- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

9500 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Impact Crusher Machine

-

Keyword:

-

Rock Stone Crusher Machinery

-

Function:

-

Mining Crusher Equipment

-

The Machines classification:

-

Building Stone Production Line

-

Quality:

-

High-Quality

-

Applicaton:

-

Mining Quarry Stone Crushing Plant

-

Advantage:

-

Higher Efficiency

-

Price:

-

Attractive

-

Installation:

-

Online Video Guide Installation

-

Crusher type:

-

Impact Rock Crusher

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Shaolin Heavy Machinery Factory

-

Dimension(L*W*H):

-

2400x1558x2660

-

Weight:

-

9500 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Impact Crusher Machine

-

Keyword:

-

Rock Stone Crusher Machinery

-

Function:

-

Mining Crusher Equipment

-

The Machines classification:

-

Building Stone Production Line

-

Quality:

-

High-Quality

-

Applicaton:

-

Mining Quarry Stone Crushing Plant

-

Advantage:

-

Higher Efficiency

-

Price:

-

Attractive

-

Installation:

-

Online Video Guide Installation

-

Crusher type:

-

Impact Rock Crusher

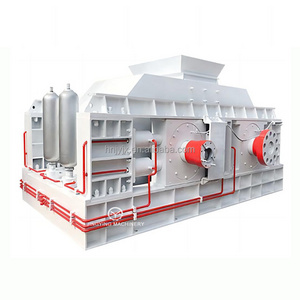

Equipment Introduction

Introduction to impact crusher

The impact crusher, also known as the impact crusher, is a new type of crusher produced by our company based on the impact crusher at home and abroad, combined with current excellent crushing technology. It is mainly used for crushing small and medium-sized cement raw materials and clinker, and for crushing other medium hard ores such as construction sand, iron ore, sandstone, gypsum, coal gangue, and lump coal. It has the characteristics of high crushing ratio, low energy consumption, smooth operation, simple structure, and convenient operation and maintenance. It can truly achieve multifunctional, efficient, and low-cost functions.

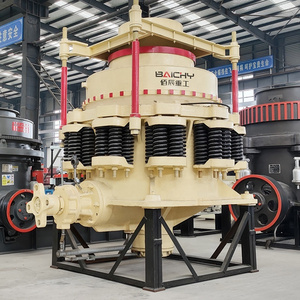

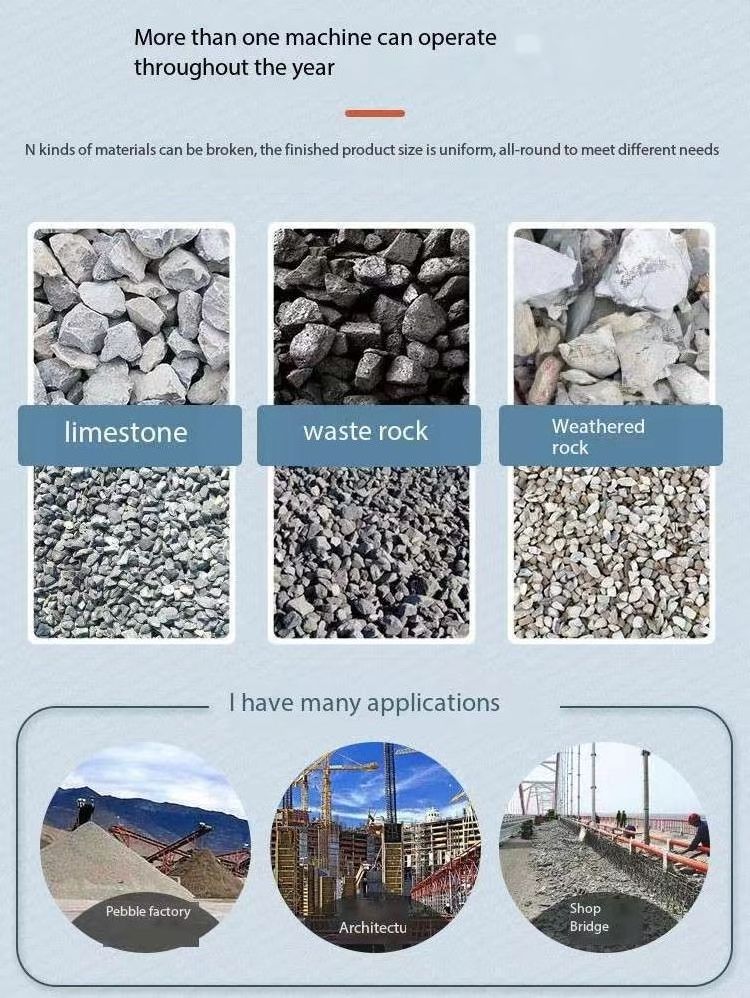

Main application:

Impact crusher can handle materials with side length below 100-500mm, with compressive strength up to 350 MPa, with large crushing ratio, the crushed materials are cubic particles and other advantages. Widely used in building materials, ore crushing, railroads, highways, energy, transportation, energy, cement, mining, chemical and other industries for fine crushing materials. Its discharge size can be adjusted, and the crushing specifications are diversified.

