-

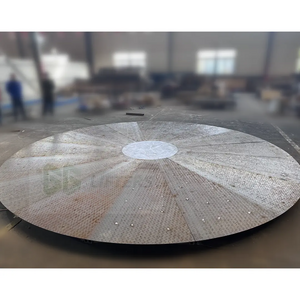

platform material:

-

plywood plate/patterned steel plate/patterned aluminum alloy plate

-

way to control:

-

Controlled/remote control; forward/reverse/stop

-

Additional mode:

-

Remote control/angle control/stop control

-

Application:

-

car lift 360 degree display rotating hydraulic garage car turntable

Quick Details

-

Warranty:

-

3 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

chaokong

-

Power:

-

3kw

-

Min. Lifting Height:

-

300mm

-

Table Size:

-

1200*1200mm or custom

-

Overall Dimensions:

-

custom to your needs

-

Weight:

-

1000 kg

-

Marketing Type:

-

Hot Product 2023

-

Table diameter:

-

4m 4.5m 5m 5.5m 6m 7m

-

Equipment height:

-

170-350mm

-

Rotation period:

-

0.2-1rpm(Frequency)

-

loading capacity:

-

2000-8000kg

-

Motor Power:

-

0.75kw /1.5kw

-

Power supply:

-

AC220V/AC110V/AC380V

-

platform material:

-

plywood plate/patterned steel plate/patterned aluminum alloy plate

-

way to control:

-

Controlled/remote control; forward/reverse/stop

-

Additional mode:

-

Remote control/angle control/stop control

-

Application:

-

car lift 360 degree display rotating hydraulic garage car turntable

car lift platform

360 °

rotating

display

garage car turntable

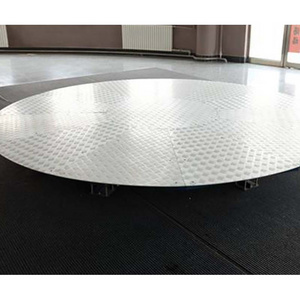

The Vehicle Turntable is an efficient and cost-effective method of turning a vehicle. The turntable requires significantly less

space than a turning bay and is operated by a remote from within the vehicle. The turntable rotates in either direction and can be

stopped at any position. Our standard turntable is 4 metres in diameter and this is suitable for the vast majority of vehicles.

Custom sizes are also available.

A turntable is most useful in properties with:

* Difficult access

* Limited space for turning

* Steep drives

* Busy roads making reversing dangerous

* Multiple dwellings with limited parking

* Limited space which is better used for other purposes

space than a turning bay and is operated by a remote from within the vehicle. The turntable rotates in either direction and can be

stopped at any position. Our standard turntable is 4 metres in diameter and this is suitable for the vast majority of vehicles.

Custom sizes are also available.

A turntable is most useful in properties with:

* Difficult access

* Limited space for turning

* Steep drives

* Busy roads making reversing dangerous

* Multiple dwellings with limited parking

* Limited space which is better used for other purposes

Lifting stage operating procedures

1. The lifting stage has been inspected and debugged before leaving the factory, and all technical indicators meet the design requirements. When using it, it only needs to be connected to the power supply, and the hydraulic and electrical systems do not need to be adjusted.

2. Before using the stage, carefully check the hydraulic and electrical systems, and use it only after there is no leakage or naked leakage.

3. When the lifting stage is in use, the base should be firmly supported on a solid ground.

4. The lifting stage can be operated with people only after 1-3 empty runs.

5. The center of gravity of the manned person should be at the center of the workbench as much as possible.

In addition to safe operation, the lifting stage also needs regular daily maintenance. The daily maintenance of the lifting stage is as follows:

1. Always check the connection of each part, and tighten it if it is loose. The tightness of the connecting bolts of the body should be checked when the body is under pressure (the method of rotating the arm can be used to cause the state of compression), and all connecting pins must have cotter pins and must be fully opened.

2. The brakes of each part should be regularly checked and adjusted to the gap between the brake shoe and the brake wheel to ensure flexibility and reliability. There should be no dirt on the friction surface, and if there is dirt, it must be washed off with gasoline or thinner.

3. Lubrication and hydraulic oil of various parts such as reduction box, gearbox and external gear are carried out according to the requirements in the lubrication table.

4. Always check all wires and cables for damage. The damaged part should be bandaged and replaced in time

5. Frequently check whether all parts are operating normally and whether there is noise. If any fault is found, it must be eliminated in time.

6. When installing, disassembling and adjusting the slewing mechanism, pay attention to ensure that the centerline of the slewing mechanism reducer is parallel to the centerline of the gear, the meshing surface is not less than 70%, and the meshing clearance should be suitable.

7. When the motor is overheated, stop it in time, and continue to run after troubleshooting. The motor bearings must be well lubricated.

8. The contact surface of each part of the brush should be kept clean, and the pressure of the brush should be adjusted so that the contact area is not less than 50%.

9. The control boxes, distribution boxes, etc. are always kept clean, and the dust on the electrical equipment is cleaned in time. Ensuring regular maintenance of the lifting platform can not only prevent accidents, but also greatly enhance the working efficiency of the lifting platform. Welcome customers to come and buy our products.

Jinan CHAOKONG Electrical Equipment Co., Ltd.

is a new cultural technology cross-border company. It mainly provides non-standard

mechanical design, production and non-standard automation control integrated solutions for various theaters and performance

venues, as well as large-scale performance special devices, special equipment and control system engineering projects. The company

is committed to the integration and innovation of culture and science and technology, and provides solutions and implementation

services integrating research and development, equipment system integration and operation management of key technical equipment in

the fields of cultural tourism, entertainment performances and art displays.

Hot Searches