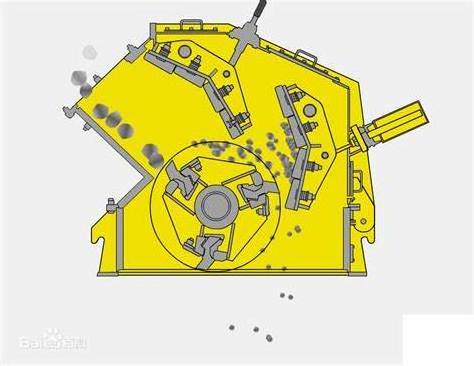

Working Principle

:

Impact crusher is a kind of crushing machine which utilizes impact energy to crush materials. When the machine works, driven by the motor, the rotor rotates at a high speed, the material enters the plate hammer area, crushes with the plate hammers on the rotor, and then it is thrown to the counterattack device to be crushed again, and then bounces back to the plate hammer area to be crushed again from the counterattacking liner, and the process repeats, and the material enters into the first, second, and third impact chambers to be crushed again from big to small, until the material is crushed to the required granularity, and then discharged from the discharge port. Discharge

Product Benefits:

1. The impact crusher is more effective in handling materials with high moisture content, effectively preventing material blockage.

When dealing with materials with high water content, the feeding chute and impact plate of the impact crusher can be equipped with heating devices to prevent material adhesion. The impact crusher does not need to be equipped with a bottom sieve plate, effectively preventing blockage.

2. The impact crusher is suitable for a wider range of material hardness.

The plate hammer of the impact crusher adopts a mechanical clamping structure, firmly fixed on the rotor, and the rotor has a large moment of inertia when rotating with the rotor. Compared with the hammer crusher (hammer head suspension type), the rotor of the impact crusher has greater power, is suitable for crushing harder materials, and has lower energy consumption.

3. Convenient and flexible adjustment of discharge volume, with a wide range of adjustment

The impact crusher can adjust the discharge size in various ways, such as adjusting the speed of the rotor, adjusting the gap between the impact plate and the grinding chamber, etc. The gap can be adjusted mechanically or mechanically. The gap can be adjusted mechanically or hydraulically, and the hydraulic adjustment system can be conveniently adjusted through on-site operation buttons or transportation control systems.

4. Wear and tear of vulnerable parts are small, and the metal utilization rate is high.

The wear of the impact crushing hammer only occurs on the side facing the material. When the rotor speed is normal, the feed will fall onto the surface of the hammer (striking surface), and the back and side of the hammer will not wear. Even the side facing the material rarely wears out. And the bottom grinding rod is easy to replace. The metal utilization rate of the impact crusher can reach up to 45% -48%.

5. The replacement of spare parts for the impact crusher is convenient, and the maintenance cost is correspondingly reduced.

The rotor of the impact crusher only has 6 hammers installed, and it is easy to replace the hammers with specially designed tools. Replacing a set of hammers only requires one shift.

Specification

|

Model number

|

Norm

|

Inlet size

(mm)

|

Feed size

(mm)

|

processing capability

(t/h)

|

Motor power

(Kw)

|

Weights

(t)

|

Overall Dimension

(mm)

|

|

PF-1007

|

1000x700

|

400x730

|

≤300

|

30-50

|

37-55

|

9.5

|

2400x1558x2660

|

|

PF-1010

|

1000x1050

|

400x1080

|

≤350

|

50-80

|

55-75

|

12.2

|

2400x2250x2620

|

|

PF-1210

|

1250x1050

|

400x1080

|

≤350

|

70-120

|

110-132

|

14.9

|

2690x2338x2890

|

|

PF-1214

|

1250x1400

|

400x1430

|

≤350

|

110-180

|

132-160

|

18.6

|

2690x2668x2890

|

|

PF-1315

|

1320x1500

|

860x1520

|

≤500

|

160-250

|

180-260

|

19.3

|

3096x3273x2667

|

|

PF-1320

|

1320x2000

|

860x2030

|

≤500

|

160-350

|

300-375

|

28

|

3096x3560x3185

|

|

PF-1520

|

1500x2000

|

1315x2040

|

≤700

|

300-500

|

400-450

|

42.8

|

3890x3560x3220

|

Packing&Delivery

Company Site Pictures

Customer Visits

Hot Searches